Types of Mechanical Oil Seals for Enhanced Performance and Reliability

Understanding Mechanical Oil Seal Types

Mechanical oil seals play a critical role in various industries by preventing the leakage of fluids and protecting internal components from external contaminants. They are designed to seal connections in machinery and equipment, maintaining the integrity of the working environment. This article will explore the different types of mechanical oil seals, their applications, and considerations for their selection.

What is a Mechanical Oil Seal?

A mechanical oil seal is a device used to seal the junctions of machine components that rotate or slide relative to each other. Typically made of elastomers, metal, or composite materials, these seals are crucial in preserving lubrication and preventing contamination, thus ensuring longevity and efficiency of machinery. Efficient sealing solutions not only improve performance but also reduce maintenance costs and downtime.

Types of Mechanical Oil Seals

1. Lip Seals Lip seals, often referred to as rubber oil seals, are among the most common types. They consist of a flexible lip that maintains contact with a rotating shaft. They are effective for preventing oil and grease leakage while also offering some resistance against dust and dirt. Lip seals can be found in various applications, including automotive engines, gearboxes, and industrial machinery.

2. Mechanical Seals Mechanical seals work by creating a barrier between rotating and stationary parts. They consist of two flat surfaces that are pressed together, typically using spring-loaded mechanisms. Mechanical seals are widely used in pumps and mixers and are particularly effective in high-pressure applications. They provide excellent sealing performance and are designed to handle a wide range of fluids, including corrosive substances.

3. O-Ring Seals O-rings are circular seals made from rubber or elastomeric materials. They are simple yet effective and can be used in a variety of applications, including hydraulic systems and pneumatic devices. The O-ring fits into a groove, creating a seal when compressed between two surfaces. While they are versatile, O-rings are typically limited to low-pressure applications.

4. Spin-On Oil Seals Spin-on oil seals are designed for use in automotive applications. They are engineered to fit over the oil filter and are readily replaceable during routine maintenance. These seals provide reliable protection against oil leaks, ensuring the engine remains lubricated efficiently.

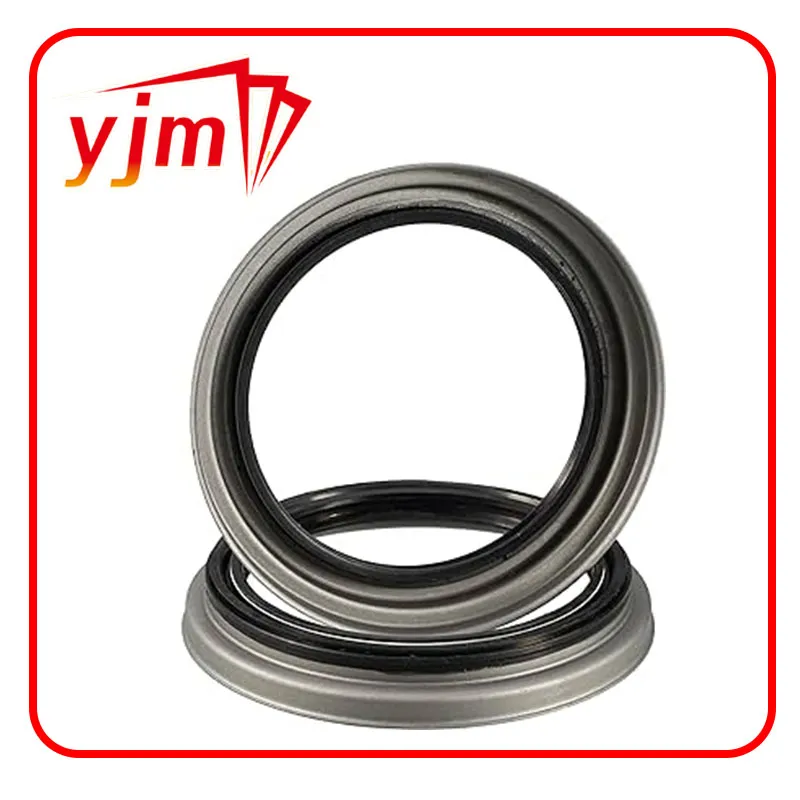

mechanical oil seal types

5. Split Seals Split seals are particularly advantageous in applications where maintenance or replacement of seals can be challenging. As the name suggests, these seals can be split into two halves, allowing for easy installation without requiring disassembly of the entire machinery. They are commonly found in large industrial pumps and rotary equipment.

Factors to Consider When Selecting Mechanical Oil Seals

Choosing the right type of mechanical oil seal is crucial for optimal performance and longevity. Here are several factors to consider

- Operating Environment Understand the conditions in which the seal will operate, including temperature, pressure, and the presence of aggressive chemicals. - Type of Fluid Different seals are suitable for different types of fluids, including oils, water, and harsh chemicals. Selecting a seal that is compatible with the fluid is essential to prevent degradation.

- Speed The rotational speed of the shaft or machinery should be considered, as different seals have varying degrees of performance under different speeds.

- Installation Space Assessing the physical space available for the seal installation is important, especially when dealing with split seals or larger components.

Conclusion

Mechanical oil seals are essential components in ensuring the efficiency and reliability of machinery across various industries. With types ranging from lip seals to mechanical seals and O-rings, it is necessary to understand the specific requirements of your application to select the right seal. By considering the factors mentioned, organizations can enhance machinery performance, reduce maintenance costs, and ensure a longer lifespan for their equipment. As technology evolves, so will the designs and materials used in mechanical oil seals, promoting further advancements in sealing solutions.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories