mechanical shaft seal

Understanding Mechanical Shaft Seals Function, Types, and Applications

Mechanical shaft seals are vital components in various machinery and industrial applications, designed to prevent fluid leakage along the rotating shafts. These seals are essential for ensuring operational efficiency, reducing maintenance costs, and preventing potential equipment failures. This article delves into the function, types, and applications of mechanical shaft seals.

Function of Mechanical Shaft Seals

The primary purpose of a mechanical shaft seal is to create a barrier that restricts the escape of liquids or gases along the rotating shafts in machinery. This barrier is crucial in maintaining the integrity of the lubricant in rotating systems and preventing the ingress of contaminants. In applications where leaks could lead to environmental hazards or safety concerns, the reliability of these seals becomes paramount.

Mechanical shaft seals typically consist of two main components a rotating ring and a stationary ring. The rotating ring is affixed to the shaft, while the stationary ring is embedded in the machine’s casing. When the shaft rotates, these two rings are pressed together, creating the seal that prevents leakages. The effectiveness of the seal is influenced by several factors, including the materials used, the contact pressure, and the operational conditions such as temperature and pressure.

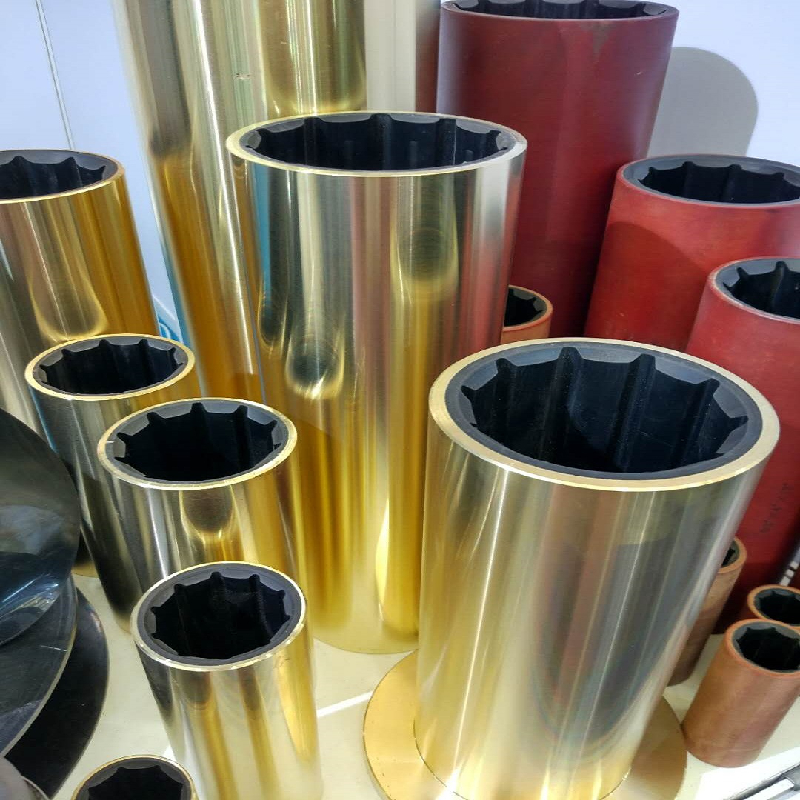

Types of Mechanical Shaft Seals

Mechanical shaft seals come in various types, each designed for specific applications and environments. Some of the most common types include

1. Conventional Mechanical Seals These seals are widely used in pumps and compressors. They can handle moderate pressures and temperatures and are often constructed from materials such as rubber or elastomers, making them suitable for many industrial fluids.

2. Pusher Mechanical Seals These seals feature springs that maintain contact pressure between the sealing faces. They are adaptable to varying temperatures and pressures and are ideal for applications where fluctuations are common.

3. Non-Pusher Mechanical Seals Unlike pusher seals, these designs lack springs. Instead, they rely on the fluid dynamics to maintain their sealing ability. This type is often used in high-speed applications where minimal friction is essential.

4. Cartridge Seals These ready-to-install units simplify maintenance since they come pre-assembled. Cartridge seals are particularly useful in applications where quick replacement is essential to minimize downtime.

mechanical shaft seal

5. Multiple-Spring and Bellows Seals Designed for high-performance applications, these seals can handle extreme pressure and temperature conditions, providing enhanced reliability.

Applications

Mechanical shaft seals are employed in diverse industries, reflecting their versatility. They play an essential role in the following sectors

- Oil and Gas Used in pumps and compressors to contain fluids and prevent leakage, mechanical seals are critical for safety and efficiency in oil and gas extraction.

- Chemical Processing These seals protect against hazardous chemicals, ensuring that toxic fluids do not escape into the environment.

- Water and Wastewater Treatment Mechanical shaft seals in pumps help maintain the integrity of the water supply and minimize leakage in sewer systems.

- Aerospace and Automotive In vehicles and aircraft, these seals are vital for engine protection, ensuring proper lubrication and minimizing wear.

- Food and Beverage Sanitary mechanical seals are necessary in food processing to prevent contamination and ensure compliance with health regulations.

Conclusion

Mechanical shaft seals are indispensable in ensuring the reliability and efficiency of machinery across various industries. Understanding their function, types, and applications is crucial for engineers and technicians to select the appropriate seals for their specific needs. With continued advancements in material science and engineering, the design and performance of mechanical shaft seals are expected to improve, further enhancing their role in modern machinery.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories