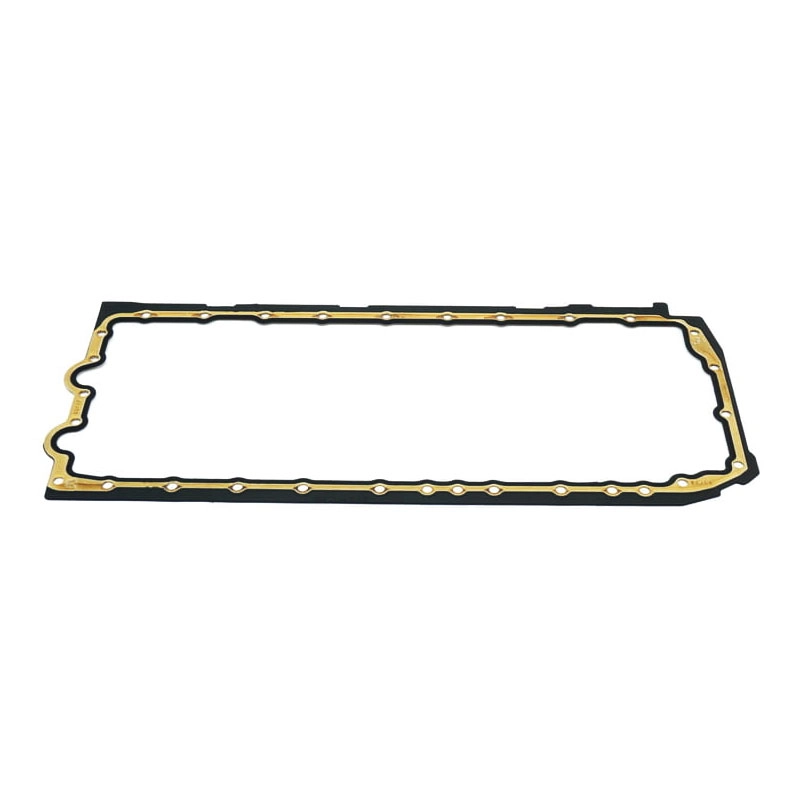

graphite seal ring

Understanding Graphite Seal Rings A Vital Component in Sealing Technology

Graphite seal rings play a crucial role in modern sealing technology, offering unique properties that make them ideal for a variety of applications across multiple industries. These components are essential in ensuring leak-proof seals in systems involving gases, liquids, and even high-pressure environments. In this article, we will explore the characteristics, advantages, applications, and future prospects of graphite seal rings.

What is a Graphite Seal Ring?

A graphite seal ring is a circular sealing element made primarily from graphite materials. Graphite, being a form of carbon, is exceptionally resistant to high temperatures, making it suitable for use in environments where traditional elastomeric seals would fail. The structure of graphite allows it to maintain integrity under extreme conditions, including high pressure and corrosive substances. This durability makes graphite seal rings indispensable in various engineering applications.

Characteristics of Graphite Seal Rings

The unique properties of graphite seal rings stem from the inherent characteristics of graphite itself

1. High Temperature Resistance Graphite can withstand temperatures exceeding 1000 degrees Celsius without significant degradation. This property is essential in industries such as oil and gas, where sealing applications often experience extreme thermal conditions.

2. Chemical Inertness Graphite is largely resistant to many chemicals, including acids and alkalis. This chemical stability ensures that the sealing material does not react with the fluids it is in contact with, thereby extending the life of the seal and maintaining system integrity.

3. Low Friction Graphite exhibits excellent lubricating properties. When used in seals, it reduces friction between moving parts, leading to lower wear and tear over time. This means less frequent maintenance and replacement, resulting in cost savings over the life cycle of the equipment.

4. Flexible and Adaptable Graphite seal rings can be designed in various shapes and sizes to fit different applications. They can be manufactured to specific tolerances to ensure a perfect fit, thus providing a reliable seal without the risk of leakage.

Advantages of Using Graphite Seal Rings

graphite seal ring

The use of graphite seal rings offers several advantages over traditional sealing materials

- Longevity Due to their high resistance to wear and tear, graphite seal rings tend to have a longer lifespan compared to conventional seals. This longevity translates into fewer replacements and less downtime for maintenance, which is critical in demanding industrial environments.

- Cost-Effectiveness Although the initial cost of graphite seals may be higher than that of rubber seals, the long-term savings in maintenance and replacement costs make them an attractive option for many industries.

- Versatility Graphite seal rings can be used in a variety of applications, from sealing joints in pumps and valves to applications in the aerospace and automotive industries. Their ability to handle varying environments and conditions makes them a versatile choice across different sectors.

Applications of Graphite Seal Rings

Graphite seal rings find applications in numerous fields, including

- Oil and Gas Industry Used in pumps, compressors, and valves where high temperatures and chemical exposure are common. - Chemical Processing Effective in sealing equipment handling corrosive substances. - Aerospace Engineering Essential in high-stakes environments where reliability is paramount. - Power Generation Utilized in turbines and generators to ensure efficiency and safety.

Future Prospects

As industries strive for greater efficiency and sustainability, the demand for advanced sealing solutions continues to grow. Graphite seal rings, with their high performance and longevity, are well-positioned to meet these emerging needs. Ongoing research and development are likely to yield even more innovative designs, enhancing their applications and improving performance metrics.

In conclusion, graphite seal rings represent a significant advancement in the field of sealing technology, combining durability, chemical resistance, and cost-effectiveness. Their growing presence in various industrial sectors underscores the importance of reliable sealing solutions in maintaining operational efficiency and safety. As we continue to innovate and improve our sealing technologies, graphite seal rings will undoubtedly play a central role in shaping the future of engineering applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories