High Temperature O-Rings for Extreme Conditions | Reliable Seal Solutions

Understanding High-Temperature O-Rings A Key Component in Engineering

O-rings are essential components used in various industries, including aerospace, automotive, manufacturing, and oil and gas. Their primary function is to create a seal between different components, preventing the leakage of fluids or gases. When it comes to high-temperature applications, the choice of material and design becomes critically important to ensure reliability and performance under extreme conditions. In this article, we will explore the significance of high-temperature O-rings, their materials, applications, and best practices for selecting the right one.

Understanding High-Temperature O-Rings A Key Component in Engineering

The temperature range for high-temperature O-rings can vary significantly depending on the material. For instance, Viton O-rings can typically operate up to 250°C (482°F), while certain perfluoroelastomers can handle temperatures as high as 300°C (572°F). The specific application will dictate the material selection and temperature rating needed to ensure optimal performance.

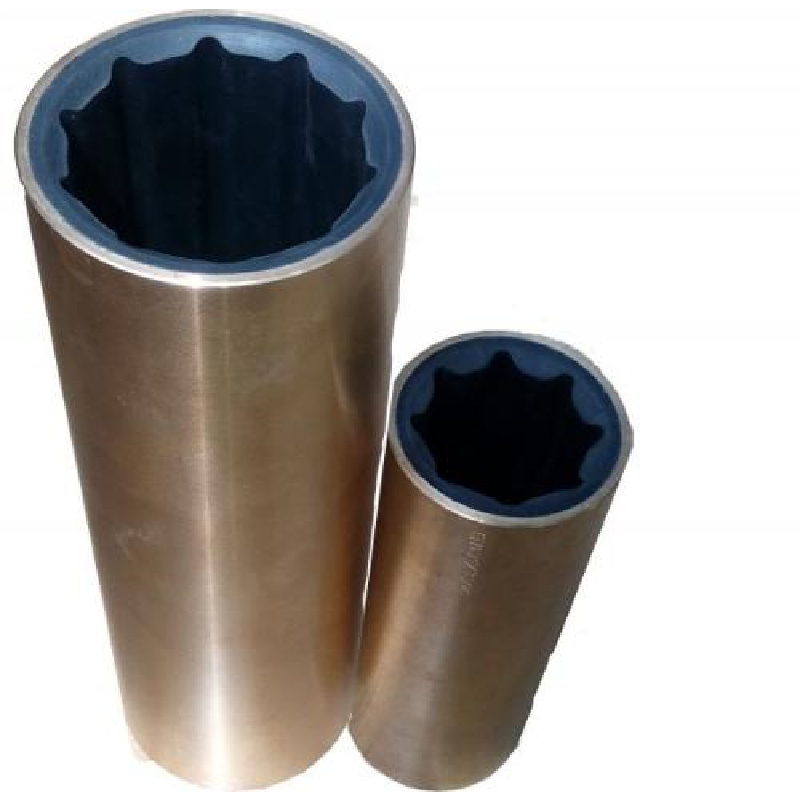

high temp o rings

Applications for high-temperature O-rings are widespread and critical. In the aerospace industry, they are employed in engine components, fuel systems, and hydraulic systems where exposure to high temperatures and aggressive fuels is common. Similarly, in the automotive sector, high-temperature O-rings are used in engine seals, transmission assemblies, and exhaust systems. Moreover, industries such as oil and gas rely on these O-rings for equipment used in drilling, refining, and transportation of fluids at elevated temperatures.

When choosing high-temperature O-rings, several factors must be considered. First and foremost is the operating temperature range of the application. It is equally important to assess chemical compatibility with the fluids or gases with which the O-ring will interact. Additionally, the pressure under which the O-ring will function must be taken into account, as this will influence the required thickness and material selection.

Moreover, the installation process is crucial. Proper installation can prevent premature failure. Ensuring that the groove design accommodates thermal expansion, and using lubrication can significantly enhance the lifespan of high-temperature O-rings. Regular inspections and maintenance are also recommended to identify any signs of wear or degradation.

In summary, high-temperature O-rings are vital components that ensure the integrity of seals in extreme environments. With the right material selection and proper installation, they can provide reliable performance in applications where standard O-rings would fail. As technology advances and industries evolve, the demand for specialized O-rings capable of withstanding high temperatures will continue to grow, underscoring their importance in engineering and manufacturing processes.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories