M14x1.5 Oil Drain Plug Specifications and Applications for Vehicles

Understanding the M14x1.5 Oil Drain Plug A Comprehensive Guide

When it comes to automotive maintenance, one of the essential components that often gets overlooked is the oil drain plug. Specifically, the M14x1.5 oil drain plug has gained attention for its application in various vehicles. This article delves into the significance of this component, its specifications, installation procedures, and some best practices for maintaining the oil drain plug, ensuring that your vehicle runs smoothly while preventing oil leaks and ensuring efficient oil changes.

What is an M14x1

.5 Oil Drain Plug?The designation M14x1.5 refers to the thread size and pitch of the drain plug. The M14 indicates a nominal diameter of 14 mm, while 1.5 refers to the thread pitch, meaning there are 1.5 mm between the threads. These specifications are crucial for ensuring a secure and leak-proof fit when the drain plug is installed on the oil pan of an engine.

Oil drain plugs play a vital role in any engine's performance and longevity. They serve as the point of entry for draining used engine oil while also sealing the oil pan to prevent leaks during the engine's operation. Given that oil is the lifeblood of an engine, maintaining a proper seal is essential to ensure that the engine is adequately lubricated and protected from wear and tear.

Importance of Proper Installation

Proper installation of the M14x1.5 oil drain plug is critical. An improperly installed plug can result in oil leaks, leading to insufficient lubrication, which can cause severe engine damage over time. To install the plug, ensure that the threads are clean and free from debris, and use a suitable torque wrench to tighten it to the manufacturer's specifications. This guarantees that the drain plug is neither over-tightened (which could strip the threads) nor too loose (which could lead to leaks).

Best Practices for Maintenance

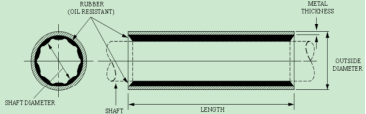

m14x1 5 oil drain plug

1. Regular Inspection Incorporate the inspection of the oil drain plug into your regular maintenance routine. Look for signs of wear, corrosion, or thread damage. If you notice any of these issues, it may be time to replace the plug.

2. Use of Gaskets or Washers To ensure a proper seal, many mechanics recommend using a new gasket or washer every time the oil is changed. This helps to maintain the integrity of the oil seal and prevents leaks.

3. Check Torque Specifications Each vehicle manufacturer provides specific torque specifications for oil drain plugs. Adhering to these guidelines will help prevent future problems and ensure the longevity of the oil pan and the drain plug.

4. Choose Quality Materials Not all oil drain plugs are created equal. Opt for high-quality materials such as aluminum or brass, which are less prone to corrosion and offer better performance over time.

5. Avoid Over-tightening While it may be tempting to ensure the plug is tight, over-tightening can lead to thread stripping or even cracking the oil pan. Follow the torque specifications provided by the vehicle manufacturer diligently.

Conclusion

In summary, the M14x1.5 oil drain plug is a small but essential component of your vehicle's engine system. By understanding its role and following best practices for installation and maintenance, you can help ensure that your engine remains healthy and operational for many miles to come. Regular checks, appropriate torque application, and the use of quality materials play significant roles in preventing leaks and prolonging the lifespan of your engine. With the right care, this little plug can have a big impact on your vehicle's performance and reliability.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories