mechanical seal shaft

Understanding Mechanical Seal Shafts Their Importance and Functionality

In the realm of machinery and equipment, mechanical seals play a pivotal role in preventing fluid leakage, which is essential for maintaining operational efficiency and ensuring safety. Among the integral components of mechanical seals is the shaft, often referred to as the mechanical seal shaft. This article aims to dwell into what mechanical seal shafts are, their significance in various applications, and the challenges they may face.

What is a Mechanical Seal Shaft?

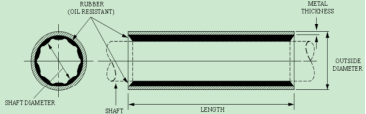

A mechanical seal shaft is the part of a mechanical seal that facilitates the connection between a rotating shaft of an equipment such as pumps, compressors, or mixers and the stationary components of the seal assembly. Typically made from high-quality materials such as stainless steel, carbon, or ceramics, these shafts are designed to withstand the friction, wear, and pressure associated with rotating machinery.

The primary function of a mechanical seal shaft is to maintain a tight seal between the rotating and stationary parts, thus preventing the leakage of fluids - whether these are liquids, gases, or slurries. This is crucial not only for the efficiency of the system but also for compliance with environmental regulations.

The Role of Mechanical Seal Shafts in Different Applications

Mechanical seal shafts are found in numerous applications across various industries, including

1. Chemical Processing In chemical plants, pumps and mixers often involve corrosive or hazardous materials. Mechanical seal shafts ensure that these substances are confined, preventing contamination and potential environmental disasters.

2. Oil and Gas Industry In offshore drilling and production, mechanical seal shafts are employed to handle high-pressure conditions. They are vital for ensuring the safe operation of pumps used in transporting crude oil and natural gas.

3. Water and Wastewater Treatment Pumps used in these systems rely on mechanical seal shafts to keep highly corrosive treated water safely contained, thus preventing leakage that could lead to contamination.

4. Food and Beverage Sanitary mechanical seal shafts are employed in food processing to prevent microbial contamination and product loss, ensuring both safety and taste integrity.

mechanical seal shaft

5. Pharmaceutical Manufacturing Similar to the food industry, maintaining a sterile environment is crucial in pharmaceuticals. Mechanical seal shafts prevent contamination during the manufacturing process.

Challenges Faced by Mechanical Seal Shafts

While mechanical seal shafts are essential components, they are not without challenges. Some common issues include

1. Wear and Tear Over time, friction between the seal faces can lead to wear, compromising the integrity of the seal. Regular maintenance and inspections are crucial to prevent seal failures.

2. Corrosion Depending on the materials handled, mechanical seal shafts can be susceptible to corrosion. Selecting the appropriate materials and coatings can mitigate this risk.

3. Pressure and Temperature Variations Mechanical seal shafts must endure varying pressures and temperatures, which can affect their performance. Designing for the specific operational conditions is essential for reliability.

4. Misalignment Misalignment between the shaft and seal can lead to premature wear or failure. Proper installation and alignment procedures must be followed to ensure optimal performance.

5. Hydraulic Shock Sudden changes in pressure or flow can cause hydraulic shock, which may damage the mechanical seals. Understanding the system dynamics helps in implementing protective measures.

Conclusion

In conclusion, mechanical seal shafts are vital components in a wide array of industries, serving as the first line of defense against fluid leakage. Their proper selection, installation, and maintenance are crucial for the operational reliability of rotating equipment. As industries continue to evolve with increasing pressure and temperature demands, the importance of advanced mechanical seal shafts cannot be overstated. Investing in high-quality materials, regular maintenance, and adopting modern engineering practices will ensure that these components live up to their critical functions, ultimately enhancing machinery performance and safety in a range of applications.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories