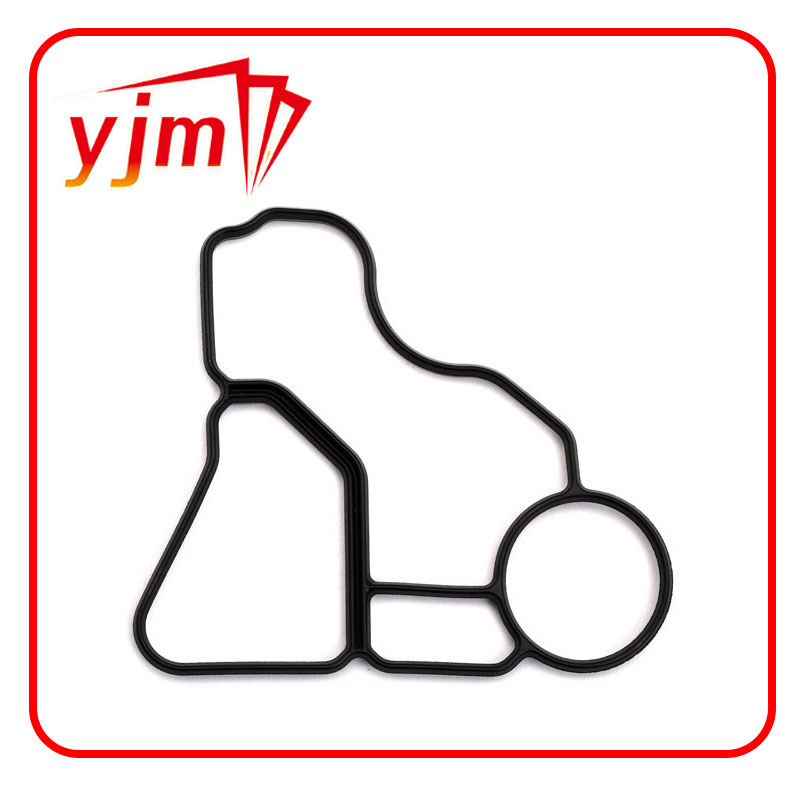

dorman oil drain plug

The authoritative discussion on M16 oil drain plugs often focuses on the benefits of magnetic versions. These plugs are particularly favored in high-performance vehicles or older engines as they attract and trap metal particles circulating in the oil, providing an additional layer of engine protection. However, it is crucial to consider the plug's magnetic strength and compatibility with the vehicle's oil pan material to avoid any potential issues. In terms of trustworthiness, selecting the right M16 oil drain plug underscores the importance of quality and sourcing from reputable manufacturers. Ensuring the product comes with certifications or positive reviews from trusted forums and communities is vital. This due diligence prevents the pitfalls of counterfeit or substandard components that could compromise engine integrity. Beyond component selection, regular inspection and maintenance of the oil drain plug itself are imperative. Checking for signs of wear, such as rounded edges or stripped threads, helps avert future problems. When replacement is necessary, investing in a new high-quality M16 oil drain plug ensures that oil changes continue to be clean, efficient, and safely conducted. In conclusion, while the M16 oil drain plug may seem like a minor aspect of vehicle maintenance, its importance cannot be underestimated. With the right approach—balancing practical experience with technical expertise and making informed decisions based on authoritative advice—vehicle owners and mechanics alike can trust that their engines are in safe hands. Prioritizing quality in such small yet significant automotive components is a testament to the commitment to vehicle longevity, underscoring both reliability and performance.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories