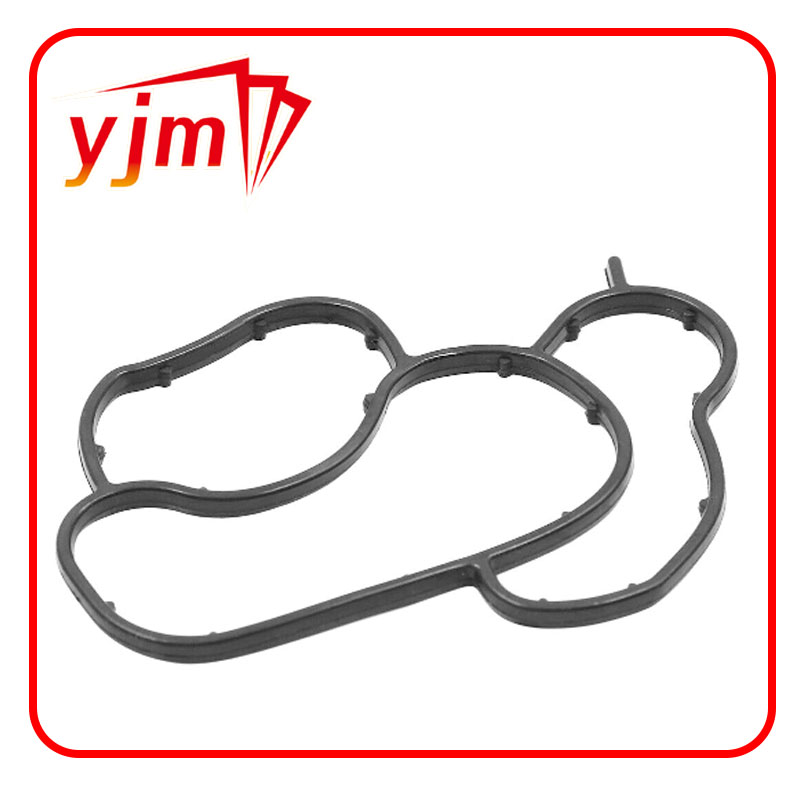

flat ring gasket

Understanding Flat Ring Gaskets Essential Components in Sealing Applications

Flat ring gaskets play an essential role in various engineering and industrial applications. These simple yet crucial components are designed to create a tight seal between two surfaces, preventing the leakage of fluids or gases. Their reliability and efficiency make them a staple in industries ranging from automotive and aerospace to oil and gas. This article delves into the characteristics, types, materials, and applications of flat ring gaskets.

What is a Flat Ring Gasket?

A flat ring gasket is a circular piece of material that is placed between two mating surfaces to fill the void and ensure a tight seal. Unlike some gaskets that have a more complex shape, flat ring gaskets are straightforward in design, which allows for easy installation and maintenance. They are typically used in flange connections, pipe fittings, and static seals where two surfaces need to be securely joined.

Characteristics of Flat Ring Gaskets

1. Material Composition Flat ring gaskets can be made from a variety of materials, including rubber, silicone, cork, graphite, and metal. The choice of material is often dependent on the specific application, taking into consideration factors such as temperature, pressure, and the type of fluid or gas being sealed.

2. Thickness and Size These gaskets come in various thicknesses and diameters to fit different specifications. The thickness can affect the compressibility and sealing ability of the gasket, which is crucial in ensuring a proper seal under varying pressure conditions.

3. Pressure Management Flat ring gaskets are designed to withstand a certain range of pressures. When compressed between two surfaces, they deform slightly to fill any imperfections and create a tightly sealed joint.

Types of Flat Ring Gaskets

Flat ring gaskets can be categorized based on their material and design

- Rubber Gaskets Commonly used for low-pressure applications, rubber gaskets offer excellent flexibility and resistance to a wide range of temperatures. They are widely utilized in plumbing applications.

flat ring gasket

- Metal Gaskets Often found in high-pressure and high-temperature environments, metal gaskets provide superior strength and durability. They are frequently employed in aerospace and automotive applications.

- Composite Gaskets Made from a combination of materials, composite gaskets offer a balance between flexibility and strength. They are versatile and can be used in various industries.

- Non-asbestos Gaskets These gaskets are increasingly popular due to environmental regulations concerning asbestos. They typically use materials like aramid fibers or PTFE to provide effective sealing without the health risks associated with asbestos.

Applications of Flat Ring Gaskets

Flat ring gaskets are found in a myriad of applications, showcasing their versatility

1. Automotive In the automotive industry, flat ring gaskets are used in engine components, fuel systems, and exhaust applications. They help prevent oil leaks and maintain pressure in critical systems.

2. Oil and Gas The oil and gas sector relies on flat ring gaskets for sealing pipe connections in various processing equipment. Their ability to withstand harsh environments is crucial for maintaining safety and efficiency.

3. Aerospace In aerospace applications, flat ring gaskets are used in fuel systems, hydraulic systems, and engines. Their lightweight nature and ability to perform under extreme temperatures make them ideal for this sector.

4. Pharmaceuticals and Food Processing Sanitary gaskets made from FDA-approved materials are essential in the pharmaceutical and food industries to prevent contamination while ensuring effective sealing.

Conclusion

Flat ring gaskets are vital components that ensure the integrity of many engineering systems. Their simplistic design belies their importance, as they provide essential sealing capabilities in a wide range of applications. Understanding the various types of flat ring gaskets and their specific uses can significantly enhance the effectiveness of sealing solutions across multiple industries. When selecting a gasket, it’s crucial to consider the material, thickness, and application requirements to ensure optimal performance and reliability. Whether in automotive applications, industrial machinery, or aerospace technology, flat ring gaskets remain a fundamental yet often overlooked aspect of effective engineering design.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories