M14 Aluminum Crush Washer for Effective Sealing and Maintenance Solutions

Understanding M14 Aluminum Crush Washers Essential Components for Automotive Applications

In the world of automotive engineering and maintenance, every component plays a significant role in the overall efficiency and durability of vehicles. Among these components, the M14 aluminum crush washer is a seemingly small but crucial part that ensures leak-proof seals in various applications, particularly in the engine and transmission systems.

What is an M14 Aluminum Crush Washer?

An M14 aluminum crush washer is a circular, disc-like component specifically designed to create a tight seal when installed between two surfaces, typically a bolt and the component it secures. Its design helps compensate for any imperfections in surface finishes, thereby preventing leaks of fluids such as oil, fuel, and other critical automotive fluids. The M14 designation refers to the metric measurement of the washer's inner diameter, ensuring compatibility with M14-sized bolts.

Importance in Automotive Applications

1. Seal Integrity The primary function of a crush washer is to provide an effective barrier against leaks. When a bolt is tightened, the crush washer deforms slightly, filling in any gaps between the surfaces and creating a secure seal. This is particularly important in high-pressure areas of the engine where hydraulic fluids are present.

2. Material Properties Aluminum is favored for crush washers due to its lightweight, corrosion resistance, and malleability. The malleability of aluminum allows the washer to compress under pressure without cracking, which is essential for maintaining a reliable seal over time.

3. Cost-Effectiveness Using aluminum crush washers is a cost-effective approach for manufacturers and mechanics alike. They are relatively inexpensive, and their ability to prevent leaks can save considerable amounts of money in fluid replacement and potential repairs caused by leaks.

Installation & Maintenance

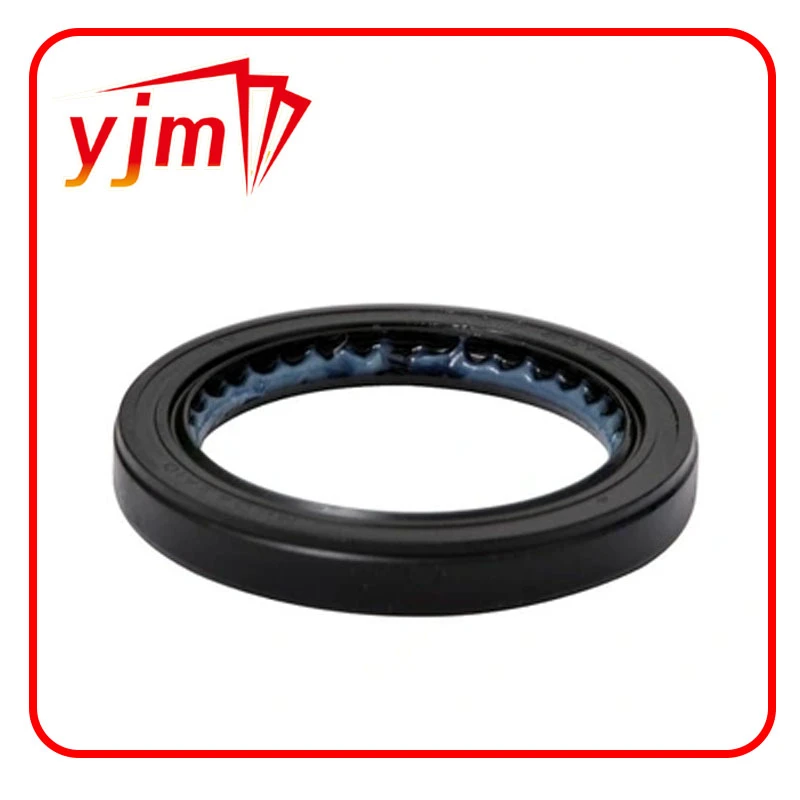

m14 aluminum crush washer

Proper installation of M14 aluminum crush washers is vital to ensure they function correctly. Here are some essential tips for installation

- Surface Preparation Before installing the washer, ensure that both mating surfaces are clean and free of debris. Any dirt or old gasket material can compromise the seal.

- Correct Torque Specifications Always adhere to the manufacturer’s torque specifications when tightening the bolt. Over-tightening can lead to damage to the washer, while under-tightening might result in leaks.

- Replacement Crush washers are designed for single use. After being compressed during installation, they lose their ability to form an effective seal and should be replaced whenever a bolt is removed.

Common Applications

M14 aluminum crush washers are commonly found in various automotive applications, including but not limited to

- Oil Drain Pans Ensuring that engine oil does not leak during operation. - Fuel Systems Sealing connections in fuel lines to prevent leaks that could lead to severe safety hazards. - Transmission Components Creating reliable seals in transmission fluid lines and case fittings, ensuring smooth operation.

Conclusion

While often overlooked, the M14 aluminum crush washer is an integral part of maintaining the integrity and efficiency of automotive systems. Its unique design, combined with the properties of aluminum, allows for effective sealing in a variety of environments, particularly where high pressure and temperature variations are present. For anyone involved in automotive repair or manufacturing, understanding and utilizing the correct type of crush washer is crucial for ensuring that vehicles perform optimally and endure the test of time. By prioritizing the right components, mechanics can contribute significantly to vehicle safety and longevity, making M14 aluminum crush washers a small yet mighty player in the automotive industry.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories