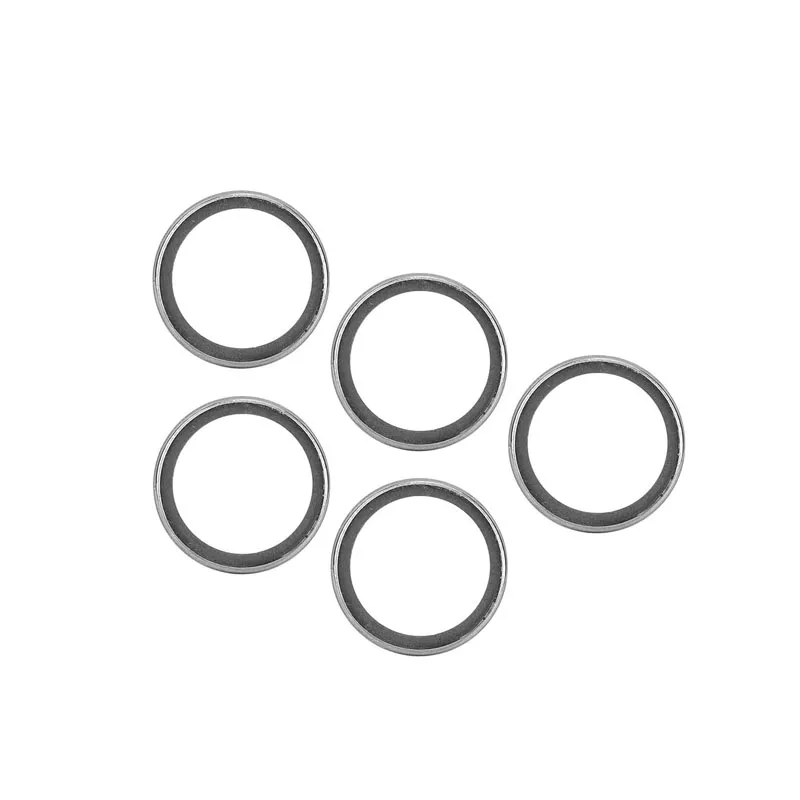

hta oil seal

Understanding HTA Oil Seals Essential Components for Effective Machinery

Oil seals, often referred to as shaft seals or rotary seals, are crucial components in various machinery and automotive applications. Among these, HTA (High Temperature and Abrasion) oil seals play a specialized role, especially in environments where high temperatures and particulate contaminants are prevalent. This article aims to explore the importance, functionality, and applications of HTA oil seals in machinery.

What are HTA Oil Seals?

HTA oil seals are designed to prevent the leakage of lubricants while simultaneously keeping harmful contaminants out of machinery. They are typically made from advanced materials that can withstand extreme temperatures and harsh operating conditions. The key features of HTA oil seals include their durability, flexibility, and resistance to wear and tear. These seals are engineered to meet the demanding requirements of heavy-duty applications, ensuring longevity and reliability.

Functions of HTA Oil Seals

HTA oil seals serve several essential functions in machinery

1. Leak Prevention The primary function of any oil seal, including HTA seals, is to prevent the escape of oil or lubricants from machinery. This is critical for maintaining the efficiency and performance of engines and other mechanical components.

2. Contaminant Exclusion HTA oil seals also act as barriers to dirt, dust, water, and other contaminants. This is particularly important in industrial settings or high-traffic environments where machinery is exposed to various hazards. By keeping such particles out, HTA seals prolong the lifespan of the equipment.

3. Temperature Resilience Built to withstand high temperatures, HTA oil seals remain effective even in extreme conditions. This aspect is vital in applications like automotive engines and industrial machinery, where heat can lead to seal degradation and eventual failure.

hta oil seal

4. Vibration Absorption In machinery that experiences a lot of movement or vibration, HTA oil seals help to absorb shock and reduce wear between moving parts. This function contributes to smoother operation and less frequent maintenance.

Applications of HTA Oil Seals

HTA oil seals find applications across various industries due to their versatile nature and robust design. Some common applications include

- Automotive Industry In vehicles, HTA seals are used in engines, transmissions, and differentials. Their ability to withstand high temperatures and pressures makes them ideal for intensive automotive applications.

- Industrial Machinery Manufacturing and construction equipment often rely on HTA oil seals to protect hydraulic systems and ensure smooth operation under heavy loads.

- Aerospace The aerospace industry utilizes HTA oil seals in engines and gearboxes, where performance and reliability are critical. The high temperature and pressure conditions within aircraft require seals that can perform without failure.

- Agricultural Equipment In agricultural machinery, HTA seals help keep critical systems functioning smoothly by preventing contamination and lubricant loss.

Conclusion

HTA oil seals are essential components for machinery performance, particularly in high-temperature and challenging operating conditions. Their ability to prevent leaks and keep contaminants at bay ensures that engines and other mechanical systems operate efficiently and effectively. As industries continue to evolve, the demand for reliable sealing solutions like HTA oil seals will remain strong, making them a vital part of modern engineering and machinery maintenance.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories