Main Pulley Oil Seal Importance and Maintenance Tips for Optimal Performance

Understanding the Importance of Main Pulley Oil Seals

Oil seals are essential components in various machinery, particularly in automotive and industrial applications. Among them, the main pulley oil seal plays a pivotal role in maintaining the efficiency and longevity of an engine or rotating machinery. This article delves into the functions, benefits, and maintenance of main pulley oil seals, providing a comprehensive understanding of why these seals are crucial.

What is a Main Pulley Oil Seal?

The main pulley oil seal, often referred to as the crankshaft oil seal in automobiles, is designed to prevent oil from leaking out of the engine. It is located at the front end of the crankshaft, where the pulley is mounted. This seal ensures that the lubricating oil is retained within the engine, thus maintaining optimal operation and preventing potential damage caused by oil spills.

Functions of Main Pulley Oil Seals

The primary function of the main pulley oil seal is to provide a barrier that contains the lubricating oil within the crankcase. This is vital for several reasons

1. Lubrication The engine needs adequate lubrication for smooth operation. The oil seal ensures that oil is not lost due to leakage, maintaining proper lubrication levels.

2. Protection Against Contamination The oil seal acts as a shield against dust, dirt, and other contaminants that can enter the engine. By preventing foreign particles from entering, the oil seal helps maintain the integrity of the engine oil.

3. Pressure Retention The seal is designed to withstand the high pressure generated within the engine. It ensures that the internal oil pressure remains stable, which is crucial for efficient lubrication.

Benefits of Using High-Quality Main Pulley Oil Seals

Investing in high-quality main pulley oil seals can yield numerous benefits

- Reduced Leakage High-quality seals provide a better fit and durability, minimizing the risk of oil leaks.

- Longer Engine Life By effectively containing the oil and protecting the engine from contamination, quality oil seals can significantly extend the lifespan of the engine

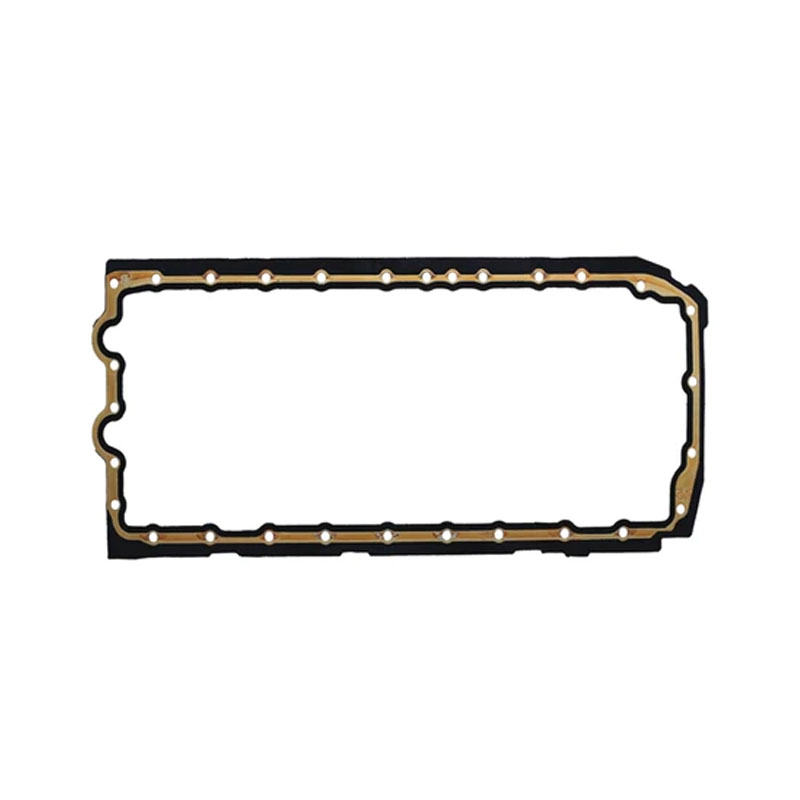

.main pulley oil seal

- Cost-Effective Maintenance While the initial cost of quality seals may be higher, they reduce the likelihood of frequent replacements and repairs, ultimately saving money in the long run.

Signs of a Faulty Main Pulley Oil Seal

Recognizing the signs of a failing oil seal is crucial for timely intervention. Common indicators include

- Oil Leaks The most obvious sign is the presence of oil spots under the vehicle or equipment.

- Engine Performance Issues If the engine shows signs of lubrication problems, such as increased friction or overheating, it may indicate an oil seal issue.

- Unusual Noises A failing seal can lead to improper oil levels, which may cause abnormal sounds in the engine due to insufficient lubrication.

Maintenance Tips

To ensure that the main pulley oil seal remains effective, regular maintenance is essential. Here are some tips

1. Regular Inspections Frequently check for oil leaks and examine the condition of the seal during routine maintenance.

2. Quality Oil Changes Use high-quality engine oil and change it as recommended to reduce the strain on the oil seal.

3. Professional Assistance If any issues are detected, consult a qualified mechanic for inspections and repairs.

Conclusion

The main pulley oil seal is a small yet critical component that plays a significant role in the efficient functioning of an engine or machinery. Understanding its importance, identifying potential problems early, and maintaining it properly can lead to enhanced performance and longevity of your engine. By prioritizing the maintenance of oil seals, you ensure a smoother, more reliable operation of your vehicle or equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories