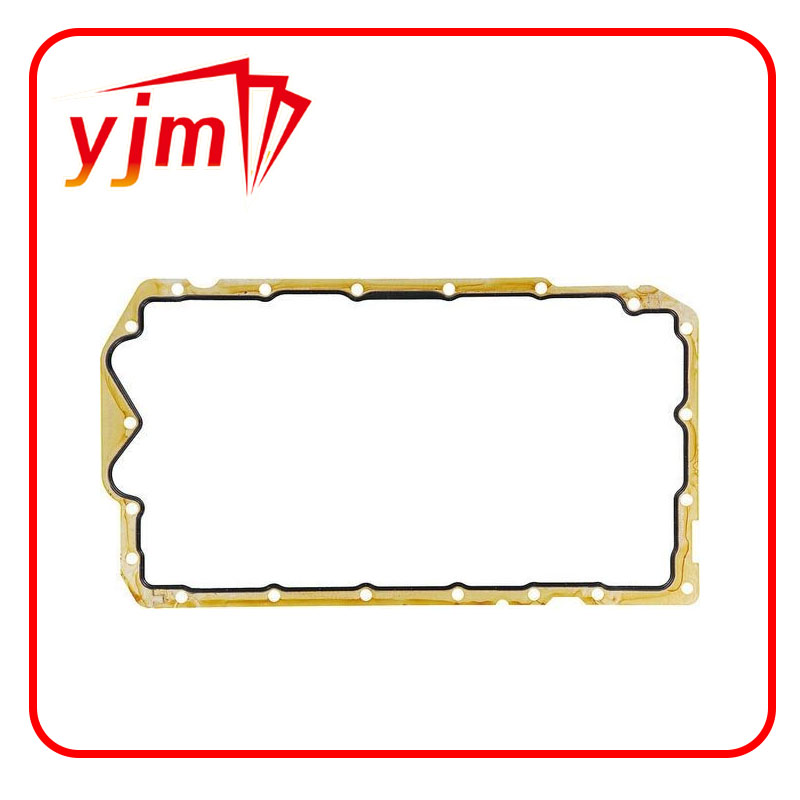

fuel water separator drain plug

Understanding the Importance of the Fuel Water Separator Drain Plug

In the world of machinery and automotive maintenance, the fuel water separator drain plug plays a crucial role in ensuring optimal engine performance and longevity. This component, often overlooked, serves a vital function in protecting engines from the harmful effects of water and debris present in fuel. In this article, we will explore the significance of the fuel water separator, the role of the drain plug, and best practices for maintenance.

What is a Fuel Water Separator?

A fuel water separator is a device designed to separate water and contaminants from fuel before it reaches the engine. Water can enter fuel systems through several channels, including condensation, faulty storage tanks, and during transportation. This water, combined with other impurities, can cause significant damage to engines, leading to costly repairs and downtime. The fuel water separator ensures that the fuel used by the engine is as pure as possible, thereby maintaining engine efficiency and performance.

The Role of the Drain Plug

The drain plug is an integral part of the fuel water separator. It allows for the removal of accumulated water and contaminants that settle at the bottom of the separator. Regularly draining this accumulation is essential, as failure to do so can lead to several negative consequences. If water is not removed, it can mix with the fuel and travel to the engine, leading to misfires, reduced performance, and even potential engine failure.

Additionally, contaminants such as dirt and debris can also build up within the separator. If these contaminants are not removed, they can clog filters, reduce fuel flow, and cause premature wear and tear on engine components. Therefore, the drain plug serves not only as a means of keeping the fuel clean but also as a critical component for ensuring the overall health of the engine.

Maintenance Best Practices

fuel water separator drain plug

To ensure the fuel water separator and its drain plug function effectively, regular maintenance is key

. Here are some best practices to consider1. Regular Inspection Engine operators should routinely check the fuel water separator for signs of accumulated water or debris. This can often be done during regular service intervals.

2. Frequent Draining Depending on operating conditions, it may be necessary to drain the separator more frequently. For example, environments with high humidity or poor-quality fuel may require more regular draining.

3. Monitor Engine Performance Any sudden changes in engine performance, such as rough idling or decreased power, may indicate issues with the fuel system. Investigating these changes can lead to early detection of water or contaminants.

4. Follow Manufacturer Guidelines Each engine and separator system may have specific guidelines about maintenance intervals and procedures. Adhering to these guidelines ensures that the equipment remains in optimal working condition.

5. Professional Servicing For those unfamiliar with engine maintenance, seeking professional assistance can help in properly managing fuel systems. Professionals have the experience and tools necessary to handle potential complications.

Conclusion

The fuel water separator drain plug, while a small component, plays a significant role in maintaining the integrity of fuel systems and overall engine performance. Regular maintenance and monitoring can prevent potential fuel system failures and extend the lifespan of engines. By understanding the importance of this component, operators can take proactive measures to safeguard their equipment, ensuring efficient and reliable performance.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories