Heavy Duty Seal for Ultimate Protection | Plastic & Rubber Options

Introduction to Heavy Duty Seal Technology

In modern machinery, the reliability of sealing solutions directly impacts operational efficiency, longevity, and overall safety. Heavy duty seal products—including heavy duty plastic seals, heavy duty rubber seal, and heavy seal assemblies—play a pivotal role in protecting sensitive mechanical components against contamination, lubricant leakage, and environmental ingress.

This comprehensive guide explores the latest industry trends, technical parameters, and diverse industrial applications of heavy duty seal technology. We’ll further focus on

a renowned and highly efficient product: the 43800 Oil Seal, proudly manufactured by leading industry authority, JULU YJM HWMF SEAL CO.,LTD.

Industry Trends: Why Heavy Duty Seal Matters

- Global Expansion of Manufacturing and Automation: The demand for reliable heavy duty seal solutions rises as industries—automotive, agricultural, mining, and power generation—seek higher durability in extreme conditions.

- Focus on Sustainability: Latest research in polymer technologies and recycling drives the adoption of advanced elastomers and NBR (Nitrile Butadiene Rubber), extending the service life of heavy duty rubber seal products.

- Digitalization & Predictive Maintenance: Integration of IoT sensors with heavy duty seal systems allows real-time monitoring, reducing downtime and maintenance costs.

Reference: Sealing Industry Forum Discussion

Key Parameters of Heavy Duty Seal Solutions

| Parameter | Plastic Seal | Rubber Seal | 43800 Oil Seal (NBR) |

|---|---|---|---|

| Material | Polyamide (PA6/PA66) | NBR, FKM, EPDM, Silicone | Nitrile Rubber (NBR) |

| Temperature Range | -40℃ to +100℃ | -40℃ to +120℃ | -40℃ to +100℃ |

| Max Working Pressure | 1.2 MPa | 1.5 MPa | 1.4 MPa |

| Typical Applications | Transport locks, meters | Gearboxes, Axles, Pumps | Rotary shafts, Engines, Gearboxes |

| Design Standard | ISO 17712 | DIN 3760/3761 | SCOT1 |

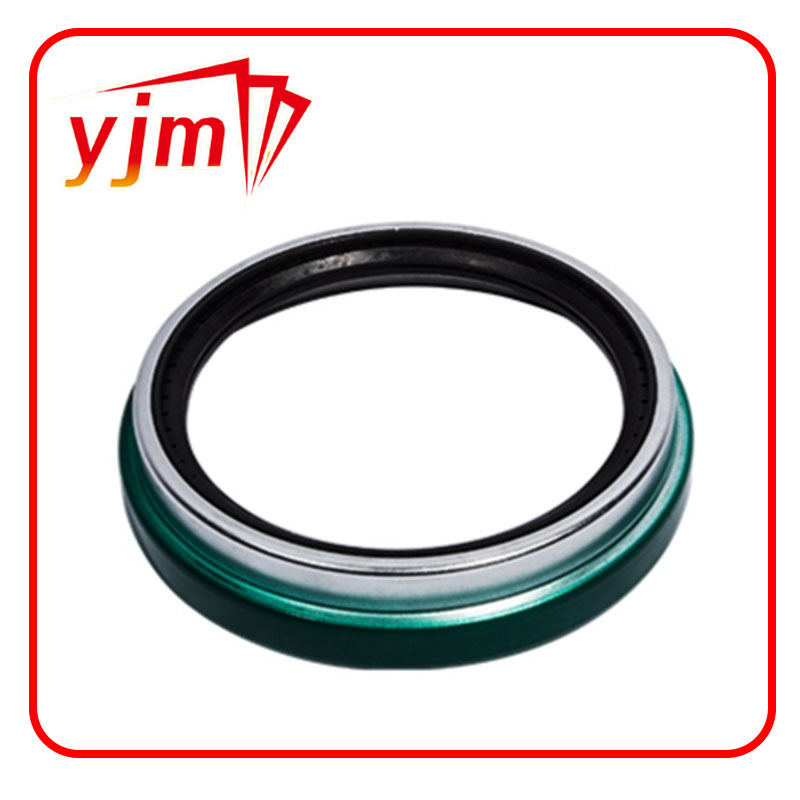

43800 Oil Seal: Premium Heavy Duty Rubber Seal for Industry Leaders

43800 Oil Seal is a robust, high-performance heavy seal solution featuring a nitrile rubber (NBR) lip and metal shell. Its application-specific design ensures enhanced lubricant retention, particulate exclusion, and minimal rotary friction.

- Shaft Diameter: 4.375 inch (111.13 mm)

- Outer Diameter: 6.003 inch (152.48 mm)

- Overall Width: 1.047 inch (26.62 mm)

- Lip Material: High-grade Nitrile Rubber (NBR)

- Design: SCOT1 – Spring Assisted, Single Lip

Applications of Heavy Duty Seal Technologies

- Automotive Industry: Differential and transmission protection, engine crankshaft oiling systems.

- Heavy Machinery: Mining trucks, agricultural harvesters, and construction equipment.

- Industrial Gearboxes: Precision rotary shaft sealing under high pressure and temperature.

- Energy Production: Gas and wind turbines, hydroelectric powerplant mechanicals.

- Fluid Handling: Sealing in pumps, valves and hydraulic systems subjected to contaminants.

Heavy Duty Seal Technical Parameter Trends

43800 Oil Seal - Main Technical Index Data Visualization

Heavy Duty Seal: Expert FAQ – Terminology & Standards

-

Q: What materials are commonly used for heavy duty seal manufacturing?

A: Nitrile rubber (NBR), fluorocarbon (FKM), EPDM, silicone for rubber seals; polyamide and polycarbonate for plastic seals. Metal casing and springs are typically made from stainless or carbon steel. -

Q: What are the standard sizes and tolerances for heavy seal products?

A: Sizes adhere to international standards—e.g., DIN 3760/3761, ISO 6194—covering shaft diameters from 10mm to 500mm, typical OD tolerances within ±0.15mm. -

Q: How does the SCOT1 design of 43800 Oil Seal improve performance?

A: SCOT1 incorporates a spring-assisted lip for stable radial pressure, improving oil retention and dirt exclusion under high-speed and high-temperature operation. -

Q: What installation practices ensure optimal heavy duty rubber seal performance?

A: Always use clean, lubricated shaft surfaces of correct hardness/roughness (Ra 0.2-0.8 μm), use appropriate tools, and avoid excessive distortion. -

Q: What max temperature and pressure can heavy duty seal withstand?

A: Premium NBR-based seals (like 43800 Oil Seal) withstand up to 100°C continuous, 1.4 MPa operating pressure. -

Q: How are heavy duty plastic seals used in cargo and transportation?

A: As security tags or tamper-evident locks, providing cost-effective anti-theft protection meeting ISO 17712 standards. -

Q: How to select between single-lip and double-lip heavy duty seal?

A: Single-lip for general oil/lubricant retention; double-lip adds dust exclusion, suitable for highly contaminated environments.

JULU YJM HWMF SEAL CO.,LTD. – Your Reliable Partner in Heavy Duty Seal Solutions

With decades of engineering excellence, JULU YJM HWMF SEAL CO.,LTD. stands as a leader in heavy duty seal manufacturing and supply.

Our rich product range, including the flagship 43800 Oil Seal, ensures seamless operation for automotive, heavy machinery, and energy sectors globally.

Get in touch today for technical consultation and custom heavy duty seal solutions >>

- Tel: 0086-319-3791512

- Mobile: 0086-319-3791515

- Email: yjm006@hwmf.com

- Address: JULU INDUSTRY AREA, XINGTAI CITY, HEBEI PROVINCE, CHINA 055250

Final Thoughts & Industry References

The rapid evolution of heavy duty seal technology is fueled by advancements in materials science, digitalization, and rising industrial demands. For critical applications, choosing a proven heavy duty seal partner like JULU YJM HWMF SEAL CO.,LTD. can make all the difference in uptime, maintenance savings, and operational reliability.

- Sealing Industry Forum: Latest on Heavy-Duty Oils Seals

- ScienceDirect: Advances in Recycled Polymer-Based Seals

- Seal Society Journal: Oil Seal Material Developments (PDF)

For additional technical support, product inquiries, or to download full spec sheets on heavy duty seal products, please visit our official website.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories