Alternative Solutions for Gearbox Rubber Seal Performance and Durability Optimization

Understanding Gearbox Rubber Seals Importance, Types, and Applications

Gearbox rubber seals are crucial components in various mechanical systems, playing a vital role in ensuring the efficiency and longevity of gearboxes in automobiles, industrial machinery, and other applications. These seals are designed to prevent the leakage of oil and other fluids, protecting the internal components of gearboxes from contamination and ensuring smooth operation. In this article, we will explore the importance of gearbox rubber seals, the different types available, and their various applications.

Importance of Gearbox Rubber Seals

The primary function of gearbox rubber seals is to maintain the integrity of the gearbox by preventing fluid leakage. Without effective sealing, gearbox oil can escape, leading to a decrease in lubrication. This can cause significant wear and tear on gears and bearings, resulting in costly repairs or replacements. Furthermore, leakage can allow dirt and debris to enter the gearbox, which can lead to further damage and decreased operational efficiency.

In addition to preventing fluid loss and contamination, gearbox rubber seals contribute to the overall performance of the machinery. Properly sealed gearboxes operate more efficiently, as they maintain optimal temperature and pressure levels. This increased efficiency can lead to improved fuel consumption in vehicles and reduced energy costs in industrial applications. Ultimately, using effective rubber seals can enhance the longevity and reliability of gearbox systems.

Types of Gearbox Rubber Seals

There are several types of rubber seals designed for use in gearboxes, each tailored to specific requirements and conditions. Here are some of the most common types

1. O-Rings O-rings are circular seals that provide a tight fit between two mating surfaces. They are commonly used in various applications due to their simplicity and effectiveness. O-rings can come in various materials, including nitrile rubber and silicone, which can withstand different temperature and chemical environments.

2. Lip Seals Lip seals feature a flexible lip that comes into contact with the rotating shaft, creating a tight seal while allowing for some movement. These seals are effective at preventing leaks and are widely used in applications where shafts rotate at high speeds.

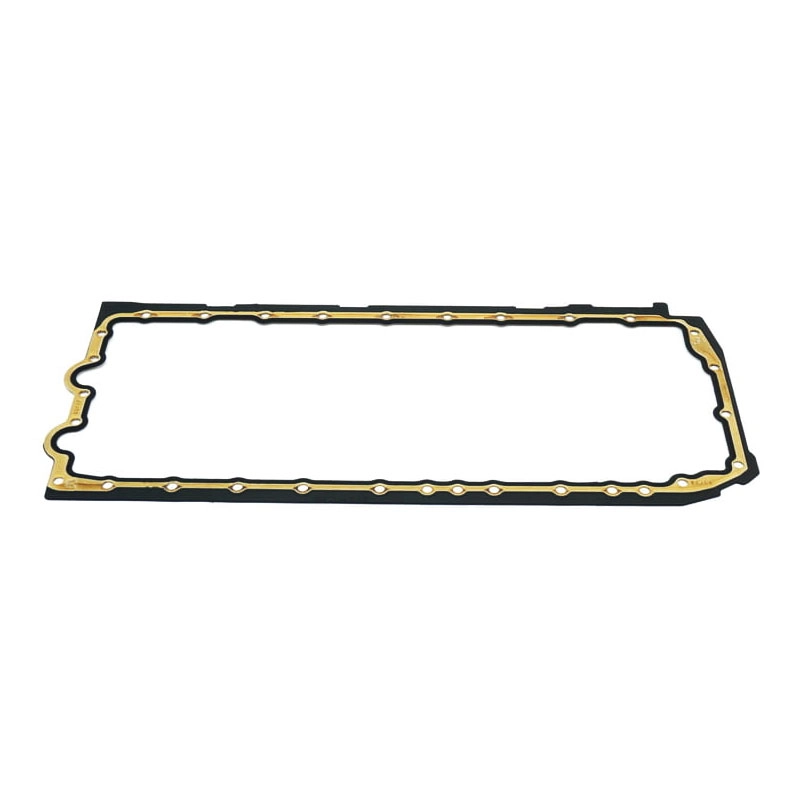

3. Flat Seals Flat rubber seals are used in applications where two flat surfaces need to be sealed together. They are often used in combination with bolts and screws to create a seal that prevents fluid from escaping.

gearbox rubber seal

4. Custom Seals In certain applications, standard seal shapes may not provide the required fit. Custom rubber seals can be manufactured to meet specific dimensions and performance needs, ensuring optimal sealing for unique gearbox designs.

Applications of Gearbox Rubber Seals

Gearbox rubber seals are used in various industries and applications, including

- Automotive Industry In vehicles, gearbox seals are essential for manual and automatic transmissions. They protect against oil leaks, ensuring smooth gear shifting and preventing damage to transmission components.

- Industrial Machinery Gearboxes in industrial equipment require reliable seals to maintain performance and reduce maintenance needs. This is particularly important in environments with heavy loads or high speeds.

- Aerospace In the aerospace industry, sealing applications must meet rigorous performance standards. Rubber seals used in aircraft gearboxes must withstand extreme conditions, such as temperature fluctuations and high pressures.

- Marine Applications Marine gearboxes need robust sealing solutions due to exposure to elements like saltwater. Specially formulated rubber seals can prevent corrosion and ensure reliable performance in challenging environments.

Conclusion

In conclusion, gearbox rubber seals are integral to the optimal operation of various machinery, from automobiles to industrial equipment. Understanding their importance, types, and applications helps manufacturers and engineers select the right sealing solutions for their needs. By ensuring proper sealing, not only can we enhance performance and reliability, but also extend the lifespan of crucial mechanical systems. As technology continues to evolve, the development of advanced rubber seal materials and designs will further improve the efficiency and effectiveness of gearboxes across industries.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories