national oil seals

Understanding National Oil Seals Essential Components in Machinery

Oil seals, often referred to as national oil seals, are crucial components in machinery that play a significant role in maintaining the integrity and longevity of various mechanical systems. These seals are designed to contain lubricants and prevent the leakage of fluids, thereby reducing friction between moving parts and protecting machinery from contaminants. In this article, we will explore the importance, types, applications, and maintenance of national oil seals.

The Importance of Oil Seals

In any mechanical assembly, the presence of oil seals is essential for several reasons. First and foremost, they help in retaining lubricants within a system. Lubricants reduce friction among moving components, which is vital for the efficient operation of machines. Without oil seals, lubricants would escape, leading to increased wear and tear on parts, overheating, and potential machinery failure.

Moreover, oil seals protect the internal components of machinery from external contaminants like dirt, dust, and moisture. These foreign particles can cause significant damage to critical components, leading to a decrease in performance and an increase in maintenance costs. By preventing these contaminants from entering the system, oil seals play a key role in prolonging the life of the machinery.

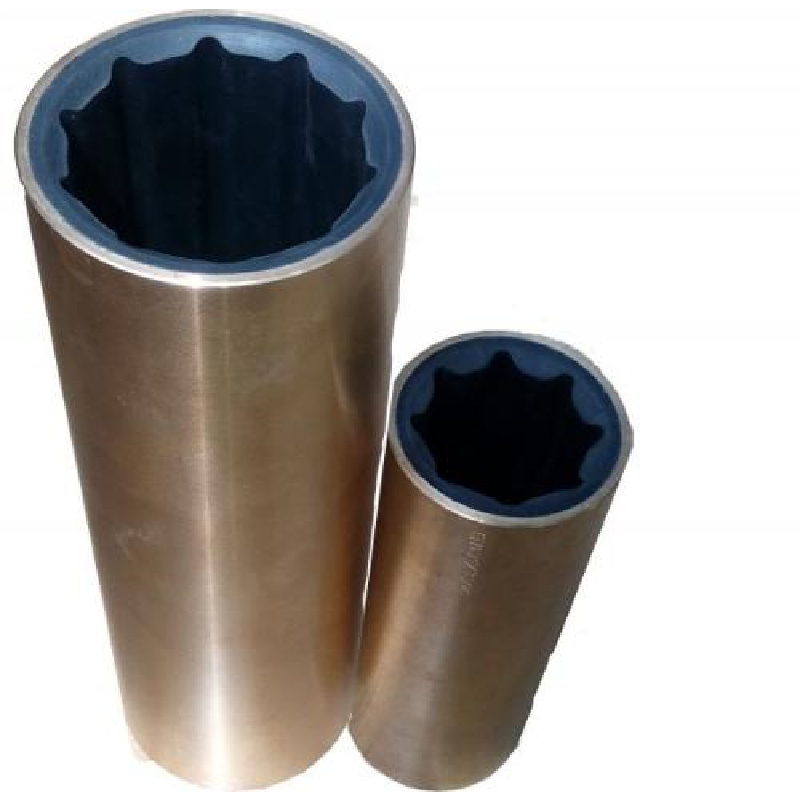

Types of National Oil Seals

National oil seals come in various types, each designed for specific applications and environments

. The most common types include1. Rotary Oil Seals These are used in rotating machinery, such as engines and gearboxes. They typically feature a lip design that creates a tight seal against the shaft, preventing lubricant leakage while allowing the shaft to rotate freely.

2. Static Oil Seals Used in applications where there is no relative motion between the sealing surfaces, static oil seals are designed to prevent fluid leakage in stationary components.

3. Double Lip Seals These seals have two sealing lips that provide an additional layer of protection against fluid loss and contaminants. They are often used in applications where enhanced sealing is required.

4. V-Ring Seals A type of static seal, V-ring seals are designed to seal against rotating shafts while also accommodating angular misalignments. This makes them ideal for applications with variable alignment.

national oil seals

5. Cam Profile Seals These seals are used in dynamic applications and offer a unique design that enhances sealing performance in fluctuating pressures.

Applications of Oil Seals

National oil seals are used in a wide range of applications across various industries. In the automotive sector, they are commonly found in engines, transmission systems, and wheel bearings. Their role in preventing oil leakage and protecting against contamination is critical in ensuring the reliability and efficiency of vehicles.

In industrial machinery, oil seals are essential components in hydraulic systems, pumps, and compressors. They ensure that hydraulic fluids stay contained, preventing pressure loss and ensuring optimal performance.

Moreover, national oil seals are also utilized in aerospace, marine, and agricultural equipment, showcasing their versatility and importance across different sectors.

Maintenance and Replacement

Regular maintenance of oil seals is pivotal in ensuring their effectiveness. Signs of wear or damage, such as oil leaks or abnormal noise, should not be ignored. It is essential to inspect oil seals periodically and replace them as needed.

When replacing oil seals, it is crucial to select the correct type and size for the specific application. Incorrect seals can lead to improper sealing, resulting in fluid leakage and costly repairs. Always consult manufacturer guidelines or seek professional assistance when in doubt.

Conclusion

National oil seals are a vital component in maintaining the efficiency and longevity of machinery across diverse applications. Their ability to retain lubricants and protect against contaminants makes them indispensable in various industries. Understanding the types of oil seals, their applications, and the importance of regular maintenance will ensure optimal performance and reliability of mechanical systems. As technology continues to advance, the design and materials used for oil seals will likely evolve, further enhancing their effectiveness in protecting machinery and reducing maintenance costs.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories