Understanding the Importance of Industrial Oil Seals in Machinery Performance

Understanding Industrial Oil Seals Their Importance and Applications

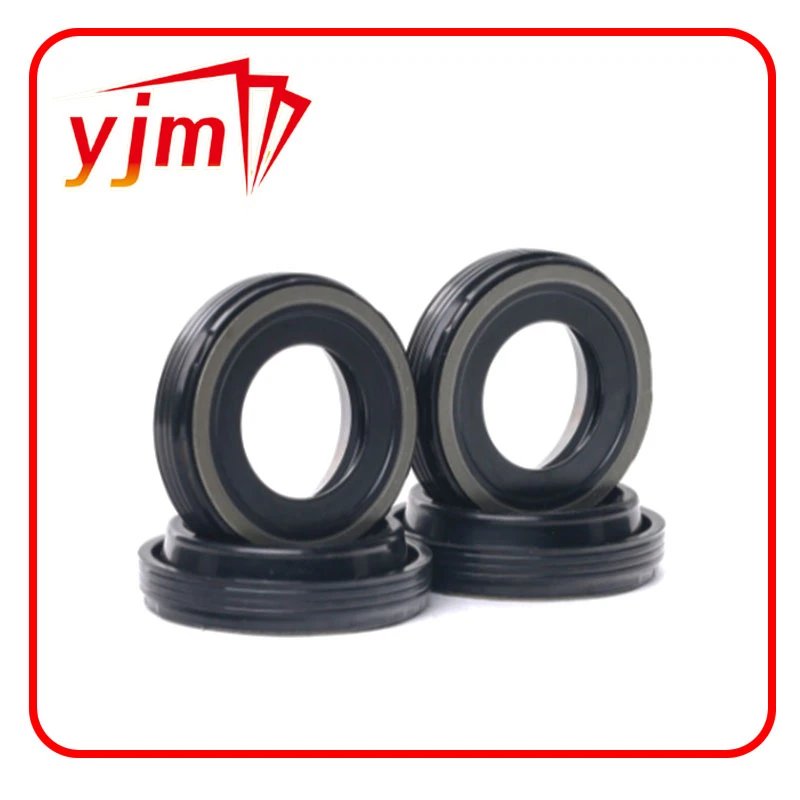

Industrial oil seals play a critical role in several mechanical systems across various industries. These seals are designed to prevent the leakage of lubricants, such as oils and greases, while also keeping contaminants out of the machinery. This dual function is vital for ensuring the longevity and efficiency of mechanical equipment in manufacturing, automotive, aerospace, and many other sectors.

At their core, oil seals consist of a flexible elastomeric material such as rubber, a metal casing, and a spring. The flexible material provides a tight seal against the rotating shaft, while the metal casing adds structural integrity. The spring, typically positioned on the inner side of the seal, exerts pressure against the shaft, ensuring that the seal maintains contact despite minor axial movements or shaft wear. This design contributes to minimizing friction and optimizing performance, thus extending the life of both the components being sealed and the seal itself.

Importance of Industrial Oil Seals

The significance of oil seals in industrial settings cannot be overstated. First and foremost, they help prevent oil leaks, which can lead to costly maintenance, environmental hazards, and potential safety risks. Oil leakage can affect not only the functionality of the machine but also create a mess in the working environment, leading to slip hazards and additional cleanup costs.

Furthermore, oil seals protect against the ingress of dirt, dust, water, and other contaminants that could compromise the lubrication system. Contaminated oil can lead to accelerated wear and tear on moving parts, increasing friction and temperature, which ultimately results in premature failure of the equipment. By maintaining a clean and secure environment around the lubricated areas, oil seals contribute to the overall efficiency and reliability of machinery.

Applications Across Industries

Industrial oil seals are ubiquitous and find applications in a wide range of industries. In the automotive sector, oil seals are crucial components for engines, transmission systems, and differentials. They help maintain the optimal performance of vehicles by preventing fluid leaks and safeguarding internal components from contaminants.

industrial oil seals

In manufacturing, machines like pumps, compressors, and gearboxes rely heavily on oil seals to function efficiently. These seals ensure that the lubricants do not escape, which is essential for minimizing wear on moving parts and maintaining energy efficiency.

The aerospace industry also utilizes oil seals in various applications, including landing gear systems and hydraulic actuators. The high-performance requirements in this sector demand seals that can withstand extreme temperatures, pressures, and environmental conditions, making the choice of quality oil seals critical.

Choosing the Right Oil Seal

Selecting the appropriate oil seal for an application involves considering several factors, including the type of lubricant being used, the temperature range, pressure conditions, and the specific contaminants present in the environment. The material choice is vital, as different elastomers possess varying resistance to chemicals, heat, and wear.

Moreover, ensuring that the seal is correctly installed and regularly maintained is essential for optimal performance. Regular inspections can help identify wear and tear, allowing for timely replacements before significant issues arise.

Conclusion

In conclusion, industrial oil seals are fundamental components that ensure the smooth operation of various machines across multiple sectors. Their ability to prevent leaks and protect against contaminants directly influences equipment performance and lifespan. Understanding their importance and choosing the right seals can lead to enhanced efficiency, reduced maintenance costs, and a safer operational environment. By prioritizing these components, industries can significantly boost productivity and reliability in their mechanical systems.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories