Understanding Gearbox Seal Types and Their Importance in Mechanical Systems

Understanding Gearbox Seals An Essential Component of Mechanical Systems

Gearbox seals are crucial components in various mechanical systems, especially within automotive and industrial machinery. These seals play a vital role in ensuring that gearboxes function efficiently and effectively, preventing fluid leaks and contamination. In this article, we will explore the importance, types, materials, and maintenance of gearbox seals, highlighting their significance in preserving the integrity of machinery.

Importance of Gearbox Seals

The primary function of gearbox seals is to contain lubricating oils and prevent them from leaking out. Lubrication is essential for reducing friction between moving parts within the gearbox, thereby preventing wear and tear, overheating, and eventual mechanical failure. A well-sealed gearbox not only enhances the performance of the machinery but also extends its lifespan and reduces maintenance costs.

Moreover, gearbox seals prevent the ingress of dirt, dust, and other contaminants, which can adversely affect the operation of the gearbox. Contaminated lubricants can lead to increased wear, corrosion, and ultimately, gearbox failure. Therefore, maintaining the integrity of these seals is paramount for the overall health of mechanical systems.

Types of Gearbox Seals

There are several types of gearbox seals, each designed for specific applications and conditions

1. Rotary Lip Seals These are one of the most common types of seals used in gearboxes. They feature a flexible lip that maintains contact with the rotating shaft, effectively preventing oil leaks. Their simple design and effectiveness make them a popular choice.

2. V-Ring Seals V-Rings are designed to be installed on a rotating shaft and maintain a seal against a stationary component. They are particularly useful in applications with varying shaft speeds and are known for their ability to accommodate minor misalignments.

3. O-Rings O-Rings are circular seals that are used in static applications or where there is limited movement. They are often used in conjunction with other sealing methods to enhance sealing integrity.

4. Gaskets In some systems, gaskets are used to seal the joints between different components, such as the gearbox cover and the housing. Gaskets must be made from materials that can withstand the operating conditions of the gearbox.

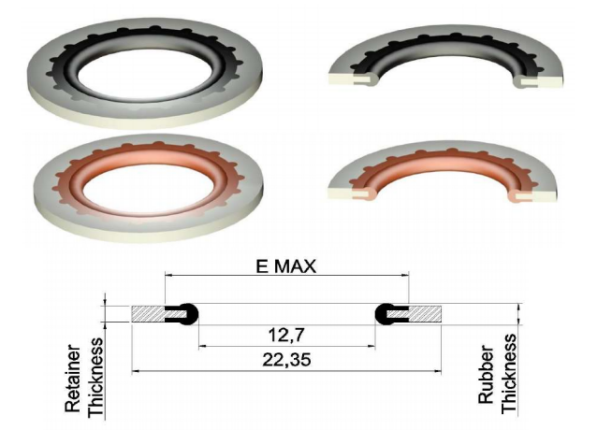

gear box seals

Materials Used in Gearbox Seals

The materials used in manufacturing gearbox seals are critical for their performance and durability. Common materials include

- Nitrile Rubber (NBR) Known for its excellent oil resistance, NBR is one of the most widely used materials for rotary seals. It can operate in a temperature range of -40°C to 100°C.

- Fluorocarbon (FKM) FKM offers superior resistance to high temperatures and aggressive chemicals, making it suitable for heavy-duty applications.

- Polyurethane Known for its toughness and flexibility, polyurethane seals can withstand harsh operating conditions while maintaining sealing efficiency.

- Silicone This material is often used in applications requiring extreme temperature resistance, but is less effective against petroleum-based oils.

Maintenance of Gearbox Seals

Proper maintenance of gearbox seals is essential to ensure their longevity and effectiveness. Regular inspection for signs of wear, such as cracks or deformation, should be part of routine maintenance. Additionally, monitoring oil levels and looking for signs of leakage can help identify potential seal failure early.

In cases where seals need to be replaced, using the correct size and type is crucial. Incorrect seals can lead to insufficient sealing, leading to oil leaks and gear damage.

Conclusion

In conclusion, gearbox seals are integral to the reliable operation of mechanical systems. Understanding their importance, types, and materials can aid in the selection and maintenance of these components. By ensuring that gearbox seals are in optimal condition, operators can safeguard the performance and longevity of their machinery, ultimately leading to increased efficiency and reduced operational costs. Regular inspections and timely replacements of gearbox seals are fundamental practices for maintaining the health of any mechanical system.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories