Understanding Gearbox Seals for Optimal Performance and Longevity

The Importance of Gearbox Seals in Mechanical Systems

Gearboxes are essential components in many mechanical systems, allowing for the transfer of power and torque from one component to another. Whether in automobiles, industrial machinery, or aerospace applications, the functionality of gearboxes is crucial for performance and efficiency. One often-overlooked aspect of gearbox performance is the role of seals. Gearbox seals are critical for maintaining the integrity and functionality of the gearbox, preventing leaks, and ensuring longevity.

What are Gearbox Seals?

Gearbox seals are specially designed components used to prevent fluid leaks from the gearbox housing. These seals are typically located at strategic points where moving parts intersect with stationary components. The primary functions of gearbox seals are to retain lubrication oil within the gearbox, keep contaminants, such as dirt and dust, from entering, and maintain system pressure.

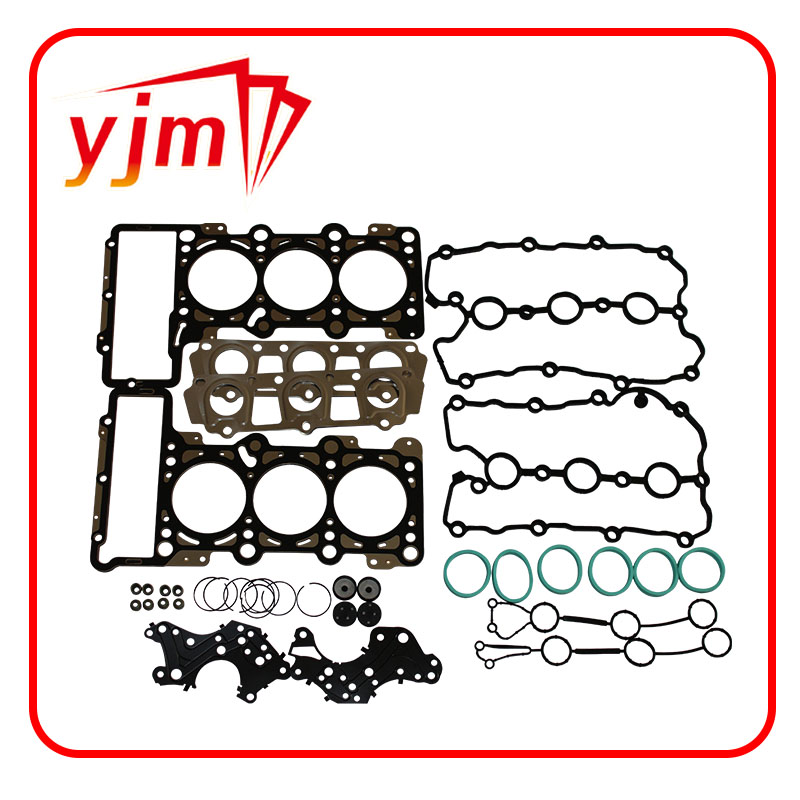

There are various types of seals used in gearboxes, including O-rings, lip seals, and radial seals. Each type has its unique design and application suited for specific operational environments. For example, lip seals are common in applications where higher temperatures and pressures are present, while O-rings offer excellent sealing capabilities in low-pressure systems.

Why are Gearbox Seals Important?

1. Preventing Leaks The most significant function of gearbox seals is their ability to prevent leakage of lubricant. Gear oils are designed to reduce friction between moving parts; if these lubricants escape, it can lead to inadequate lubrication, resulting in increased wear, overheating, and ultimately, gearbox failure. Seals are designed to withstand varying pressures and temperatures, ensuring that the oil remains contained within the gearbox.

2. Contaminant Protection In many environments, gearboxes are exposed to dust, dirt, water, and other contaminants that can lead to operational issues. Proper sealing prevents these harmful particles from entering the gearbox, which could degrade the lubricant and cause damage to the gears and bearings. This protective barrier is vital in extending the operational life of the gearbox and maintaining its performance.

gear box seals

3. Enhancing Efficiency An efficient gearbox operates smoothly and reduces energy consumption. If seals fail and leaks occur, the lubrication system can become compromised, forcing the machinery to work harder. This added strain translates to increased energy use and potential overheating, which can decrease efficiency and lead to costly repairs down the road.

4. Cost Savings Failing to maintain effective seals in a gearbox can lead to significant costs. Not only can it result in the need for expensive repairs, but it can also impact the entire equipment lifecycle, leading to premature failure. Regular inspections and maintenance of gearbox seals can prevent these issues and save money in the long run.

Maintaining Gearbox Seals

To ensure that gearbox seals function correctly, regular inspection and maintenance are essential. Operators should regularly check for signs of wear, such as cracks, hardening, or deformation of the seals. Any signs of leaking should be addressed immediately to prevent further damage.

In addition, the environment where the gearbox operates should be considered. Extreme temperatures, aggressive chemicals, or high pressures can accelerate seal degradation. Selecting the appropriate seal material and design based on operating conditions is crucial for long-term performance.

Finally, during routine maintenance, the seals should be replaced as required. Over time, even the best seals can wear out due to constant exposure to friction and pressure. Keeping spare seals on hand can minimize downtime and ensure that the machinery operates smoothly.

Conclusion

In conclusion, gearbox seals are an essential component of mechanical systems, playing a vital role in preventing leaks, protecting against contaminants, enhancing efficiency, and ultimately saving costs. To maintain optimal performance, operators should prioritize regular inspections and replacements of seals, keeping in mind the specific operating conditions of their equipment. By understanding the importance of gearbox seals, businesses can ensure the longevity and reliability of their machinery, contributing to overall productivity and success.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories