Understanding Metal Bonded Seals for Enhanced Performance and Reliability in Engineering Applications

Understanding Metal-Bonded Seals An Overview

Metal-bonded seals play a crucial role in various applications, particularly in industries that demand high levels of reliability and durability. These seals are designed to provide an effective barrier against liquids, gases, and dust, ensuring the integrity of systems where these materials could cause damage or failure. This article delves into the characteristics, benefits, applications, and considerations of using metal-bonded seals.

What are Metal-Bonded Seals?

Metal-bonded seals are engineered components typically made from a combination of metals and elastomers or other sealing materials. The critical aspect of these seals is the metal-to-metal bonding that enhances their structural integrity. This bond is created using advanced manufacturing techniques that ensure the seal withstands harsh conditions.

Key Characteristics

1. Durability One of the standout features of metal-bonded seals is their impressive durability. They can withstand extreme temperatures, pressures, and aggressive chemical environments. This makes them ideal for applications in aerospace, automotive, and industrial sectors.

2. Versatility Metal-bonded seals can be customized to fit specific applications, including varied shapes and sizes. They can also be designed to accommodate different types of fluids and gases, making them versatile solutions for sealing challenges.

3. Leak Prevention The robust nature of metal-bonded seals allows them to prevent leaks effectively. This is essential in applications where even minor leakages can lead to significant consequences, such as contamination or system failure.

Benefits of Metal-Bonded Seals

- Reduced Maintenance Due to their durability, metal-bonded seals often require less frequent replacement, which translates into lower maintenance costs over time.

- Improved Safety In high-stakes environments, like those found in the oil and gas industry, effective sealing is critical for safety. Metal-bonded seals contribute to safer operational conditions by preventing hazardous leaks.

- Enhanced Performance With superior performance characteristics, these seals can function effectively in extreme conditions where traditional seals may fail. This reliability is paramount in demanding applications.

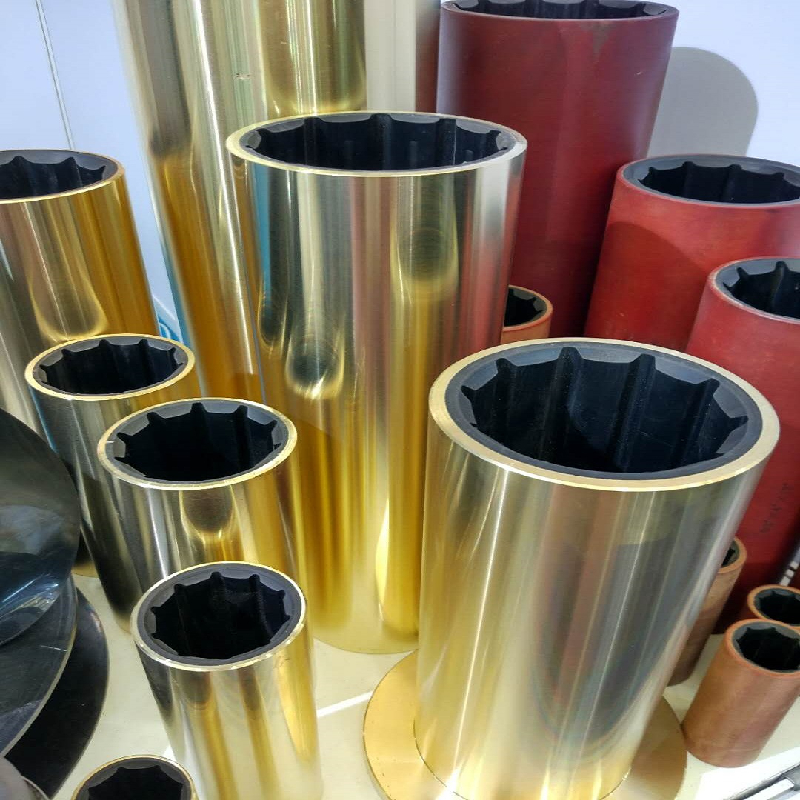

metal bonded seal

Applications of Metal-Bonded Seals

Metal-bonded seals are used in various fields, including

- Aerospace Ensuring the integrity of fuel systems and other critical components where safety is paramount. - Automotive Providing durable sealing for transmission systems and engine components to enhance performance and longevity.

- Industrial Machinery Used in hydraulic systems and pumps, metal-bonded seals help maintain system efficiency and prevent leaks.

Considerations for Using Metal-Bonded Seals

While metal-bonded seals offer numerous advantages, selecting the right seal for a particular application involves careful consideration of several factors

- Material Compatibility It is crucial to choose sealing materials that are compatible with the substances they will contain to prevent degradation.

- Operating Conditions Understanding the environmental conditions—temperature, pressure, and chemical exposure—is essential for selecting an appropriate seal.

- Installation Proper installation is key to ensuring optimal performance. Inadequate installation can lead to premature failure or reduced sealing efficacy.

Conclusion

Metal-bonded seals are indispensable components in various high-demand industries, offering unique advantages that traditional seals may not provide. Their durability, reliability, and adaptability make them vital in maintaining system integrity and safety. As technology advances, the methods of producing these seals continue to improve, promising even greater applications and benefits in the future.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories