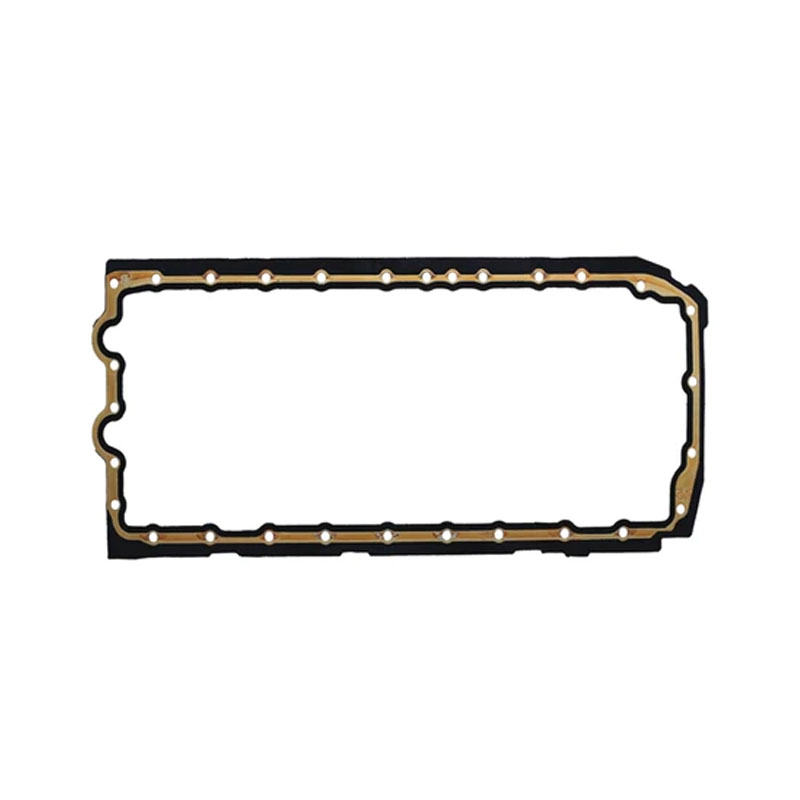

gasket flat

The Importance of Gasket Flats in Engineering Applications

In the world of mechanical engineering and industrial applications, sealing technologies play a vital role in ensuring the integrity and efficiency of various systems. Among the numerous sealing solutions available, gaskets stand out as critical components used to prevent leakage between two mating surfaces. A specific aspect of gaskets that deserves attention is the concept of gasket flats. Understanding gasket flats and their implications is essential for engineers and designers involved in creating reliable mechanical systems.

Gasket flats refer to the flat surfaces that are designed to accommodate gaskets in assemblies where creating a tight seal is necessary. These surfaces are usually machined precisely to ensure uniformity and consistency when the gasket is compressed between them. The effectiveness of a gasket in sealing applications largely depends on the quality of the gasket flats and their ability to maintain proper contact with the gasket material.

One of the primary functions of gasket flats is to support the even distribution of pressure across the gasket. When two flanges are bolted together, the pressure applied needs to be evenly distributed to avoid creating weak points that could lead to leaks. If the gasket flats are not perfectly flat or are uneven, the gasket will not compress uniformly, potentially allowing leakage paths to form. Therefore, maintaining tight tolerances during the manufacturing of gasket flats is crucial in preventing issues related to fluid or gas leakage.

In addition to the flatness specifications, the surface finish of gasket flats also plays a significant role in achieving optimal sealing performance

. A smoother surface finish can enhance the sealing capability of the gasket by reducing the surface area that potentially interacts with the fluid or gas and minimizing the risk of abrasion that can wear out the gasket over time. Conversely, a rough surface may create additional leakage paths due to the increased potential for uneven contact with the gasket material.gasket flat

The choice of materials for the gasket flats is another critical factor in determining the overall performance of the gasket. Different applications require different materials, depending on the environmental conditions, temperatures, and pressures involved. For example, in high-temperature applications, gasket flats made from heat-resistant alloys are preferred. In contrast, applications that involve corrosive substances may necessitate gasket flats made from specialized materials that can withstand chemical attack.

It is also essential to consider thermal expansion when designing gasket flats. As temperatures fluctuate within a system, materials tend to expand or contract. Engineers must account for these dimensional changes to ensure that the gasket remains properly seated within the gasket flats throughout its operational range. Adequate design allowances for potential expansion can prevent issues such as gasket blowout or damage caused by excessive compression.

In many engineering applications, regular maintenance and inspection of gasket flats and the gaskets themselves are essential. Over time, environmental factors, mechanical stress, and thermal cycling can degrade both the gasket and the flats. Regular checks can help identify wear and tear, allowing for timely replacement and ensuring the system continues to operate efficiently and safely.

Additionally, advancements in gasket materials and technologies are continuously evolving. New materials with enhanced elasticity, chemical resistance, and temperature tolerance are being developed, which in turn influences the design and manufacturing of gasket flats. Engineers must stay abreast of these advancements to offer the best solutions for sealing applications.

In conclusion, gasket flats play a significant role in the performance and reliability of sealing applications across various industries. By ensuring precision in machining, attention to surface finish, and careful consideration of material properties, engineers can improve the lifespan and effectiveness of gaskets. As industries continue to evolve, understanding gasket flats will remain a central focus in mechanical design and maintenance, ultimately contributing to improved safety, efficiency, and sustainability in engineering applications.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories