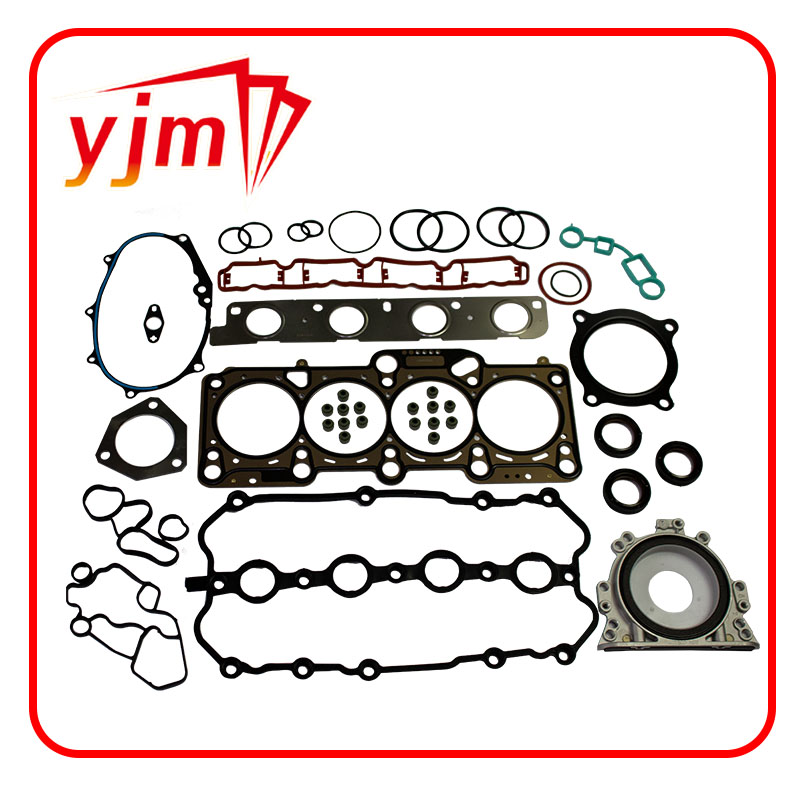

Seal oil filter housing Engine Side BMW Petrol 11427537293

From an expert perspective, regular maintenance of the transmission seal can dramatically extend the lifespan of a GE washer. Conduct periodic inspections for any early signs of wear and clean around the seal to prevent grime buildup. It's advisable to keep a spare seal on hand, especially in areas where access to replacement parts may be delayed. When selecting a replacement transmission seal, it is important to consider the specifications provided by GE. Using genuine parts not only ensures that the washer operates at peak efficiency but also maintains any warranties still in effect. Non-OEM parts, although cheaper, tend to compromise on quality and can lead to more frequent repairs, ultimately costing more in the long run. The authority and reliability of the advice provided here are backed by ongoing industry developments and updates from GE appliance specialists. Staying informed about such updates can be beneficial; subscribing to GE's service bulletins or newsletters can provide useful maintenance tips and alerts for any recalls or design improvements. To sum up, taking proactive steps to understand and manage the transmission seal in your GE washer is an essential aspect of appliance care. By leveraging expert advice and utilizing authoritative sources for your replacement parts, you secure your appliance's longevity and functionality. Keeping a vigilant eye on the wear and tear of components, and addressing issues promptly with professional guidance, ensures that your GE washer remains a reliable and efficient part of your household.

-

High-Quality Seal 12x22x5 for Industrial & Automotive Use | YJM Seal

News Nov.25,2025

-

Seal 12x20x5: Precision Radial Shaft Seals for Industrial Reliability

News Nov.24,2025

-

Seal 12x18x5: Essential Guide to Specifications, Applications & Vendors

News Nov.24,2025

-

Understanding Seal 12 20 5: Applications, Specifications & Industry Insights

News Nov.23,2025

-

Durable Oil Seal 85x110x12 – Reliable Sealing Solutions for Industry

News Nov.23,2025

-

Durable and Precise Oil Seal 75x95x10 for Efficient Machinery | YJM Seal

News Nov.22,2025

-

Durable Oil Seal 75x100x10 for Reliable Industrial Performance | YJM Seal

News Nov.22,2025

Products categories