Understanding the Functionality and Applications of Linear Shaft Seals in Machinery

Understanding Linear Shaft Seals An Essential Component for Machinery

Linear shaft seals play a crucial role in the functionality and longevity of various machinery and equipment. These seals are specifically designed to prevent the leakage of fluids along linear shafts, which are commonly found in hydraulic systems, pneumatic systems, and rotating equipment. As industries increasingly rely on automated and high-performance systems, understanding the importance and functionality of linear shaft seals has become essential for engineers and manufacturers alike.

What Are Linear Shaft Seals?

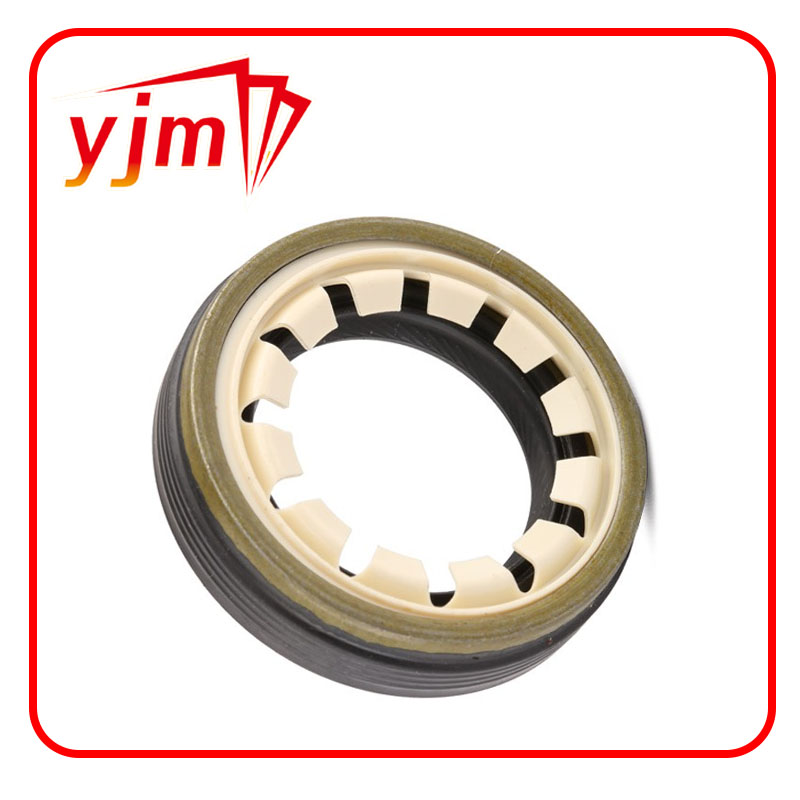

Linear shaft seals are engineered components that create a barrier between the moving shaft and the housing, effectively preventing fluid leakage. They are made from a combination of materials such as rubber, elastomers, and thermoplastics, which provide flexibility and resilience. The design typically consists of a sealing element that fits snugly around the shaft, creating a tight seal that minimizes the risk of fluid loss. These seals are particularly important in applications where maintaining pressure and preventing contamination are critical.

Types of Linear Shaft Seals

There are various types of linear shaft seals, each tailored to meet specific operational requirements. Some of the most common types include

1. Lip Seals These seals utilize a flexible lip that can compress against the shaft, creating a tight seal. Lip seals are often used in applications where low friction is paramount, as they allow the shaft to move freely while preventing leaks.

2. U-Cup Seals Shaped like a U, these seals are effective in high-pressure applications. They provide excellent sealing capabilities and can handle substantial axial loads, making them suitable for hydraulic and pneumatic systems.

3. O-Ring Seals O-rings are circular seals that fit into grooves and create a seal when compressed. They are versatile and can be used in various applications, although their effectiveness depends on the correct sizing and the material used.

linear shaft seal

4. V-Ring Seals These seals have a unique design that allows them to work well against rotating shafts. V-rings provide trouble-free sealing and are often used in low-pressure applications.

Applications of Linear Shaft Seals

Linear shaft seals are utilized across multiple industries, including automotive, aerospace, manufacturing, and construction. In the automotive sector, they are found in engines, transmissions, and axles, where they help maintain oil pressure and prevent leaks. In aerospace, linear shaft seals are essential for ensuring the reliability of hydraulic systems in aircraft components.

Manufacturing equipment often relies on linear shaft seals to maintain the integrity of hydraulic systems, while construction machinery benefits from their ability to seal hydraulic cylinders and prevent fluid loss in harsh working conditions. Given their versatility, these seals are integral to efficient machine operation and overall system performance.

Importance of Proper Maintenance

While linear shaft seals are built to withstand significant wear and tear, their longevity is greatly influenced by proper maintenance practices. Regular inspections are necessary to identify signs of wear, such as cracking or hardening, which can compromise their sealing capabilities. Additionally, ensuring that the shaft is smooth and free from debris will enhance the effectiveness of the seals.

Cleaning the sealing areas and promptly addressing any leaks or failures can prevent costly downtime and repairs. When replacing linear shaft seals, selecting the appropriate type and material is crucial, as this will significantly impact the performance and lifespan of the machinery.

Conclusion

In summary, linear shaft seals are essential components that ensure the effective functioning of various types of machinery. Their ability to prevent fluid leakage plays a critical role in maintaining pressure, reducing contamination, and enhancing the overall efficiency of systems. As technology advances and machinery becomes more complex, the role of linear shaft seals is likely to become even more significant, making it crucial for industry professionals to understand their applications and maintenance. By prioritizing quality and regular maintenance, businesses can maximize performance and extend the life of their equipment.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories