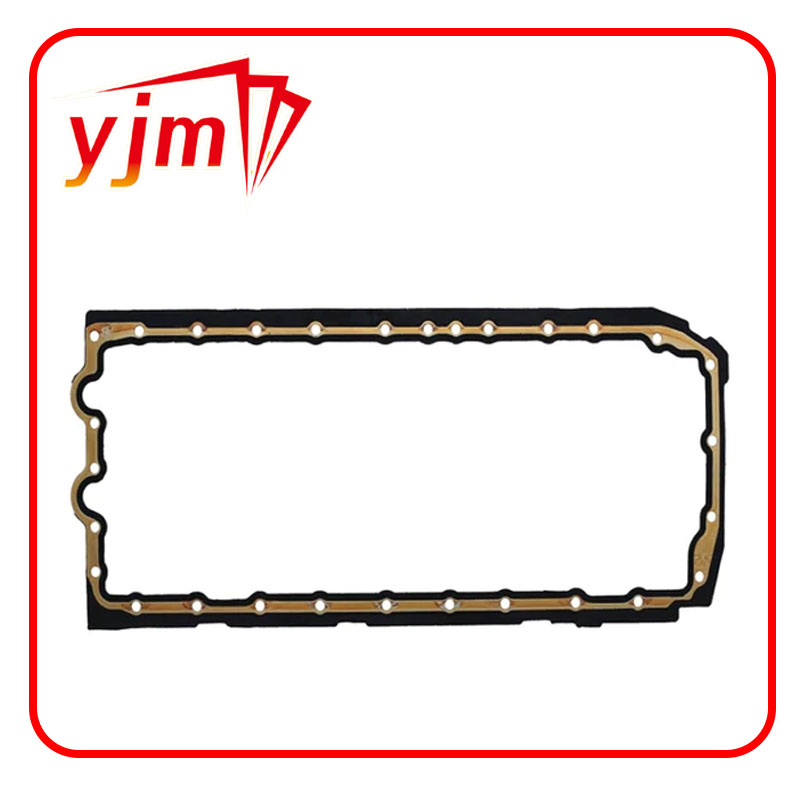

flat round rubber gaskets

Understanding Flat Round Rubber Gaskets Their Importance and Applications

Flat round rubber gaskets are essential components in various industries, serving as an effective barrier against leaks and contaminants. These gaskets are typically used to create seals between two surfaces, effectively preventing the escape of fluids and gases. In this article, we will explore their importance, the materials used in their production, various applications, and best practices for selecting the right gasket for your needs.

What are Flat Round Rubber Gaskets?

Flat round rubber gaskets are circular pieces of rubber that are designed to fit in the space between two mating surfaces. Their primary function is to create a tight, stable seal that prevents the passage of media such as liquids, gases, or dust. They come in a variety of sizes, thicknesses, and materials, allowing for versatile applications across different industrial settings.

Materials Used

The effectiveness of flat round rubber gaskets largely depends on the material from which they are made. Several types of rubber and elastomers are used in gasket manufacturing, including

1. Nitrile Rubber (Buna-N) Known for its excellent resistance to oils and fuels, making it suitable for automotive and industrial applications.

2. EPDM (Ethylene Propylene Diene Monomer) This material is highly resistant to heat, ozone, and weathering, often used in outdoor applications and automotive weather strips.

3. Neoprene Offers good chemical stability and is often used in applications requiring resistance to a wide range of chemicals.

4. Silicone Used for its temperature resistance and flexibility, making it a great choice for high or low-temperature applications.

5. Viton Known for its excellent resistance to high temperatures and aggressive chemicals, making it an ideal choice for high-performance applications.

Selecting the appropriate material for specific applications is crucial for ensuring durability and effectiveness.

Applications of Flat Round Rubber Gaskets

Flat round rubber gaskets are found in numerous industries, including

1. Automotive Used in engines, transmissions, and fuel systems to prevent leaks and maintain performance.

flat round rubber gaskets

2. Aerospace Essential for sealing critical components, ensuring safety and reliability in flight operations.

4. Manufacturing Applied in machinery and equipment to keep fluids contained and prevent contamination.

5. Food and Beverage Compliant with health standards, these gaskets are used in processing equipment, ensuring hygiene and safety.

Factors to Consider When Choosing Gaskets

When selecting flat round rubber gaskets, consider the following factors

1. Temperature and Pressure Ensure the selected material can withstand the operating conditions it will face.

2. Chemical Compatibility Assess the media that the gasket will encounter and select a material that can resist degradation.

3. Size and Thickness Measure the dimensions of the assembly where the gasket will be installed to ensure a proper fit.

4. Environmental Conditions Consider the external environment, including exposure to UV light, ozone, and extreme temperatures.

5. Standards and Regulations Ensure compliance with any industry-specific regulations, particularly in sectors like food and pharmaceuticals.

Proper Installation and Maintenance

Proper installation is key to the performance and longevity of flat round rubber gaskets. Ensure that the mating surfaces are clean and free from debris. Use appropriate torque specifications when tightening bolts to avoid damaging the gasket. Regular inspections should also be conducted to identify signs of wear and tear, replacing gaskets when necessary to prevent leaks.

Conclusion

Flat round rubber gaskets are simple yet vital components in a multitude of industries. Their ability to provide effective seals against leaks and contaminants makes them indispensable for ensuring operational efficiency and safety. By understanding the materials, applications, and selection criteria for these gaskets, manufacturers and engineers can make informed decisions that enhance system reliability and performance. Whether used in automotive, aerospace, plumbing, or food processing, the importance of these gaskets cannot be overstated; they play a key role in keeping systems running smoothly and safely.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories