Exploring the Benefits and Applications of Hydraulic Bonded Seals in Modern Engineering

Understanding Hydraulic Bonded Seals A Comprehensive Overview

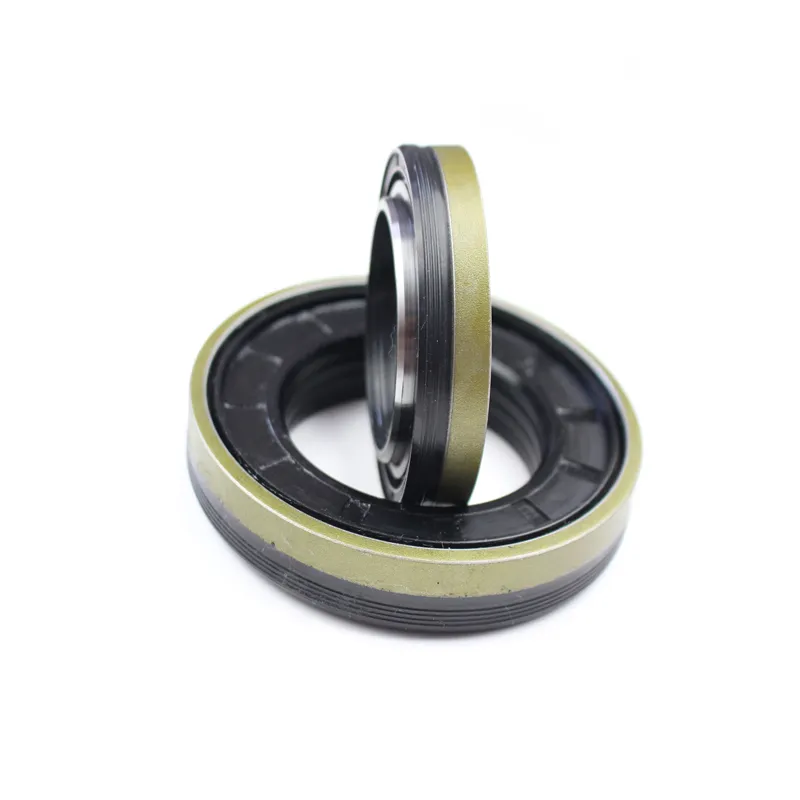

Hydraulic bonded seals are essential components in various industrial applications, providing reliable leakage prevention and enhancing the durability of critical systems. These seals are designed to withstand high pressures, temperatures, and demanding operating conditions, making them indispensable in sectors like automotive, aerospace, and manufacturing.

At the core of hydraulic bonded seals is the principle of bonding different materials to form a robust sealing solution. Typically composed of a elastomeric material, such as rubber, these seals are often bonded to metal components through specialized adhesives. This combination ensures a tight fit and prevents fluid leakage, which can be detrimental to the performance and safety of hydraulic systems.

The effective performance of hydraulic bonded seals hinges on several key factors, including the choice of material, the bonding process, and the sealing application

. For instance, the elastomer must be compatible with the fluids it will encounter, whether hydraulic oil, water, or other chemicals. Common materials include nitrile rubber (NBR), fluorocarbon (FKM), and silicone, each chosen for their unique properties, such as heat resistance or chemical compatibility.hydraulic bonded seal

The bonding process itself is critical; it must ensure that the seal maintains its integrity under varying pressures and temperatures. Advanced bonding techniques, such as chemical bonding or mechanical interlocking, are employed to achieve a strong and durable seal. The selection of adhesive plays a vital role as well, because it must be capable of withstanding the operational environment while ensuring optimal adhesion between dissimilar materials.

One of the significant advantages of hydraulic bonded seals is their ability to reduce maintenance costs. By providing effective sealing solutions, they minimize the risk of leaks, which can lead to fluid loss, equipment downtime, and increased operational costs. Furthermore, their durability translates into longer service life, which is particularly beneficial in applications where reliability is paramount.

Hydraulic bonded seals are also critical in ensuring safety in various applications. In the automotive sector, for example, they help prevent fluid leaks that can cause contamination or hazardous situations. Similarly, in aerospace, maintaining a sealed environment is essential for the reliability of hydraulic systems that control vital functions of the aircraft.

In conclusion, hydraulic bonded seals play a pivotal role in enhancing the performance and safety of hydraulic systems across various industries. By combining different materials through advanced bonding techniques, they provide an effective solution to prevent leaks and extend the service life of components. As industries continue to evolve and demand greater efficiency and reliability, the significance of hydraulic bonded seals will undoubtedly increase.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories