lip oil seal types

Understanding Lip Oil Seal Types

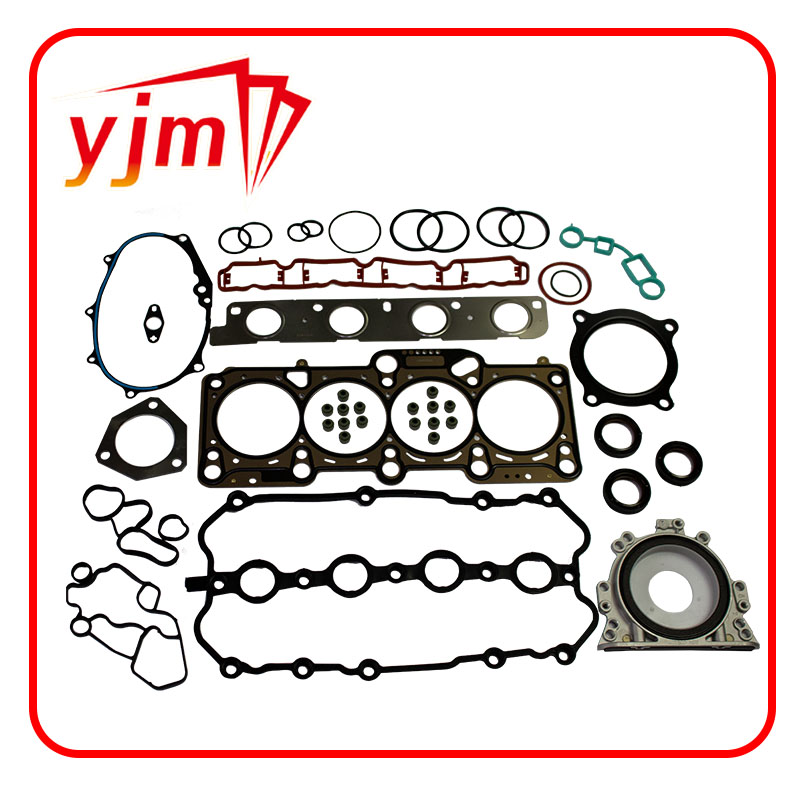

In the domain of mechanical engineering and maintenance, oil seals play a crucial role in ensuring the effective functioning of various machinery. Among these, lip oil seals are particularly important due to their ability to prevent the leakage of oil and other lubricants from rotating or moving components. This article delves into the different types of lip oil seals and their applications.

Types of Lip Oil Seals

1. Single-Lip Oil Seals These are the most common type of lip seals, featuring a single lip that contacts the shaft. They are ideal for environments where only one direction of leakage needs to be controlled. Single-lip seals are widely used in automotive applications, such as engines and transmissions, where they play a vital role in maintaining oil levels and preventing contamination.

2. Double-Lip Oil Seals As the name suggests, these seals feature two lips – an inner and an outer lip. This design provides an added layer of protection against leaks, making them suitable for more demanding environments. Double-lip seals are often used in heavy machinery and industrial applications where the risk of external contamination or oil loss is higher.

lip oil seal types

3. Spring-Loaded Lip Oil Seals These seals incorporate a spring mechanism which helps to maintain contact between the lip and the shaft, regardless of wear or thermal expansion. This design enhances sealing capability and extends the operational lifespan of the seals. Spring-loaded lip oil seals are frequently used in situations where there are variations in shaft speed or pressure.

4. Heavy-Duty Oil Seals Designed to withstand high pressure and harsh operating conditions, heavy-duty oil seals come with reinforced materials to enhance durability. They are typically used in construction equipment, agricultural machinery, and other demanding industrial applications where conventional seals may not suffice.

5. Custom Oil Seals In certain applications, standard seals may not provide the required fit or function. Custom oil seals can be manufactured to meet specific dimensional and material requirements, ensuring optimal performance in unique environments.

Conclusion

Selecting the appropriate type of lip oil seal is critical for the reliability and efficiency of machinery. Understanding the differences between single-lip, double-lip, spring-loaded, heavy-duty, and custom oil seals can help engineers and maintenance professionals choose the right solution for their specific needs. Proper installation and regular maintenance of these seals will not only reduce the risk of oil leakage but also prolong the life of the machinery, leading to cost savings and improved operational efficiency.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories