Innovative Magnetic Oil Seal Design for Enhanced Performance and Durability

Understanding Magnet Oil Seals An Essential Component in Machinery

Magnet oil seals are an integral part of various mechanical systems, playing a crucial role in ensuring the efficiency and longevity of machinery. These seals are designed to prevent the leakage of lubricants and other fluids while simultaneously protecting the internal components of a system from contaminants. By examining the functionality, applications, and benefits of magnet oil seals, we can appreciate their significance in modern engineering.

What is a Magnet Oil Seal?

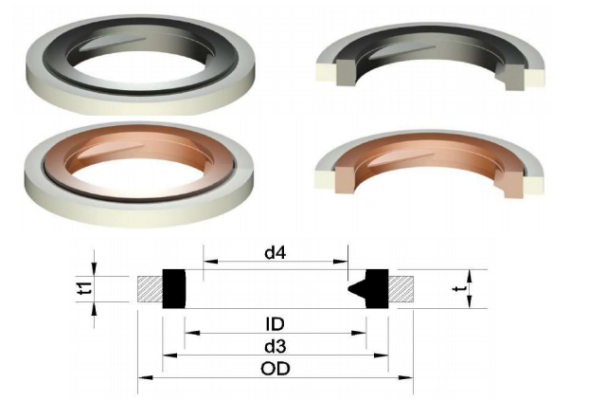

A magnet oil seal typically consists of several components, including a metal casing, rubber or elastomeric sealing surfaces, and a magnetic element. The primary function of the seal is to create a barrier between the internal workings of machinery and the external environment. The magnetic element helps to maintain a secure fit, allowing the seal to adapt to vibrations and changes in temperature. This adaptability is essential as it ensures that the oil seal maintains its integrity over time, preventing fluid loss and intrusion of debris.

Functionality and Design

The design of magnet oil seals varies based on the specific application and operational conditions. However, there are common features that define their functionality. The magnetic element enhances the seal's ability to stay in place, providing resistance to pressure and motion. This is particularly important in high-impact environments where traditional sealing methods might fail due to vibration or thermal expansion.

Another critical characteristic of magnet oil seals is their ability to accommodate movement. Many mechanical systems experience oscillation or rotational movement, and a traditional static seal may not perform adequately in these conditions. Magnet oil seals, with their flexible materials and magnetic holding capability, can adjust to these changes without compromising sealing effectiveness.

Applications of Magnet Oil Seals

magnet oil seal

Magnet oil seals are used across various industries, including automotive, aerospace, manufacturing, and oil and gas. In the automotive sector, these seals are vital in engines and transmission systems, where they help retain oil and lubricants, ensuring smooth operation and preventing wear and tear on moving parts. In aerospace applications, the reliability of oil seals is critical given the extreme conditions faced at high altitudes and harsh environments.

In manufacturing machinery, magnet oil seals are integral to hydraulic systems and heavy equipment. They protect sensitive hydraulic fluids from contamination while providing a robust seal against pressure fluctuations. The oil and gas industry also relies on magnet oil seals for drilling equipment and pipeline systems, where preventing leaks and maintaining pressure is paramount.

Advantages of Magnet Oil Seals

One of the significant advantages of using magnet oil seals is their durability. The robust materials used in their design ensure they can withstand harsh conditions, leading to longer service life compared to conventional seals. Additionally, the ability to maintain a tight seal reduces the frequency of maintenance checks and replacements, ultimately saving time and cost for operators.

Moreover, the magnetic aspect of these seals allows for easy installation and adjustment. The self-aligning feature helps technicians position the seal correctly without the need for complex tools or fixtures. This ease of installation enhances efficiency in manufacturing settings, where time is of the essence.

Conclusion

In summary, magnet oil seals are pivotal in modern mechanical systems, providing essential sealing capabilities that enhance the performance and durability of machinery. Their unique design, capable of withstanding various environmental challenges, makes them a preferred choice in many industries. As technology continues to evolve, the role of magnet oil seals is expected to expand further, contributing to more efficient and reliable machinery designs around the globe.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories