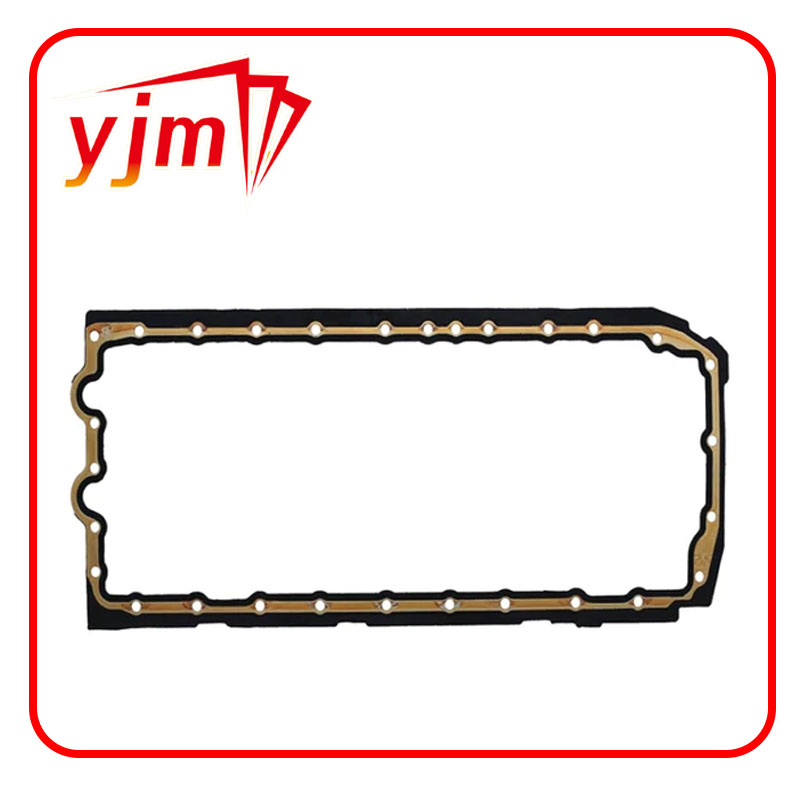

metric bonded seals

Understanding Metric Bonded Seals An Essential Component in Sealing Technology

In the world of engineering and manufacturing, the integrity of a system often hinges on the performance of its sealing components. Among these, metric bonded seals stand out as a vital solution for a variety of applications, particularly in industries such as automotive, aerospace, and oil and gas. Understanding what metric bonded seals are, their composition, benefits, and applications is crucial for engineers and designers seeking reliable sealing solutions.

Metric bonded seals, also known as sealing washers or O-rings, are specialized sealing components designed to provide a leak-proof seal between two surfaces. They typically consist of two main materials a metallic outer ring and an elastomeric inner seal. The metallic ring helps to absorb pressure and provide structural integrity, while the elastomeric material ensures flexibility and resilience, adapting to slight surface irregularities to maintain a tight seal.

One of the defining features of metric bonded seals is their standardized dimensions, which adhere to international metric standards. This standardization simplifies the selection process for engineers and ensures compatibility across a wide range of applications. The seals are available in various sizes and materials, allowing for customization based on specific operating conditions such as temperature, pressure, and the type of fluids being sealed.

metric bonded seals

The benefits of using metric bonded seals are numerous

. Firstly, they effectively prevent leakage of fluids and gases, offering a reliable solution to maintain system pressure and integrity. This is particularly important in high-stakes environments like the oil and gas industry, where even minor leaks can lead to significant safety risks and costly downtimes.Secondly, metric bonded seals exhibit excellent resistance to a variety of chemicals, which allows them to be employed in diverse applications—from hydraulic systems to chemical processing. They also withstand extreme temperatures, making them suitable for both cryogenic and high-temperature environments. This versatility enhances their appeal as a sealing solution across different industries.

Furthermore, the installation of metric bonded seals is relatively straightforward. Their design typically allows them to be easily integrated into existing systems without extensive modification. This ease of use contributes to reduced labor costs and installation time, making them an economical choice for manufacturers.

In conclusion, metric bonded seals play a crucial role in modern sealing technology. Their combination of robust materials, standardization, and versatility positions them as a preferred choice for engineers and manufacturers aiming to ensure leak-proof performance in their systems. As industries continue to evolve and demands for reliable sealing solutions grow, understanding the significance of these seals will remain essential for the advancement of engineering practices. Embracing metric bonded seals is not just about meeting technical specifications; it's about ensuring the safety and efficiency of operations in an increasingly complex industrial landscape.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories