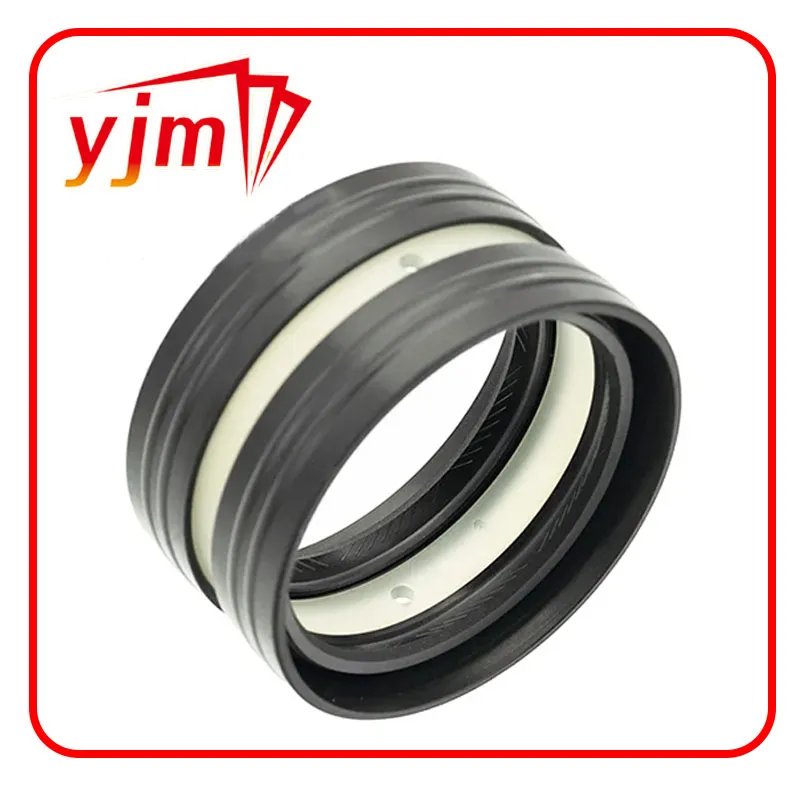

high pressure rotary shaft seals

High Pressure Rotary Shaft Seals An Overview

Rotary shaft seals are critical components in numerous industries, playing an essential role in preventing fluid leakage and protecting machinery from contaminants. Among the various types of seals, high pressure rotary shaft seals are specially designed to operate efficiently under severe conditions, such as elevated pressure and temperature. This article delves into the fundamentals of high pressure rotary shaft seals, their applications, benefits, and maintenance considerations.

Understanding High Pressure Rotary Shaft Seals

High pressure rotary shaft seals are engineered to maintain a tight seal between rotating shafts and stationary housings, effectively containing lubricants and fluids while preventing external contaminants from entering the machinery. These seals are typically made from advanced materials such as rubber compounds, fluoropolymers, or thermoplastic elastomers that offer enhanced resistance to temperature fluctuations, pressure spikes, and chemical exposure.

The design of high pressure seals often incorporates a flexible lip that comes into contact with the shaft. This lip is crucial for maintaining contact under dynamic conditions, ensuring a consistent, reliable barrier against leakage. The geometry of the seal, along with the operating conditions, dictates the choice of materials and construction methods, thus influencing the seal’s performance and lifespan.

Applications of High Pressure Rotary Shaft Seals

High pressure rotary shaft seals are widely used across various industries, including

1. Hydraulic Systems In hydraulic machinery, such as excavators and hydraulic presses, these seals prevent hydraulic fluid from leaking under high pressure, ensuring operational efficiency and safety. 2. Automotive In automobiles, high pressure seals are crucial in engines, transmissions, and power steering systems, providing durability and reliability in challenging environments.

3. Aerospace The aerospace industry requires high-performance seals for turbine engines and landing gear components to withstand extreme pressures and temperatures during flight operations.

4. Oil and Gas In the oil and gas sector, these seals help in downhole drilling applications and pipeline systems, providing robust sealing solutions against high pressures while maintaining fluid integrity.

5. Pharmaceutical and Food Processing In industries requiring stringent hygiene standards, high pressure rotary shaft seals made from FDA-approved materials maintain cleanliness while containing process fluids.

high pressure rotary shaft seals

Benefits of High Pressure Rotary Shaft Seals

The advantages of using high pressure rotary shaft seals include

- Leak Prevention Their robust design ensures effective sealing at high pressures, significantly reducing the risk of leaks that could lead to environmental hazards or equipment failure.

- Extended Equipment Life By keeping contaminants out and lubricants in, these seals contribute to the longevity of machinery and reduce maintenance costs over time.

- Versatility High pressure rotary shaft seals can be tailored to suit a variety of applications and operating conditions, making them versatile components in engineered systems.

- Enhanced Performance With high-quality materials and precision engineering, these seals ensure optimal performance, even under extreme conditions.

Maintenance and Considerations

To ensure the longevity and effectiveness of high pressure rotary shaft seals, regular maintenance is essential. Periodic inspections can help identify wear and tear or signs of leakage early on. Additionally, ensuring that the environment around the seal is clean and free of debris can significantly extend its lifespan.

When selecting a high pressure rotary shaft seal, factors such as operating temperature, pressure, speed of rotation, and the type of fluid being sealed should be carefully considered. Consulting with a seal manufacturer or a sealing solutions expert can provide valuable insights and recommendations tailored to specific applications.

Conclusion

High pressure rotary shaft seals are indispensable components in many industries, ensuring operational efficacy and safety by preventing leaks and protecting machinery from contamination. With proper selection, installation, and maintenance, these seals can provide reliable performance, ultimately contributing to the efficiency and longevity of various mechanical systems. As technologies evolve, the development of more advanced materials and designs will continue to enhance the capabilities of high pressure rotary shaft seals, addressing the ever-increasing demands of modern engineering applications.

-

Essential Guide to Oil Seals: From Radial to Metal-Cased Seals for Industrial Reliability

News Jul.30,2025

-

Choosing the Right Oil Seals and Gaskets for Industrial and Automotive Applications

News Jul.30,2025

-

Cassette Seals: Durable Sealing Solutions for Harsh Environments

News Jul.30,2025

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

Products categories