High-Performance Mechanical Shaft Seals for Reliable Fluid Control

Understanding Mechanical Shaft Seals Functions and Applications

Mechanical shaft seals play a crucial role in a wide array of industrial applications, providing essential functionality in preventing fluid leakage and protecting machinery from contaminants. These seals are predominantly used in rotating equipment such as motors, pumps, and compressors, where a shaft exits a housing or enclosure. The integrity of these seals is paramount, as any failure can lead to operational inefficiencies and costly repairs.

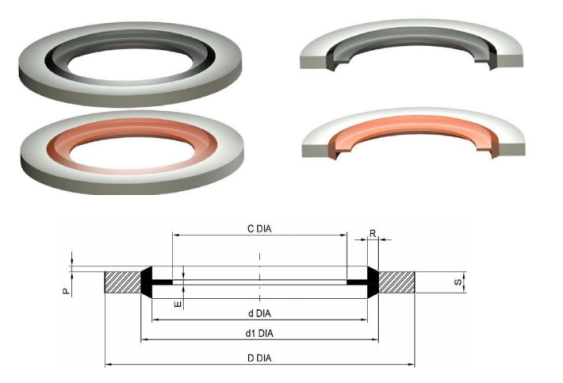

At its core, a mechanical shaft seal comprises two main components a stationary part mounted to the housing and a rotating part attached to the shaft. The interface between these two parts creates a barrier that prevents the escape of fluids, gases, and other materials while allowing the shaft to rotate freely. This dynamic interface uses friction and pressure to maintain a tight seal without compromising the functionality of the rotating shaft.

One of the primary advantages of mechanical shaft seals is their ability to handle high pressures and temperatures

. They can be made from various materials, including elastomers, metals, and ceramics, which allow for customization based on the specific requirements of the application. For example, seals made from Viton are suitable for aggressive chemicals, whereas those made from silicone may be used in food processing applications.mechanical shaft seal

Moreover, mechanical shaft seals contribute significantly to energy efficiency. By preventing leakage, they help maintain the intended pressure within a system, reducing the need for additional energy input to compensate for lost fluid. This not only lowers operational costs but also minimizes environmental impact, making mechanical shaft seals an integral part of sustainable industrial practices.

In various industries, such as automotive, aerospace, and manufacturing, the reliability of mechanical shaft seals can directly influence safety and performance. Regular maintenance and monitoring are essential to ensure the longevity of the seals. Over time, seals may wear due to extreme operational conditions, leading to potential failure. Implementing effective inspection procedures can help in early detection of seal degradation, thereby preventing unexpected downtime.

In conclusion, mechanical shaft seals are vital components in maintaining the efficiency and reliability of rotating equipment. Their ability to prevent leaks, withstand harsh conditions, and contribute to energy savings underscores their importance across multiple industries. As technology advances, ongoing innovations in materials and design will likely enhance the performance and longevity of these indispensable seals, driving further improvements in industrial efficiency and sustainability.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories