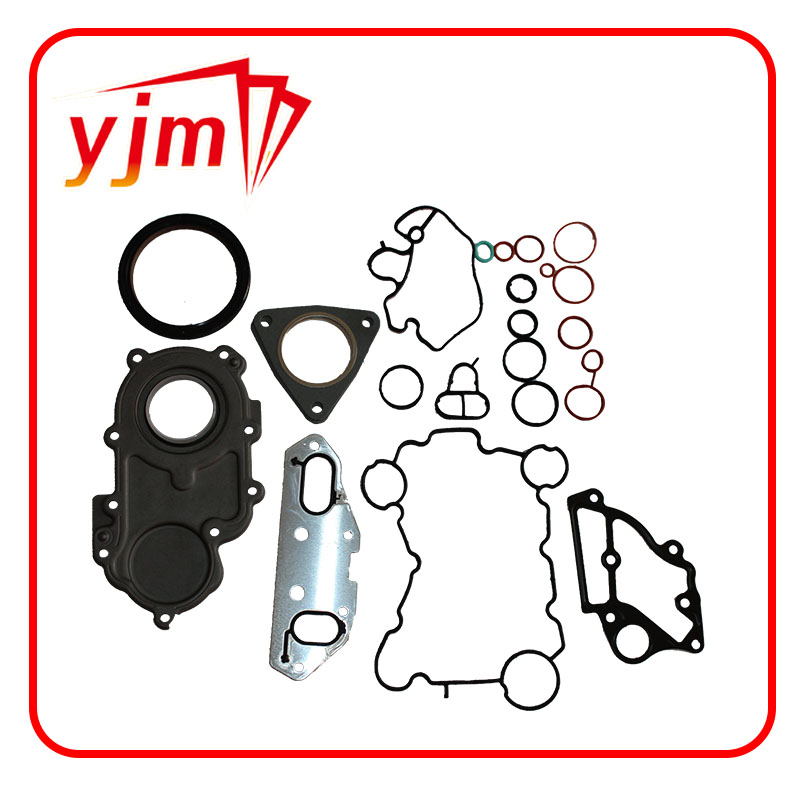

lip seal ring

The Importance of Lip Seal Rings in Modern Engineering

In the realm of mechanical engineering and manufacturing, sealing solutions play a critical role in maintaining the integrity and functionality of various systems. Among the numerous sealing technologies available, lip seal rings stand out due to their unique design and versatile application. These seals, often referred to simply as lip seals, serve a crucial function in a wide array of industries, from automotive to aerospace, and even in household appliances.

Understanding Lip Seal Rings

Lip seal rings are typically composed of elastomeric materials, which allow them to create a tighter fit against the surface they protect. The primary design feature of a lip seal is its lip, a flexible extension that interacts with the shaft or housing it is sealing. This lip adapts to the surface’s contours, providing an effective barrier against contaminants and retaining lubricants.

The effectiveness of lip seal rings lies in their ability to accommodate various shaft diameters and speeds while maintaining their sealing capabilities. They are utilized in numerous applications, including rotating shafts, hydraulic cylinders, and gearboxes.

Advantages of Lip Seal Rings

One of the prominent advantages of lip seal rings is their simplicity and effectiveness

. With a straightforward installation process, they can be put in place quickly, reducing downtime during maintenance and assembly. Additionally, due to their flexible nature, lip seals can accommodate thermal expansion and contraction, making them ideal for dynamic applications where temperatures fluctuate.Moreover, lip seal rings offer exceptional performance against both liquid and solid contaminants, which is vital in environments where dust, dirt, and other particulates may pose a risk. Their design minimizes friction between the seal and the shaft, which in turn leads to a longer lifespan for both the seal and the machinery it protects.

lip seal ring

Material Choices and Customization

The material selection for lip seals plays a significant role in their performance and durability. Common materials include nitrile rubber (NBR), fluorocarbon rubber (FKM), and silicone, each providing different advantages based on factors such as temperature resistance, chemical exposure, and mechanical load. This variety allows engineers to choose the appropriate seal for the specific conditions of their application.

Furthermore, many manufacturers offer customization options for lip seals. This can include variations in size, shape, material, and even the design of the sealing lip itself, allowing for tailored solutions that fit unique engineering requirements.

Challenges and Limitations

Despite their numerous advantages, lip seal rings are not without challenges. Over time and with constant movement, they can experience wear, leading to leakage. High operating temperatures or exposure to aggressive chemicals can also degrade the seal material, resulting in failure. To mitigate these risks, regular maintenance and proper installation practices are essential.

Final Thoughts

In conclusion, lip seal rings are an indispensable component in the modern engineering landscape. Their ability to provide efficient sealing solutions for a wide range of applications ensures their presence in various industries. With ongoing advancements in materials and design, lip seals are evolving to meet the demands of increasingly sophisticated machinery and environments. Engineers and manufacturers must continue to prioritize the selection and maintenance of these seals to ensure optimal performance and longevity in their systems. As technology progresses, the role of lip seal rings will undoubtedly grow, solidifying their position as a cornerstone of mechanical design in the years to come.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories