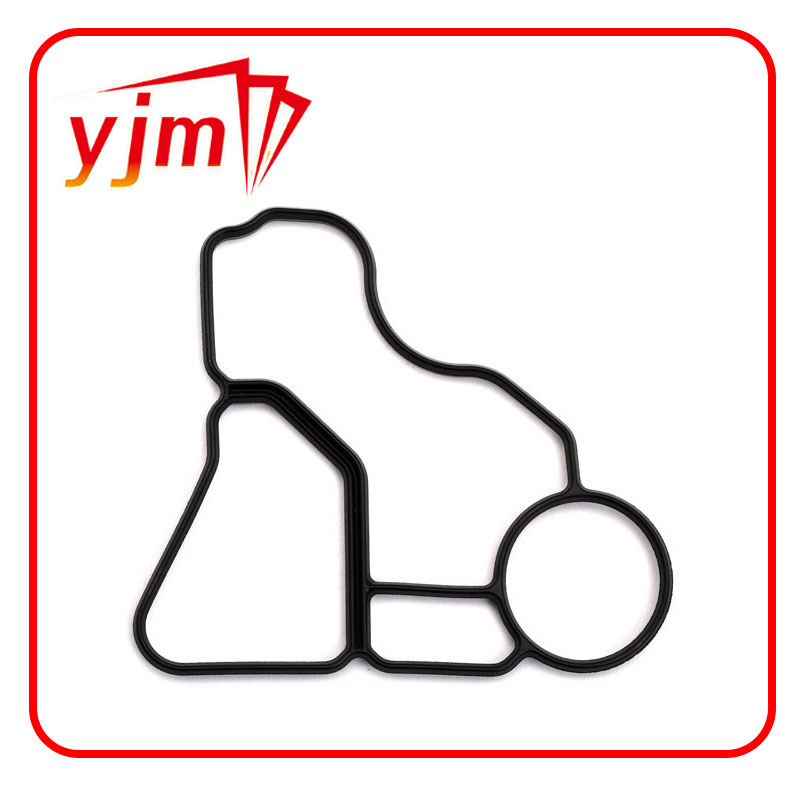

generator oil drain plug

The Importance of Proper Maintenance of Generator Oil Drain Plugs

Generators play a vital role in supplying power, especially in areas where electricity is unreliable or unavailable. Whether used for residential backup, commercial purposes, or in industrial applications, ensuring your generator is running efficiently is paramount. One often overlooked component in generator maintenance is the oil drain plug. This small yet crucial part can significantly impact the performance and longevity of your generator.

Understanding the Oil Drain Plug

The oil drain plug is a small, threaded component located at the bottom of the oil reservoir in a generator. It serves two main purposes it allows for the removal of used or contaminated oil and helps to keep the oil reservoir sealed. Since engines generate heat, the oil within them gets degraded over time. Regular oil changes are essential for optimal operation, and the drain plug is how this maintenance is performed.

The Role of the Oil Drain Plug in Maintenance

Regularly changing the oil in your generator helps remove harmful contaminants that can accumulate with usage. The oil drain plug facilitates this process and assists in draining the old oil completely. Removing as much old oil as possible ensures that the new oil can perform its function effectively. Any residual oil mixed with the new oil may reduce its effectiveness and lead to friction and wear of engine components.

Common Issues with Oil Drain Plugs

While the oil drain plug is a simple component, it can lead to significant issues if not properly maintained. Here are a few common problems associated with generator oil drain plugs

1. Leakage Over time, wear and tear can lead to leaks around the oil drain plug. This may occur due to an improper seal, damaged threads, or the plug being over-tightened. Leaking oil is not only wasteful but can also lead to severe engine damage if the oil level drops too low.

2. Stripped Threads If the oil drain plug is repeatedly over-tightened or not screwed in correctly, the threads may become stripped. This makes it challenging to secure the plug properly, leading to further leaks and oil loss.

3. Dirt and Debris Accumulation During regular operation, dirt and debris can accumulate around the oil drain plug, potentially contaminating the oil. This makes it crucial to clean the area around the plug before draining the oil.

generator oil drain plug

Tips for Maintaining Your Oil Drain Plug

To avoid issues with the oil drain plug and ensure optimal generator performance, consider the following maintenance tips

- Regular Inspections Periodically check the oil drain plug for signs of damage, corrosion, or leakage. Address any issues promptly to avoid larger problems in the future.

- Clean the Area Before performing an oil change, clean the area around the oil drain plug to prevent dirt from entering the oil reservoir.

- Use New Washers When replacing the oil drain plug after an oil change, consider using a new washer to ensure a good seal and prevent leaks.

- Tighten Properly Avoid over-tightening the drain plug. Follow the manufacturer’s specifications for torque settings to ensure a secure yet gentle fit.

- Keep Records Maintain a log of oil changes and inspections, noting any observations regarding the drain plug. This practice helps track the condition of your generator over time.

Conclusion

The oil drain plug may seem like a small component, but it plays a significant role in the maintenance and efficiency of your generator. By understanding its importance and implementing regular checks and maintenance, you can ensure that your generator operates smoothly and efficiently, ultimately extending its lifespan. Regular attention to this small but vital part will pay off in reliability and performance, ensuring that you have a dependable power source when you need it most.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories