Durable Seals for Heavy-Duty Applications to Ensure Maximum Performance and Longevity

Heavy Duty Seal The Ultimate Solution for Industrial Applications

In the world of industrial applications, the requirement for high-performance materials is paramount. One such essential component, often overlooked, is the heavy duty seal. These seals play a critical role in ensuring the reliability and efficiency of machinery and equipment across a variety of industries, including automotive, manufacturing, and aerospace. This article delves into what heavy duty seals are, their applications, and why they are indispensable in maintaining operational excellence.

Understanding Heavy Duty Seals

Heavy duty seals are specially designed components that prevent the leakage of fluids and protect against contaminants in high-pressure and high-temperature environments. Unlike standard seals, these heavy-duty versions are constructed from advanced materials that can withstand harsher conditions without compromising their integrity. Commonly made from materials such as fluoropolymers, rubber, and polyurethane, they are engineered to resist abrasion, chemical exposure, and extreme temperatures, making them suited for heavy industrial applications.

Key Features of Heavy Duty Seals

1. Durability One of the most significant features of heavy duty seals is their exceptional durability. They can endure extreme mechanical stresses and environmental conditions, which are prevalent in industries like oil and gas, mining, and construction. This durability translates into longer service life and reduced maintenance costs.

2. Chemical Resistance Heavy duty seals are often exposed to aggressive chemicals. Therefore, they are designed to resist corrosive substances, such as hydrocarbons, acids, and alkalis. This chemical resistance is crucial in industries where the consequences of seal failure can lead to catastrophic results.

3. Temperature Tolerance Operations in industrial environments often involve extreme temperatures. Heavy duty seals can be designed to function effectively at both high and low temperatures, ensuring that they maintain their sealing properties in fluctuating thermal conditions.

4. Customizability Many manufacturers offer customizable solutions to meet specific requirements, such as size, shape, and material composition. This flexibility allows industries to find the perfect seal for their unique applications and challenges.

5. Ease of Installation Heavy duty seals are engineered for easy installation and replacement, minimizing downtime during maintenance or repair. This feature is particularly beneficial in high-output environments where time is critical.

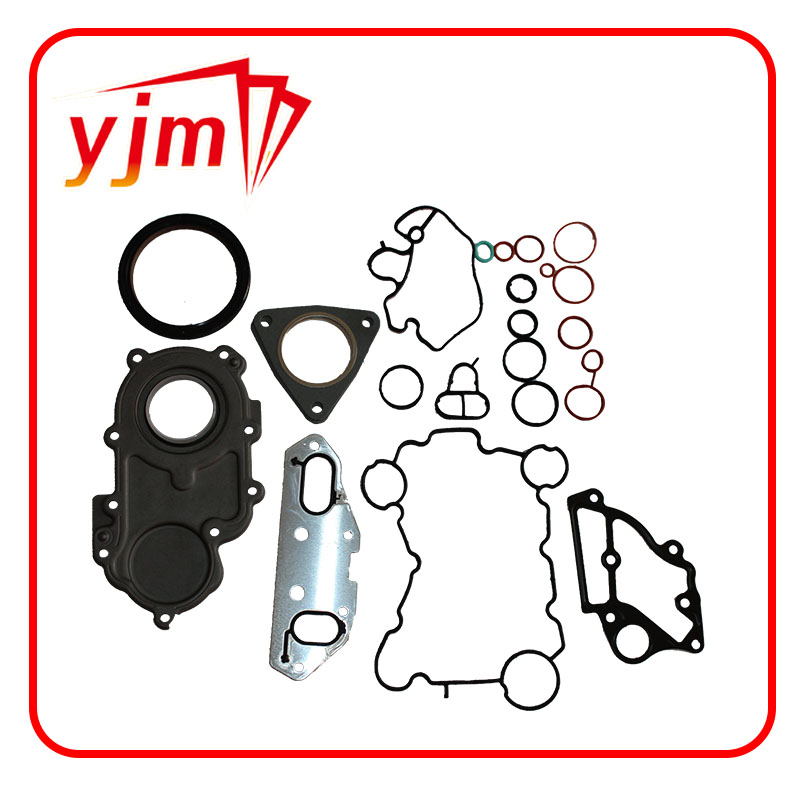

heavy duty seal

Applications of Heavy Duty Seals

Heavy duty seals find applications across various sectors due to their robust design and reliability. Some notable applications include

- Automotive Industry Used in engines, transmissions, and differentials, these seals prevent fluid leaks and protect critical components from dirt and moisture.

- Oil and Gas Industry In drilling and extraction processes, these seals are essential for preventing leaks that can have severe environmental and safety implications.

- Aerospace Heavy duty seals are used in aircraft systems to prevent the ingress of dust, moisture, and other contaminants, ensuring the performance and safety of flight operations.

- Manufacturing In heavy machinery, these seals are critical for maintaining hydraulic systems and ensuring the smooth operation of equipment.

- Marine Applications In marine environments where exposure to saltwater and harsh conditions is common, heavy duty seals protect vital components and systems from corrosion and wear.

Conclusion

In conclusion, heavy duty seals are an integral component of modern industrial applications. Their unique features, including durability, chemical resistance, and temperature tolerance, make them indispensable for maintaining the reliability and performance of machinery and equipment. By investing in high-quality heavy duty seals, industries can reduce maintenance costs, improve operational efficiency, and ensure the longevity of their equipment. As technology continues to advance, the innovation in seal designs will undoubtedly enhance the capabilities of heavy duty seals, further solidifying their role in various industrial sectors. Understanding the importance of these seals is essential for any industry that depends on precision and reliability in its operations.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories