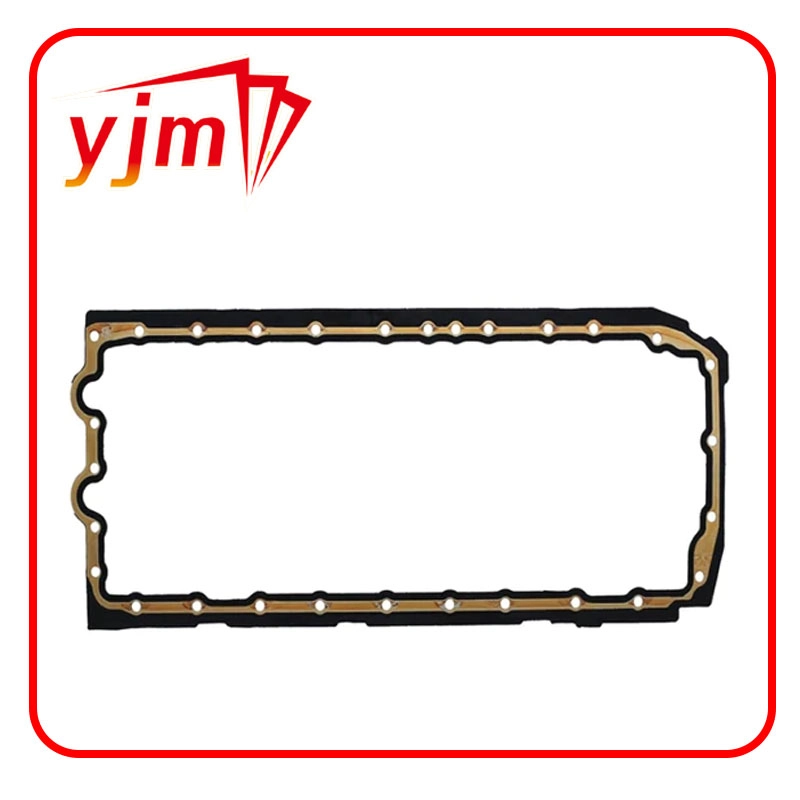

non metallic flat gasket

Understanding Non-Metallic Flat Gaskets Essential Components for Sealing Applications

Non-metallic flat gaskets play a crucial role in a variety of industries, including automotive, manufacturing, and energy. These gaskets serve as essential sealing solutions that prevent leaks and ensure the efficient operation of machinery and equipment. In this article, we will explore the materials, applications, advantages, and considerations associated with non-metallic flat gaskets.

What Are Non-Metallic Flat Gaskets?

Non-metallic flat gaskets are sealing devices made from materials that do not contain metal. They are usually flat and used to fill the space between two surfaces, which could be flanged joints, cylindrical surfaces, or other configurations. These gaskets can be crafted from a variety of materials such as rubber, plastics, composites, and more, thereby making them versatile for different applications.

Common Materials Used

1. Rubber Natural rubber and synthetic rubber (like neoprene and nitrile) are commonly used in the manufacturing of non-metallic gaskets. These materials offer excellent flexibility, resilience, and sealing capabilities, especially in applications involving low to moderate temperatures.

2. PTFE (Polytetrafluoroethylene) Known for its high chemical resistance and thermal stability, PTFE is often used in harsh environments. PTFE gaskets are suitable for aggressive chemicals, making them ideal for the chemical processing and pharmaceutical industries.

3. Composites Fiber-reinforced composites combine materials to enhance strength, temperature resistance, and chemical compatibility. These gaskets are suitable for high-pressure applications and provide superior sealing properties.

4. Graphite Flexible graphite gaskets are known for their ability to maintain a seal under high temperatures and pressures. They are often utilized in applications such as steam systems, where traditional materials might fail.

Applications

Non-metallic flat gaskets are widely used in various industrial contexts. They are essential in

non metallic flat gasket

- Automotive Engines Sealing components in engines to prevent oil and coolant leaks. - Piping Systems Ensuring leak-proof connections in water and gas pipelines. - Chemical Equipment Protecting against chemical leaks in tanks, valves, and pumps. - Food and Beverage Industry Complying with hygiene standards while ensuring seals that prevent contamination.

Advantages of Non-Metallic Flat Gaskets

2. Chemical Resistance Many non-metallic materials provide excellent resistance to chemicals, reducing the risk of degradation over time.

3. Ease of Installation These gaskets are generally lighter and easier to handle, which simplifies the installation process.

4. Cost-Effectiveness Non-metallic gaskets are often less expensive than their metallic counterparts, providing a budget-friendly sealing solution.

5. Temperature Resistance Various materials can withstand a specific range of temperatures, making non-metallic gaskets adaptable for both low and high-temperature environments.

Considerations

While non-metallic flat gaskets offer many benefits, it’s essential to consider factors such as material compatibility with the fluids being sealed, the operating temperature, and pressure conditions. Additionally, proper installation is critical to ensure optimal performance and longevity of the gasket.

Conclusion

Non-metallic flat gaskets are vital components that serve to seal connections across a range of industrial applications. Their diverse material options, coupled with cost-effectiveness and ease of use, make them an excellent choice for engineers and maintenance professionals alike. Understanding the properties and suitable applications for non-metallic gaskets can lead to more effective sealing solutions and enhanced operational efficiency in various fields. As technology advances and materials improve, the role of non-metallic gaskets will only continue to expand, solidifying their importance in the industrial world.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories