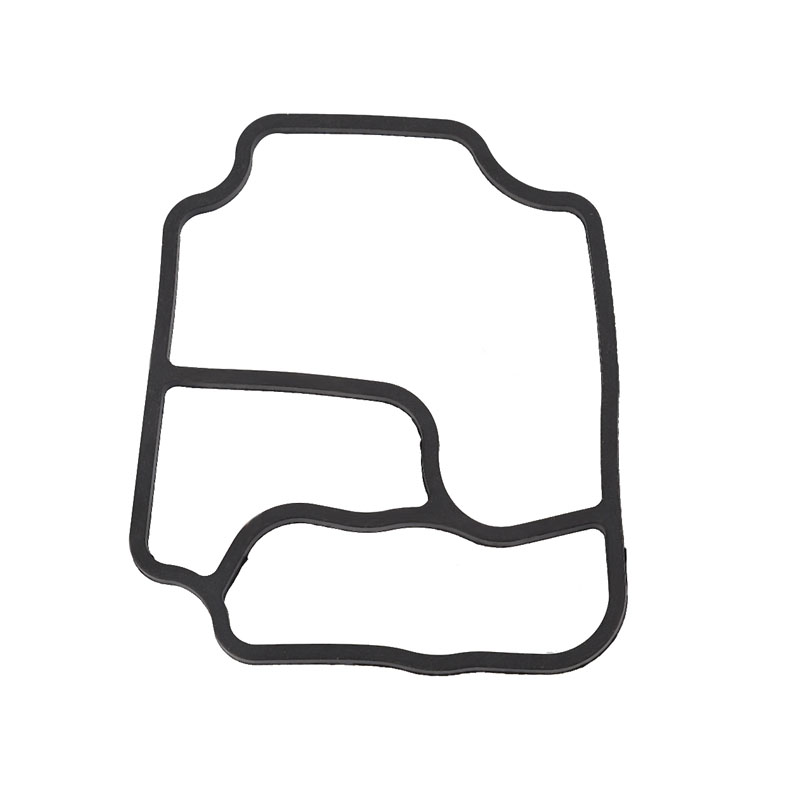

motor shaft seal

Understanding Motor Shaft Seals Importance and Applications

Motor shaft seals are critical components in various machinery and equipment, playing a vital role in maintaining operational efficiency and prolonging the lifespan of mechanical systems. These seals are designed to prevent the leakage of fluids and contaminants, which can lead to significant damage and inefficiencies in motor performance.

What Are Motor Shaft Seals?

Motor shaft seals, often referred to as rotary shaft seals or oil seals, are circular devices that fit snugly around the shaft of a motor or any rotating element. They typically consist of an elastomeric material, such as rubber, which provides flexibility and resilience, along with metal components that reinforce their structural integrity. The primary function of these seals is to create a barrier between the rotating shaft and the stationary housing, preventing the escape of lubricants and the entry of dirt, dust, or moisture.

Importance of Motor Shaft Seals

1. Preventing Leakage One of the primary roles of motor shaft seals is to prevent lubrication leakages. Lubricants are essential for reducing friction between moving parts, and their loss can lead to overheating and increased wear, ultimately resulting in equipment failure.

2. Protecting Machinery Contaminants such as dust, dirt, and water can wreak havoc on motor performance. By sealing the area around the shaft, these seals protect the internal components from external elements that may cause corrosion, abrasion, or other forms of damage.

3. Enhancing Efficiency A well-sealed motor operates more efficiently. When lubricants are contained effectively, motors can run cooler and more smoothly, reducing energy consumption and enhancing overall performance.

4. Extending Lifespan By preventing leaks and blockades from external contaminants, motor shaft seals contribute to the longevity of equipment. This reduced wear and tear translates into lower maintenance costs and longer service intervals.

motor shaft seal

Applications of Motor Shaft Seals

Motor shaft seals are used in various applications across multiple industries, including

- Automotive In cars and trucks, these seals are critical for preventing oil leaks from the engine and transmission. They are commonly found in crankshaft and camshaft applications.

- Industrial Machinery Many machines, such as pumps and conveyors, utilize motor shaft seals to maintain proper operation and prevent costly downtimes.

- Aerospace In aircraft engines, reliability is paramount. Hence, motor shaft seals are engineered to withstand extreme temperatures and pressures.

- Household Appliances Washing machines, dryers, and refrigerators all utilize motor shaft seals to ensure that operational fluids are contained and the machinery operates smoothly.

Conclusion

Motor shaft seals may seem like small components, but their impact on machinery performance and reliability is substantial. Understanding the importance of these seals can help industries maintain their equipment more effectively and prevent unforeseen failures. As technology advances, the design and materials used in motor shaft seals are also evolving, resulting in products that offer improved resistance to wear and a better sealing capacity. For anyone involved in machinery operation or maintenance, recognizing the value of motor shaft seals is crucial for ensuring optimal performance and durability of their equipment. Investing in high-quality seals can lead to significant savings and enhanced operational efficiency in the long run.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories