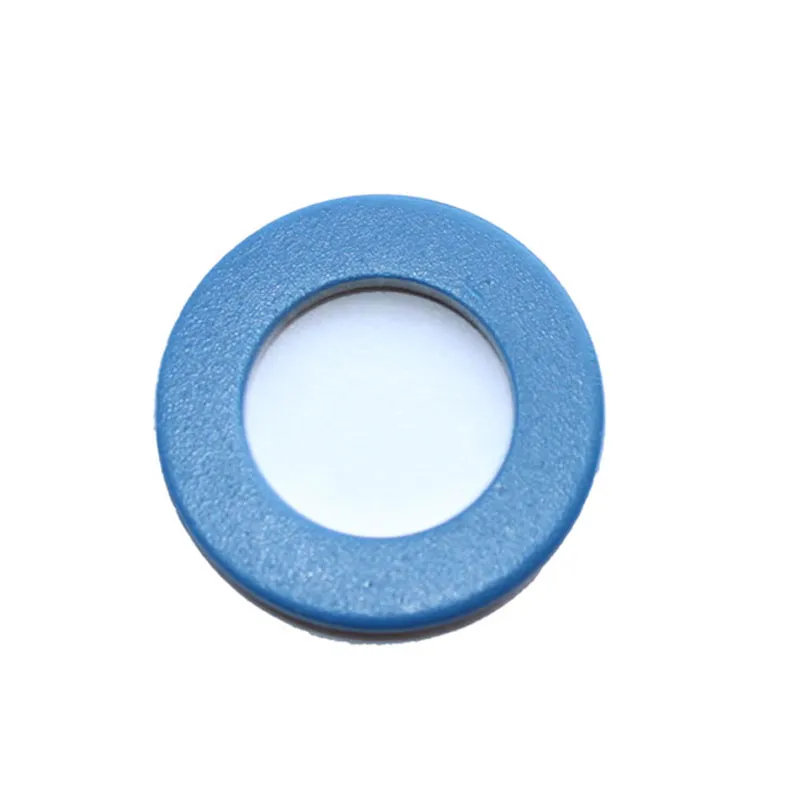

gasoline resistant o rings

Understanding Gasoline-Resistant O-Rings Essential Components for Automotive and Industrial Applications

In the realm of automotive and industrial engineering, the importance of reliable and durable components cannot be overstated. Among these critical parts, O-rings play an essential role in ensuring the efficient operation of various systems. Specifically, gasoline-resistant O-rings are integral in applications that involve exposure to fuel, making them crucial for automotive design, fuel systems, and many industrial applications.

What are O-Rings?

O-rings are circular, donut-shaped seals made from various elastomeric materials. They are designed to be seated in a groove, creating a tight seal when compressed between two mating surfaces. Their simple design belies their effectiveness; O-rings are capable of preventing the leakage of fluids and gases, hence maintaining pressure and improving efficiency in systems.

The Significance of Gasoline-Resistant O-Rings

Gasoline is a complex mixture of hydrocarbons and other volatile substances, which can be corrosive and degrade many common materials. This makes the selection of a compatible O-ring material critical in applications that directly involve gasoline exposure. Gasoline-resistant O-rings are specifically engineered to withstand the chemical properties of gasoline, ensuring longevity and reliability in hostile environments.

These O-rings are particularly significant for the automotive industry, where they are commonly employed in fuel injectors, fuel pumps, and connectors. They prevent fuel leaks, which can lead to performance issues, environmental hazards, and safety risks. Additionally, any failure in the sealing integrity can result in costly repairs and potential non-compliance with safety regulations.

Material Choices for Gasoline-Resistant O-Rings

The choice of material for gasoline-resistant O-rings is crucial and typically includes various compounds such as

1. Nitrile Rubber (NBR) NBR is one of the most common materials for gasoline-resistant O-rings. It offers excellent resistance to petroleum-based fuels and oils, making it suitable for automotive applications. NBR also provides good tensile strength and flexibility.

gasoline resistant o rings

2. Fluoroelastomers (FKM) Fluoroelastomers are another excellent choice for applications requiring exposure to aggressive chemicals, including gasoline. They offer superior thermal stability, resistance to swelling, and retention of sealing properties under extreme conditions. Products such as Viton are well-regarded in sectors requiring high-performance materials.

3. Ethylene Propylene Diene Monomer (EPDM) While EPDM is known for its weathering and ozone resistance, its application in gasoline systems is limited. It is, however, suitable for certain fuel systems exposed only to low concentrations of gasoline or ethanol blends.

4. PTFE (Teflon) This material is renowned for its chemical resistance. While it is typically not used alone for O-rings due to its low elasticity, it is often combined with other materials to enhance performance in applications involving gasoline.

Applications of Gasoline-Resistant O-Rings

Gasoline-resistant O-rings find extensive use in various applications, including

- Automotive Fuel Systems They are critical components in fuel rail assemblies, carburetors, and connectors, ensuring the tight sealing necessary to prevent leaks in high-pressure environments.

- Industrial Equipment Many industrial machines that deal with fuel transfer or storage incorporate gasoline-resistant O-rings to maintain efficiency and safety.

- Outdoor Power Equipment In equipment such as lawnmowers and generators, O-rings help seal fuel lines and tanks, ensuring proper operation and preventing fuel spills.

Conclusion

In conclusion, gasoline-resistant O-rings are indispensable components in modern automotive and industrial applications. Selecting the right material for these O-rings is vital for optimal performance and safety. As the automotive industry continues to evolve, particularly with the rise of electric vehicles and increased focus on environmental impact, the development of more advanced sealing technologies will remain a priority. Nonetheless, for applications involving gasoline, the significance of durable, reliable O-rings will continue to be paramount, serving as the unsung heroes in sealing technology, safeguarding both performance and safety.

-

Simplifying Oil Changes: A Comprehensive Guide to Oil Drain Plugs and Their Variants

News Aug.04,2025

-

Mastering Oil Drain Maintenance: Solutions for Stripped, Worn, and Upgraded Oil Plugs

News Aug.04,2025

-

Fixing Oil Pan Plug Issues: Leaks, Stripped Nuts, and the Right Replacement Solutions

News Aug.04,2025

-

Everything You Need to Know About Oil Drain Plugs: Sizes, Fixes, and Upgrades

News Aug.04,2025

-

Choosing the Right Oil Drain Plug: A Guide to Sizes, Materials, and Drain Innovations

News Aug.04,2025

-

A Complete Guide to Automotive Drain Plugs: Types, Problems, and Innovative Solutions

News Aug.04,2025

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

Products categories