high heat o rings

High Heat O-Rings Essential Components for Extreme Conditions

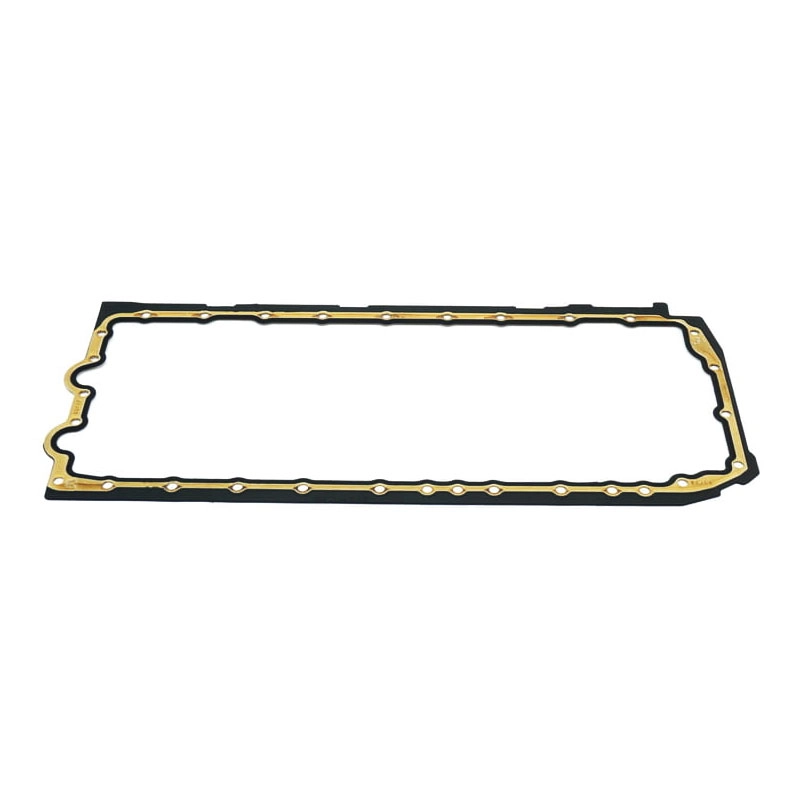

In various industries, from aerospace and automotive to oil and gas, high heat O-rings play a crucial role in ensuring the reliability and efficiency of systems operating under extreme conditions. O-rings, typically circular in shape, are mechanical gaskets used to seal the connection between two or more surfaces. Their primary function is to prevent the leakage of fluids or gases from a sealed environment. However, when it comes to high-temperature applications, the materials and design of O-rings must be tailored to withstand significant thermal stress.

Understanding High Heat O-Rings

High heat O-rings are engineered specifically to endure elevated temperatures that exceed the capabilities of standard O-ring materials. Traditional materials, such as nitrile rubber, generally perform well at moderate temperatures, but when the heat rises beyond 200°C (392°F), these materials can degrade, leading to potential leaks, inefficiencies, and system failures. To combat these challenges, manufacturers utilize specialized compounds designed to remain functional beyond typical thermal limits.

Silicone, fluorocarbon (FKM), and perfluoroelastomer (FFKM) are among the most common materials used in high heat O-ring production. Each of these materials has unique properties that make them suitable for various high-temperature environments. For example, silicone O-rings maintain flexibility at temperatures as high as 230°C (446°F), and FKM can tolerate even higher temperatures, often reaching up to 300°C (572°F) in certain applications.

Applications and Industries

The applications for high heat O-rings are vast, highlighting their importance across multiple sectors. In the aerospace industry, O-rings are employed in critical engine components, fuel systems, and hydraulic systems, where they must endure extreme temperatures and pressures while maintaining airtight seals. In automotive manufacturing, high heat O-rings are crucial for sealing systems involving turbochargers and exhaust components, where high thermal exposure is a regular occurrence.

high heat o rings

Moreover, the oil and gas industry also relies heavily on these O-rings, particularly in drilling and extraction processes that often operate in high-pressure, high-temperature environments. Equipment used in these environments must be dependable to prevent catastrophic failures, making the choice of a reliable high heat O-ring essential.

Factors to Consider

When selecting a high heat O-ring, several factors need to be considered to ensure optimal performance. One primary factor is the temperature range of the application; understanding the maximum and minimum temperatures that the O-ring will encounter is vital. Additionally, the type of fluid or gas being sealed is crucial, as certain materials may react negatively with specific chemicals, leading to degradation of the O-ring.

Another important consideration is the hardness of the O-ring material, which can affect sealability and compression set resistance. A softer O-ring may provide a better seal under certain conditions, but a harder material may be required for durability in a high-temperature application.

Maintenance and Lifespan

Regular maintenance and inspection of high heat O-rings are necessary to ensure their longevity and effectiveness. Signs of wear, such as deformation, cracking, or discoloration, can indicate that the O-ring is nearing the end of its lifespan. Replacing O-rings proactively can prevent leaks and maintain the integrity of the system.

In conclusion, high heat O-rings represent a vital component across various high-temperature applications. Their ability to withstand extreme conditions while providing reliable sealing solutions makes them indispensable in critical industries. Selecting the right material, understanding the application requirements, and maintaining these components can lead to improved efficiency and safety across many operations. As industries continue to evolve and push the limits of technology, the importance of high heat O-rings will undoubtedly grow, highlighting the need for continuous innovation and development in sealing solutions.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories