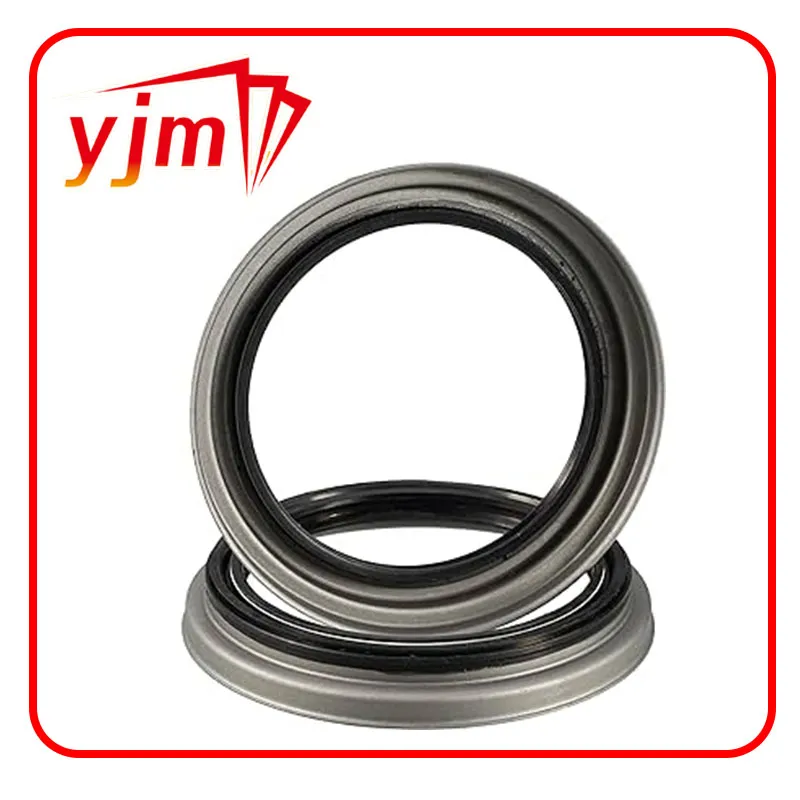

hta oil seal

HTA Oil Seal An Essential Component for Automotive and Industrial Applications

In today’s world, where automobiles and machinery play a crucial role in daily operations, the importance of reliable components cannot be overstated. One such critical component is the oil seal, particularly the HTA oil seal, which has gained attention for its durability and efficiency in preventing leaks and contamination.

What is an Oil Seal?

An oil seal, as the name suggests, is designed to seal the oil within various moving parts of machinery, engine compartments, and other mechanical assemblies. It ensures that lubricating oil remains enclosed, significantly reducing the risk of leaks that could lead to equipment failure or reduced efficiency. Oil seals are critical in applications such as engine crankshafts, gearbox assemblies, and hydraulic systems.

Overview of HTA Oil Seal

The HTA oil seal is a specific type of oil seal that is engineered to provide maximum protection against fluid leakage and contamination. It is made from high-quality materials that can withstand extreme temperatures, pressure, and harsh operating environments. The design integrity of HTA oil seals ensures a tight fit, which is necessary for the effective sealing of oils and lubricants used in mechanical systems.

Benefits of HTA Oil Seals

1. Durability and Longevity One of the most significant advantages of the HTA oil seal is its durability. Made from robust materials like rubber or thermoplastic elastomers, these seals can endure wear and tear better than standard seals. This durability translates to longer replacement intervals, reducing maintenance costs for vehicle and machinery owners.

2. Leak Prevention HTA oil seals are crafted to minimize the chance of leaks. This functionality is crucial in automotive applications where oil leaks can lead to engine damage or contamination of other components, resulting in costly repairs.

hta oil seal

3. Resistance to Environmental Factors Whether subjected to overheating, chemicals, or other harsh conditions, HTA oil seals maintain their integrity. Their resistance to environmental factors ensures that they continue to perform effectively regardless of the operating environment.

4. Improved Performance By ensuring that lubricants do not leak out and contaminants do not enter the system, HTA oil seals contribute to the overall efficiency of machinery. Proper lubrication is essential for minimizing friction and wear, thus enhancing the performance and lifespan of mechanical components.

Applications of HTA Oil Seals

HTA oil seals are widely used in various applications, including automotive, aerospace, industrial machinery, and home appliances. In the automotive sector, you can find these seals in engines, transmissions, and differential systems. They are equally essential in industrial machinery, where they prevent oil leaks in hydraulic systems, pumps, and gearboxes.

Choosing the Right HTA Oil Seal

When selecting an HTA oil seal, it is important to consider several factors, including the operating environment, the type of fluid being sealed, and the specific application. Proper installation is also crucial to ensure optimal performance; even the highest quality seal can fail if not installed correctly.

Conclusion

In conclusion, HTA oil seals represent a vital component in the machinery and automotive industry, ensuring effective sealing of lubricants and preventing contamination. Their durability, resistance to environmental factors, and role in enhancing mechanical performance make them an indispensable choice for many applications. As technology continues to advance, the design and manufacturing processes of oil seals like the HTA variant will likely evolve, further improving their efficiency and reliability. Investing in high-quality oil seals is, therefore, a wise decision for anyone looking to minimize maintenance costs and enhance the performance of their machinery or vehicle.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories