ofh gasket

Understanding OFH Gaskets Importance, Types, and Applications

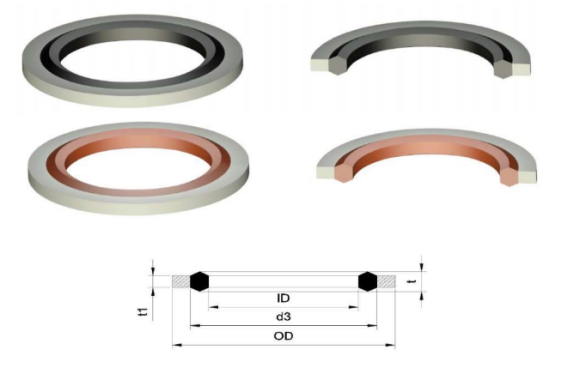

Gaskets are essential components in various engineering and manufacturing processes. They serve as seals between two surfaces, preventing leaks and maintaining pressure in systems ranging from automotive engines to pipelines. One particular type of gasket that has gained attention is the OFH gasket, or Oil and Fuel Hose gasket. This article delves into the definition, significance, types, and applications of OFH gaskets.

What is an OFH Gasket?

An OFH gasket is specifically designed for applications involving oil and fuel hoses. These gaskets act as a barrier to prevent leakage and ensure the proper flow of liquids in machinery and engines. Typically made from durable materials such as rubber, silicone, or composite materials, OFH gaskets are engineered to withstand harsh chemical environments and extreme temperatures. Their primary function is to provide a reliable seal that can cope with the pressure and heat generated in engine compartments and fuel systems.

Importance of OFH Gaskets

The role of OFH gaskets cannot be understated. In automotive engines, for example, they help to ensure the integrity of the fuel system, preventing leaks that could lead to catastrophic failures or hazardous conditions. The weakness of a gasket often results in fuel spilling into unwanted areas, potentially causing fires or environmental contamination. By maintaining a tight seal, OFH gaskets contribute to the overall safety and efficiency of engines and other machinery.

Moreover, the performance of an engine heavily relies on the quality of the gaskets used. A compromised gasket can lead to diminished engine performance, reduced fuel efficiency, and increased emissions. Therefore, utilizing high-quality OFH gaskets in engine assemblies and fuel systems is crucial for automotive manufacturers, mechanics, and end-users alike.

Types of OFH Gaskets

There are various types of OFH gaskets tailored for specific applications and environments. Here are some common types

ofh gasket

1. Flat Gaskets These are simple, flat seals designed to cover a specific area of contact. They are often used in applications where space is limited or where a smooth surface is essential.

2. Spiral Wound Gaskets Made from alternating layers of material, spiral wound gaskets are designed to provide a robust sealing solution, especially in high-pressure applications. They combine flexibility with strength, making them ideal for oil and fuel hoses.

3. Ring Gaskets These gaskets are shaped in a circular form and are predominantly used in situations where a strong seal is required, such as high-pressure fuel lines or oil pipes. Their design allows for even distribution of pressure around the entire circumference.

4. Composite Gaskets These gaskets are made from a combination of materials to enhance their durability and resistance to various chemical exposures. They are often used in more complex applications where multiple environmental factors are at play.

Applications of OFH Gaskets

OFH gaskets have widespread applications beyond automotive use. They are utilized in various industries, including

- Aerospace Gaskets in aircraft engines are critical for preventing fuel leaks and ensuring safe operations. - Marine Boats and ships rely on OFH gaskets to maintain integrity in their fuel systems, especially under challenging marine environments. - Industrial Equipment Manufacturing machinery that utilizes oil or fuel will often implement OFH gaskets to ensure seamless operations. - Chemical Processing In facilities that handle hazardous materials, OFH gaskets play a vital role in preventing leakage and maintaining worker safety.

Conclusion

In conclusion, OFH gaskets are a vital component in a multitude of applications that involve the handling of oil and fuel. Their ability to create effective seals under harsh conditions is fundamental to the performance and safety of various machinery and vehicles. Understanding the significance and types of OFH gaskets aids manufacturers and engineers in making informed decisions to optimize their systems. As technological advancements continue to improve gasket design and materials, we can expect OFH gaskets to play an even more crucial role in engineering and manufacturing industries in the future.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories