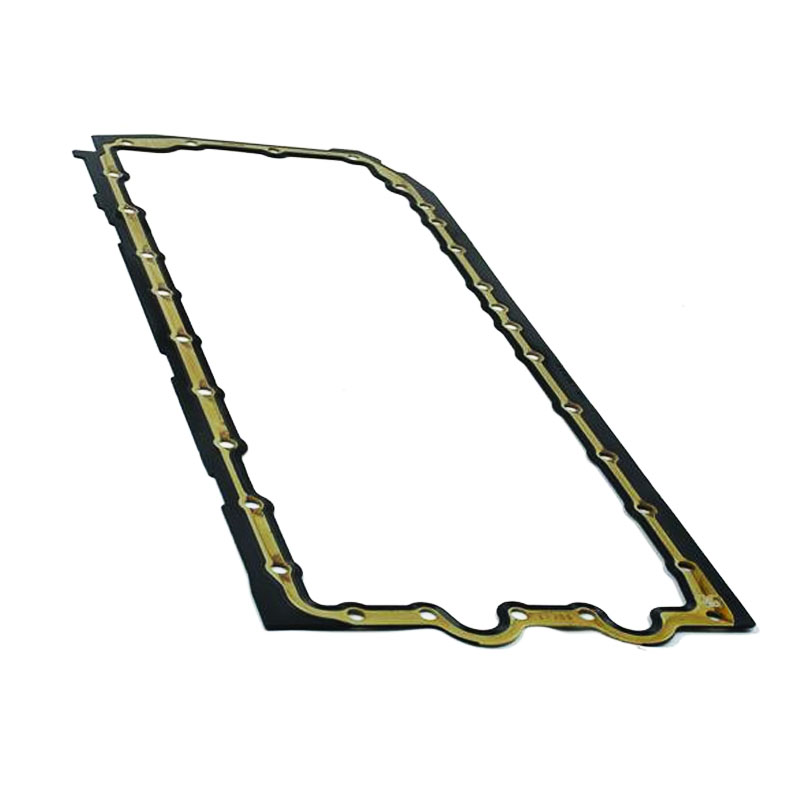

graphite seal ring

The Graphite Seal Ring A Critical Component in Sealing Technology

In the industrial landscape, sealing technology plays a pivotal role in ensuring the efficiency and reliability of various systems. Among the different sealing materials and designs available, the graphite seal ring has emerged as a significant component due to its unique properties and versatility. This article explores the characteristics, applications, advantages, and considerations surrounding graphite seal rings in various industries.

What is a Graphite Seal Ring?

A graphite seal ring is a sealing device made from graphite, a form of carbon known for its excellent thermal stability, chemical resistance, and low friction properties. These seal rings are typically used to create a tight seal between moving parts or to prevent the leakage of gases and liquids in various mechanical systems. The material’s layered structure allows it to accommodate slight variations in surface irregularities, making it ideal for applications requiring a reliable seal under challenging conditions.

Unique Properties of Graphite

Graphite is uniquely suited for high-temperature and high-chemical environments. It can withstand extreme temperatures, often exceeding 1000°C (1832°F) in inert atmospheres, and remains stable even under intense pressure. Furthermore, graphite exhibits good chemical resistance; it is impervious to many acids, bases, and solvents, which makes it suitable for use in chemical processing industries.

One of graphite's most notable features is its self-lubricating property, which is essential in reducing friction between moving parts. This property not only extends the life of the components being sealed but also enhances overall system efficiency. Additionally, graphite is lightweight, which contributes to reduced energy consumption in applications where weight is a critical factor.

Applications in Industry

Graphite seal rings are used across various industries, including oil and gas, power generation, automotive, and manufacturing. In the oil and gas sector, graphite seals are employed in pumps, valves, and compressors to handle aggressive media while preventing leaks and enhancing safety. In power generation, these seal rings are used in steam turbines and reactors where high temperatures and pressures are present.

graphite seal ring

The automotive industry also benefits from graphite seal technology, particularly in engine and exhaust systems. Graphite seal rings help maintain engine integrity by preventing oil and coolant leaks, thereby increasing reliability and performance. Additionally, they are increasingly used in renewable energy applications, such as geothermal energy systems, where they help maintain efficiency by sealing high-pressure systems.

Advantages of Graphite Seal Rings

One of the primary advantages of graphite seal rings is their ability to operate under extreme conditions without compromising performance. Their resilience leads to reduced maintenance costs and improved system uptime. Unlike traditional seal materials, graphite seals do not harden or deteriorate over time, which minimizes the risk of failures due to seal wear.

Moreover, graphite seal rings are environmentally friendly; they do not release harmful substances, making them suitable for eco-conscious industries. Their long-lasting nature also indicates a reduced need for frequent replacements, contributing to lower material waste over time.

Challenges and Considerations

Despite their numerous advantages, graphite seal rings are not without challenges. Their brittleness can make them susceptible to cracking if not handled carefully during installation. Proper design and installation are crucial to maximizing their effectiveness and lifespan.

Another consideration is the potential for creep or dimensional stability issues under sustained load, particularly at elevated temperatures. Engineers must factor in these aspects when designing systems requiring graphite seals to ensure optimal performance.

Conclusion

The graphite seal ring is a vital component in modern sealing technology, offering unparalleled performance in extreme conditions. Its unique properties make it ideal for various industrial applications and contribute to improved system efficiencies and safety. As industries continue to evolve and demand higher performance from their components, graphite seal rings will undoubtedly play a crucial role in meeting these challenges. With proper design, installation, and maintenance, they will continue to be a reliable solution in the ever-changing landscape of industrial engineering.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories