hydrogenated nitrile o ring

Hydrogenated Nitrile O-Rings Advancements and Applications

In the realm of industrial applications, seals and gaskets play a crucial role in ensuring the efficient functioning of machinery and equipment. Among the various sealing materials available, hydrogenated nitrile O-rings have gained considerable attention due to their superior properties and versatility. This article delves into the characteristics, production, and applications of hydrogenated nitrile O-rings, highlighting their importance in modern engineering.

Hydrogenated Nitrile O-Rings Advancements and Applications

One of the standout features of hydrogenated nitrile O-rings is their exceptional resistance to oil and fuel. This property makes them particularly valuable in the automotive and aerospace industries, where components are frequently exposed to petroleum-based products. Furthermore, HNBR O-rings exhibit excellent mechanical strength, ensuring they can withstand high-pressure conditions without failure. Their ability to retain flexibility over a broad temperature range, usually from -40°C to 150°C, adds to their usability across various applications.

hydrogenated nitrile o ring

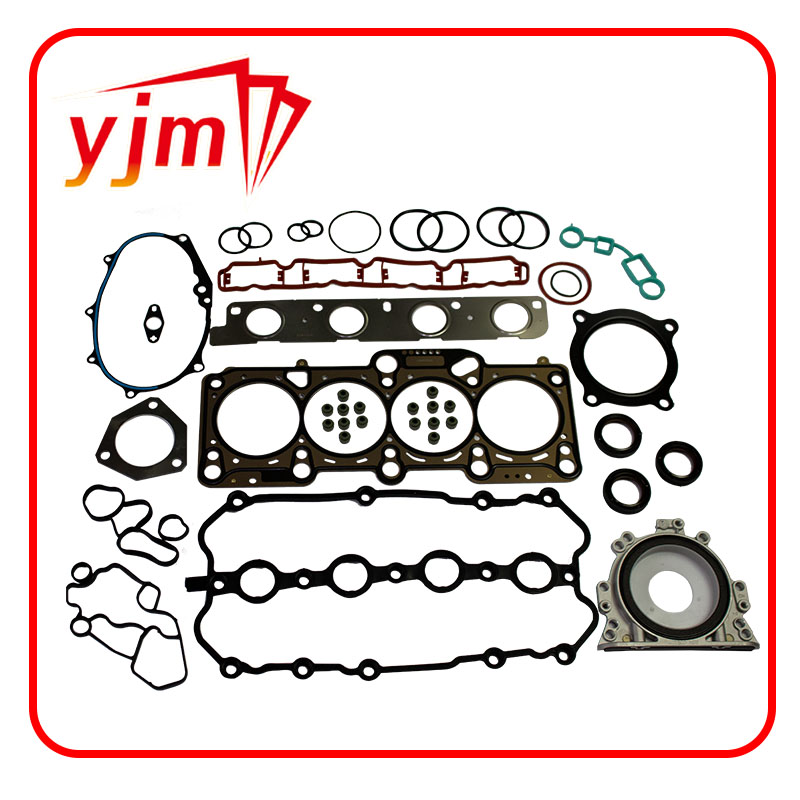

The manufacturing process of hydrogenated nitrile O-rings involves the careful blending of raw HNBR compounds, along with fillers, plasticizers, and curing agents. This mixture is then shaped into O-rings through molding or extrusion techniques. The production process may include additional steps such as vulcanization, which enhances the cross-linking of the polymer chains, thereby improving the O-ring’s durability and performance.

In terms of applications, hydrogenated nitrile O-rings are extensively used in sectors ranging from automotive to pharmaceuticals. In the automotive industry, they are found in fuel systems, hydraulic systems, and engine components, where they ensure leak-free performance. In aerospace, their resilience to extreme temperatures and pressures makes them ideal for sealing applications in engines and fuel systems. Moreover, the oil and gas industry benefits from HNBR O-rings, as they safeguard critical equipment from corrosive substances and high-pressure conditions.

The compatibility of hydrogenated nitrile O-rings with various chemical substances, including acids, alkalis, and lubricants, further broadens their usability. This adaptability extends to applications in the food and beverage industry as well, where ensuring the safety and integrity of products is paramount. As regulations concerning food safety continue to tighten, the demand for reliable sealing solutions like HNBR O-rings is expected to increase.

In conclusion, hydrogenated nitrile O-rings represent a significant advancement in sealing technology. Their remarkable chemical resistance, thermal stability, and flexibility make them indispensable components across numerous industries. As technology evolves, the continued refinement and application of hydrogenated nitrile materials will likely lead to even greater innovations in sealing solutions, ensuring safety and efficiency in diverse operational contexts. The future of hydrogenated nitrile O-rings is bright, with vast potential for enhancing equipment performance in increasingly demanding environments.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories