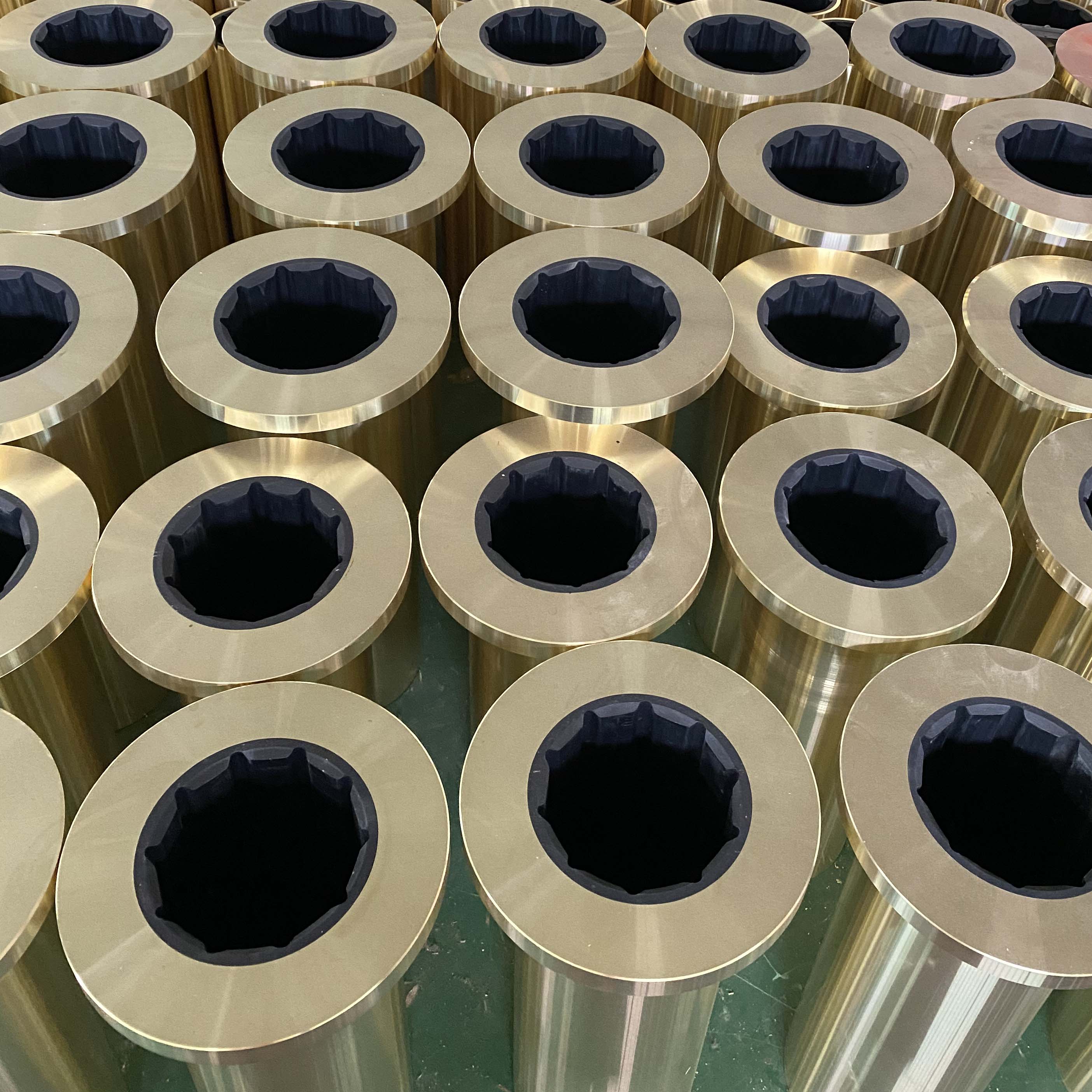

gearbox oil seal

Understanding Gearbox Oil Seals Importance, Types, and Maintenance

Gearbox oil seals play a crucial role in the functionality and longevity of vehicle transmissions and machinery gearboxes. These seals are designed to prevent the leakage of gearbox oil, which is essential for lubricating gears and preventing wear and tear. In this article, we will explore the importance of gearbox oil seals, the different types available, and tips for maintenance to ensure optimal performance.

Importance of Gearbox Oil Seals

The primary function of a gearbox oil seal is to maintain the integrity of the oil within the gearbox. Gear oil is engineered to reduce friction between moving parts, facilitate smooth gear changes, and dissipate heat generated during operation. Without proper sealing, oil can leak out, leading to inadequate lubrication, increased wear, and ultimately gearbox failure. This can result in costly repairs and downtime for vehicles and machinery.

Oil seals also protect the gearbox from external contaminants, such as dirt and moisture, which can compromise the quality of the oil and damage internal components. By keeping contaminants out, oil seals help maintain the performance and reliability of the gearbox over time.

Types of Gearbox Oil Seals

There are several types of gearbox oil seals, each designed for specific applications and conditions. The most common types include

1. Lip Seals These are the most widely used oil seals, featuring a flexible lip that makes contact with the shaft. They create a tight seal that prevents oil leakage while allowing for some axial movement of the shaft. Lip seals are typically made from rubber, polyurethane, or other elastomeric materials.

2. Radial Seals Also known as rotary seals, radial seals function similarly to lip seals but are designed for radial applications. They are commonly used in rotating shafts and can handle both oil and grease.

3. Mechanical Seals Often used in more demanding applications, mechanical seals consist of multiple components that work together to provide a robust sealing solution. They are typically used in high-pressure situations and can handle extreme temperatures and chemical exposure.

4. O-Ring Seals These circular seals are used in a variety of applications and can provide effective sealing for static and dynamic situations. O-rings are versatile and can be made from a variety of materials, including rubber and silicone.

gearbox oil seal

5. V-Seals These seals are used in applications where dirt and moisture are a concern. V-seals are fitted onto shafts and provide a secondary barrier to protect the primary oil seals from contamination.

Maintenance Tips

Proper maintenance of gearbox oil seals can significantly extend their lifespan and ensure the efficient operation of the gearbox. Here are some tips for maintaining gearbox oil seals

1. Regular Inspections Periodically check the oil seals for signs of wear, such as cracks, tears, or deformation. Early detection of issues can prevent oil leaks and subsequent damage.

2. Cleanliness Keep the surrounding area clean. Dirt and debris can accumulate around the seals, leading to premature wear or failure. Regularly clean the gearbox exterior to minimize contamination risks.

3. Correct Installation Ensure that oil seals are correctly installed. Improper installation can cause leaks and may lead to damage of both the seal and the shaft. Always follow manufacturer guidelines during installation.

4. Use Quality Seals Invest in high-quality oil seals that are suitable for your specific gearbox application. Using inferior or incorrect seals can result in leaks and increased maintenance costs.

5. Monitor Fluid Levels Regularly check and maintain the appropriate levels of gearbox oil. Low oil levels can lead to increased friction and heat, putting additional stress on the seals.

Conclusion

Gearbox oil seals are vital components that protect and enhance the performance of gearboxes in vehicles and machinery. Understanding their importance, types, and the need for regular maintenance can ensure that your gearbox operates efficiently and remains reliable over time. By investing in quality seals and maintaining them properly, you can save on costly repairs and prolong the life of your gearbox system.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories