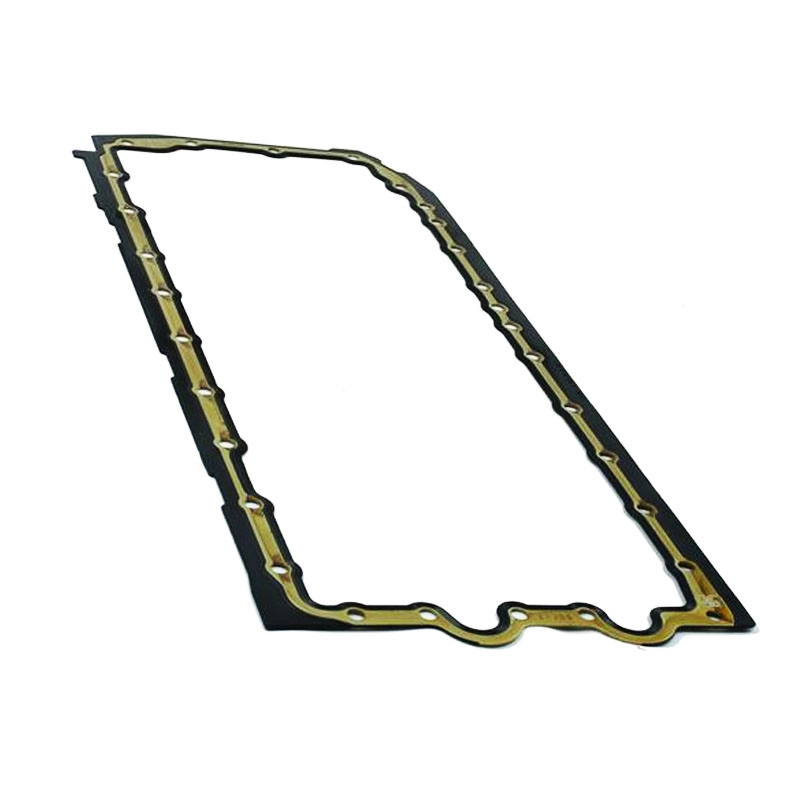

hornet oil seal

The Importance of Hornet Oil Seals A Deep Dive into Performance and Durability

In the realm of mechanical engineering and automotive design, the importance of oil seals cannot be overstated. Among the various types available in the market, hornet oil seals have emerged as a preferred option for many applications due to their robust construction and reliable performance. Understanding the features and advantages of hornet oil seals can significantly enhance the performance and longevity of machinery and vehicles alike.

What is a Hornet Oil Seal?

A hornet oil seal is a specific type of sealing device designed to prevent the leakage of lubricants (like oil or grease) from machinery while simultaneously protecting the internal components from external contaminants such as dust, dirt, and moisture. These seals are typically made from high-quality materials like nitrile rubber, which offers excellent resistance to wear, heat, and various chemicals. Hornet oil seals are meticulously engineered to provide a perfect fit and establish an effective barrier, ensuring that the lubricants remain where they belong.

Key Features of Hornet Oil Seals

1. Durability One of the standout features of hornet oil seals is their durability. Designed to withstand extreme conditions, these seals can maintain their integrity in high-temperature or high-pressure environments. This durability translates to fewer replacement intervals and reduced maintenance costs.

2. High Resistance Hornet oil seals exhibit excellent resistance to oils, greases, and various chemicals. This makes them suitable for various applications, from automotive engines to industrial machinery. Their ability to resist degradation due to chemical exposure prolongs their lifespan and reliability.

3. Tailored Designs Hornet oil seals come in various sizes and shapes, allowing for customization based on specific machinery requirements. Depending on the application, different lip configurations and materials can be selected, ensuring optimal sealing performance.

hornet oil seal

4. Ease of Installation The design of hornet oil seals allows for easy installation, reducing the time and labor costs associated with machinery assembly. Proper installation is crucial for achieving a reliable seal, and hornet oil seals are designed with this in mind.

5. Cost-Effectiveness While the initial investment in hornet oil seals might be slightly higher than that of generic alternatives, their longevity and performance make them a cost-effective choice in the long run. Fewer replacements and decreased downtime translate to higher productivity and lower operational costs.

Applications of Hornet Oil Seals

Hornet oil seals find extensive use across various industries. In the automotive sector, they are commonly used in engines, transmissions, and differentials to ensure efficient lubrication and minimize leaks. In industrial machinery, these seals are crucial for pump assemblies, gearboxes, and hydraulic systems, protecting internal components from contamination and ensuring smooth operation.

Moreover, hornet oil seals are also prevalent in marine applications, where they help protect vital machinery from harsh environmental conditions. Their ability to withstand saltwater and humidity makes them an ideal choice for boats and ships.

Conclusion

In conclusion, hornet oil seals are essential components in modern machinery and vehicles, providing reliable sealing solutions that enhance performance and durability. Their unique features, including high resistance to chemicals, durability, and ease of installation, make them a preferred choice for various applications. As industries continue to innovate and push the limits of engineering, the demand for high-performance sealing solutions like hornet oil seals will undoubtedly grow.

Whether you are a manufacturer looking to improve your product’s reliability or a mechanic aiming to offer the best service to your clients, investing in quality hornet oil seals is a decision that will pay dividends in terms of performance and longevity. By understanding the advantages and applications of these seals, you can make informed choices that keep your machinery running smoothly and efficiently for years to come.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories