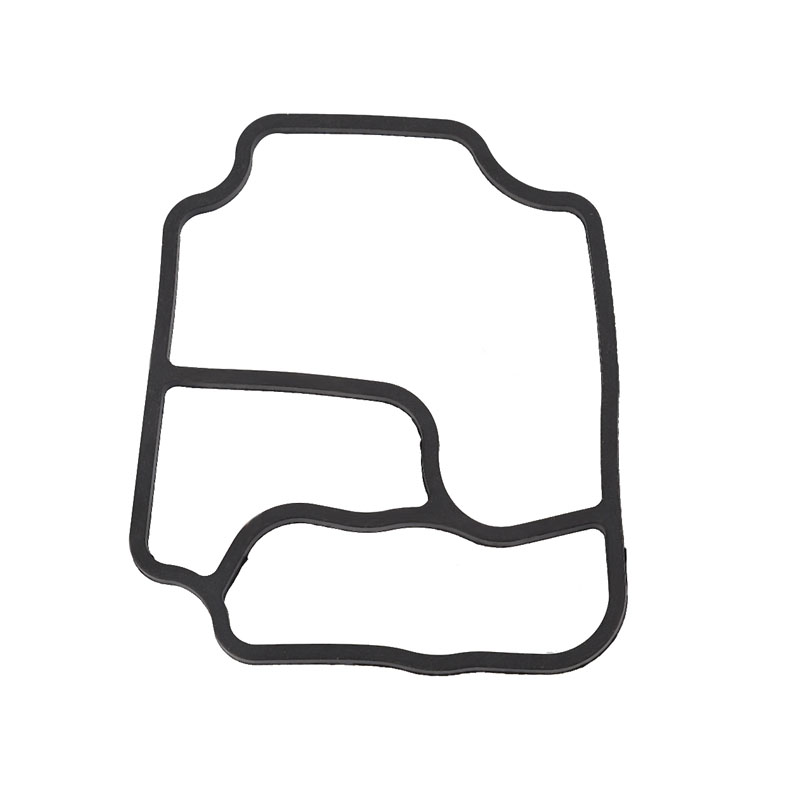

high temp oil seal

Understanding High Temperature Oil Seals Applications, Benefits, and Considerations

High temperature oil seals play a crucial role in various industrial applications, providing critical sealing solutions that enhance the performance and longevity of machinery. These seals are specifically designed to withstand high temperatures and aggressive oil environments, making them an essential component in sectors ranging from automotive to aerospace and manufacturing. In this article, we will explore the key characteristics, benefits, applications, and considerations related to high temperature oil seals.

What are High Temperature Oil Seals?

High temperature oil seals are crafted from specialized materials that allow them to maintain their integrity and functionality even when exposed to elevated temperatures and harsh chemical media. Typically made from elastomers such as silicone, fluorocarbon (Viton), or other high-performance polymers, these seals are designed to provide robust sealing solutions. Their primary function is to prevent lubricant leakage, protect against contaminants, and maintain pressure within the machinery.

Key Characteristics

1. Temperature Resistance High temperature oil seals can operate effectively in environments typically ranging from -40°C to over 200°C (-40°F to 392°F), depending on the material. Some advanced materials can even withstand temperatures up to 300°C (572°F). 2. Chemical Compatibility These seals are engineered to resist various oils, solvents, and chemicals, ensuring that they do not degrade or lose sealing properties when in contact with aggressive substances.

3. Durability High temperature oil seals are built to endure constant mechanical stress, fatigue, and wear, thus prolonging the life of the equipment they protect.

4. Low Friction The design and materials used in high temperature oil seals often result in minimal friction, which contributes to improved energy efficiency and lower operational costs.

Benefits of Using High Temperature Oil Seals

1. Enhanced Equipment Reliability By preventing oil leaks and protecting against contaminants, high temperature oil seals contribute to the overall reliability of machines. This reliability is essential in industries where equipment failure can lead to costly downtimes.

2. Longer Service Life With their ability to withstand extreme conditions, these seals tend to outlast standard seals, leading to reduced maintenance needs and lower replacement costs.

3. Improved Performance High temperature oil seals help maintain optimal lubrication in machinery, which ensures efficient operation and reduces the risk of overheating or damage.

high temp oil seal

4. Versatile Applications These seals can be used in various applications, from automotive engines and transmissions to industrial pumps, compressors, and gearboxes.

Applications

High temperature oil seals find application in numerous industries, including

- Automotive Used in engines, transmissions, and differentials to prevent oil leaks and ensure efficient operation. - Aerospace Essential in aircraft engines and systems where high reliability and performance are non-negotiable. - Manufacturing Employed in hydraulic systems, conveyors, and heavy machinery to protect against contaminants and maintain lubrication. - Marine Utilized in boat engines and gear systems to ensure durability under harsh environmental conditions.

Considerations When Choosing High Temperature Oil Seals

When selecting high temperature oil seals for your application, several factors should be considered

1. Temperature Range Ensure that the chosen seal can withstand the specific temperature conditions it will encounter. 2. Chemical Exposure Evaluate the compatibility of the seal material with the lubricants and chemicals it will come in contact with.

3. Pressure Requirements Determine the pressure conditions in which the seal will operate, as this can influence material selection and design.

4. Size and Fit Accurate sizing is crucial for effective sealing. Measure the gland properly to ensure a proper fit.

5. Manufacturer Expertise Choose seals from reputable manufacturers who provide detailed specifications and testing data to ensure quality.

Conclusion

High temperature oil seals are a vital component in ensuring the efficiency and reliability of machinery operating in demanding environments. By understanding their characteristics and applications, industries can make informed decisions that enhance equipment performance and longevity. As technology continues to advance, the development of even more resilient and efficient sealing solutions will play a critical role in various sectors, paving the way for future innovations.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories