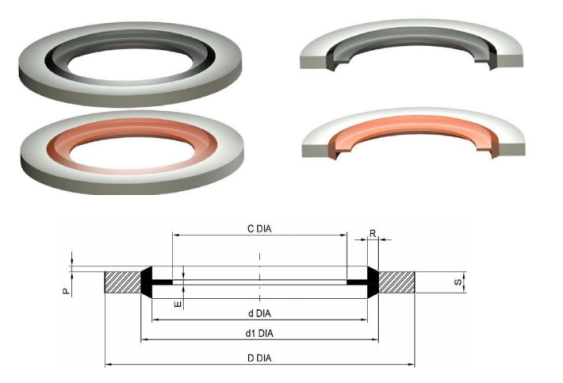

flat rubber gasket seal

Understanding Flat Rubber Gasket Seals Importance, Types, and Applications

Flat rubber gasket seals play a crucial role in various industrial applications, serving as vital components designed to provide a tight seal between two surfaces. These seals are commonly used in scenarios where fluid or gas leakage must be minimized or prevented entirely. They are essential in a multitude of industries, including automotive, aerospace, manufacturing, and plumbing, among others. This article delves into the importance, types, and applications of flat rubber gasket seals.

Importance of Flat Rubber Gasket Seals

Flat rubber gasket seals are critical in maintaining the integrity of machinery and systems. They are designed to endure extreme conditions, including temperature variances, pressure changes, and exposure to chemicals. By providing a reliable sealing mechanism, these gaskets help prevent leaks, which can lead to equipment failure, loss of resources, and safety hazards.

Moreover, flat rubber gaskets contribute to operational efficiency. When properly installed, they reduce maintenance needs by preventing wear and damage to the machinery they are meant to protect. This reliability translates to lowered operational costs and improved productivity.

Types of Flat Rubber Gasket Seals

There are several types of flat rubber gasket seals, each designed to cater to specific needs and applications. Some of the most common materials used for manufacturing flat rubber gaskets include

1. Neoprene This synthetic rubber is known for its resilience and excellent resistance to weathering, ozone, and chemicals. Neoprene gaskets are frequently used in automotive and HVAC applications. 2. Nitrile (Buna-N) Known for its resistance to oil and fuel, nitrile rubber gaskets are ideal for sealing in the automotive and aerospace industries where petroleum products are prevalent.

3. EPDM Ethylene Propylene Diene Monomer (EPDM) is a popular choice for gaskets exposed to high heat and electrical insulation. It’s commonly used in roofing, automotive seals, and electrical enclosures.

4. Silicone Silicone gaskets are favored for their high-temperature resistance and flexibility. They are often utilized in food processing and medical applications due to their inert nature and ability to maintain a sanitary environment.

flat rubber gasket seal

5. Fluoroelastomer This material is utilized for its high chemical resistance and performance in extreme temperatures. They are typically used in advanced automotive and aerospace applications.

Applications of Flat Rubber Gasket Seals

Flat rubber gasket seals are integral to a wide range of applications, showcasing their versatility and essential role in numerous operations

. Here are some common areas where these gaskets are utilized1. Automotive Industry In vehicles, flat rubber gaskets are essential for sealing components such as oil pans, valve covers, and exhaust systems. They prevent oil leaks and ensure optimal engine performance.

2. HVAC Systems In heating, ventilation, and air conditioning systems, flat rubber gaskets are used to seal ductwork, preventing air leaks and improving energy efficiency.

3. Manufacturing Equipment Machinery often has various sealing requirements to reduce waste and maintain safety. Flat rubber gaskets are used in hydraulic and pneumatic systems to seal connections and components.

4. Plumbing In plumbing applications, flat rubber gaskets are routinely employed to seal connections between pipes and fixtures, preventing water leaks and potential damage.

5. Aerospace The aerospace industry relies on flat rubber gaskets to maintain the integrity of aircraft components, withstanding high pressures and extreme environmental conditions.

Conclusion

Flat rubber gasket seals are indispensable elements in numerous industries, ensuring that systems operate smoothly without leaks or inefficiencies. By understanding the importance, types, and diverse applications of these gaskets, industry professionals can make informed decisions regarding their selection and application. Whether in an automotive context or a complex manufacturing environment, the proper use of flat rubber gasket seals is essential to achieving optimal performance and reliability in any mechanical system.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories