Hydraulic Sealing Solutions for Enhanced Bonding Performance and Reliability

Understanding Hydraulic Bonded Seals A Key Component in Fluid Control Systems

Hydraulic systems are indispensable in various industries, including manufacturing, automotive, aerospace, and construction. At the core of these systems lies a critical component known as the hydraulic bonded seal. This article explores the function, applications, advantages, and types of hydraulic bonded seals, along with their significance in modern engineering.

What is a Hydraulic Bonded Seal?

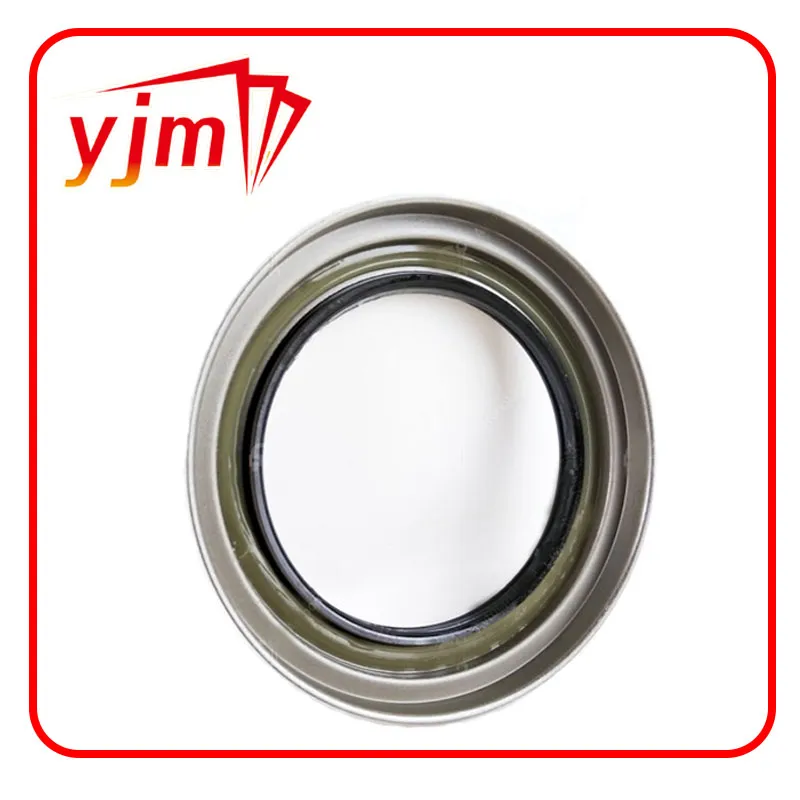

A hydraulic bonded seal is a sealing solution designed to prevent fluid leakage in hydraulic applications. It is typically composed of elastomeric materials, such as rubber, bonded to a metal backing. This design promotes a strong interface between the seal and the mating surfaces, ensuring a reliable seal that can withstand the high pressures and temperatures often found in hydraulic systems.

Applications of Hydraulic Bonded Seals

Hydraulic bonded seals are widely used in various applications, particularly in equipment that operates under high pressure. Some common applications include

1. Automotive In vehicle systems such as brake systems and hydraulic actuators, bonded seals play a critical role in preventing fluid leaks, enhancing safety and performance.

2. Heavy Machinery Construction equipment, such as excavators and bulldozers, utilize bonded seals to ensure that hydraulic lines do not fail under load, thereby maintaining operational efficiency.

3. Aerospace Hydraulic systems in aircraft require seals that can withstand extreme conditions. Bonded seals ensure reliable performance and safety in aircraft operations.

4. Industrial Equipment In manufacturing plants, hydraulic systems powered by bonded seals help in material handling, press operations, and robotic automation.

Advantages of Hydraulic Bonded Seals

Hydraulic bonded seals offer several key advantages that enhance their performance in demanding applications

1. Pressure Resistance These seals can endure high pressures, making them suitable for hydraulic systems that operate under severe conditions.

hydraulic bonded seal

2. Durability The bonding of elastomeric materials to metal significantly increases the seal's lifespan, reducing the need for frequent replacements.

3. Enhanced Sealing Performance The bonded structure provides a robust sealing surface that reduces the likelihood of fluid leakage, thereby improving operational efficiency.

4. Versatility Available in various shapes and sizes, bonded seals can be customized to fit specific applications, making them versatile for different systems.

5. Cost-Effectiveness While the initial cost may be higher than traditional seals, the longevity and reduced maintenance needs of hydraulic bonded seals lead to overall cost savings.

Types of Hydraulic Bonded Seals

Hydraulic bonded seals come in several types, each suited for different functionalities

1. O-rings Commonly used in cases where a circular seal is required, O-rings provide reliable sealing and can be used in a variety of applications.

2. Flat seals These are used in applications where a larger sealing area is needed. Flat bonded seals are effective in preventing fluid leakage between flat surfaces.

3. Cylindrical seals Designed for use in rotating applications, cylindrical seals provide a secure seal even under dynamic conditions.

4. Custom seals For specialized applications, custom hydraulic bonded seals can be developed to meet specific design requirements.

Conclusion

In summary, hydraulic bonded seals are crucial components in the functionality and reliability of hydraulic systems across various industries. Their ability to withstand high pressure and their durability make them a preferred choice for fluid control applications. As technology continues to advance, the development of new materials and bonding techniques promises to enhance the performance of these seals further. Understanding and implementing hydraulic bonded seals can lead to improved operational efficiency, safety, and cost-effectiveness in hydraulic applications. As industries evolve, the importance of such reliable sealing solutions will only continue to grow.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories