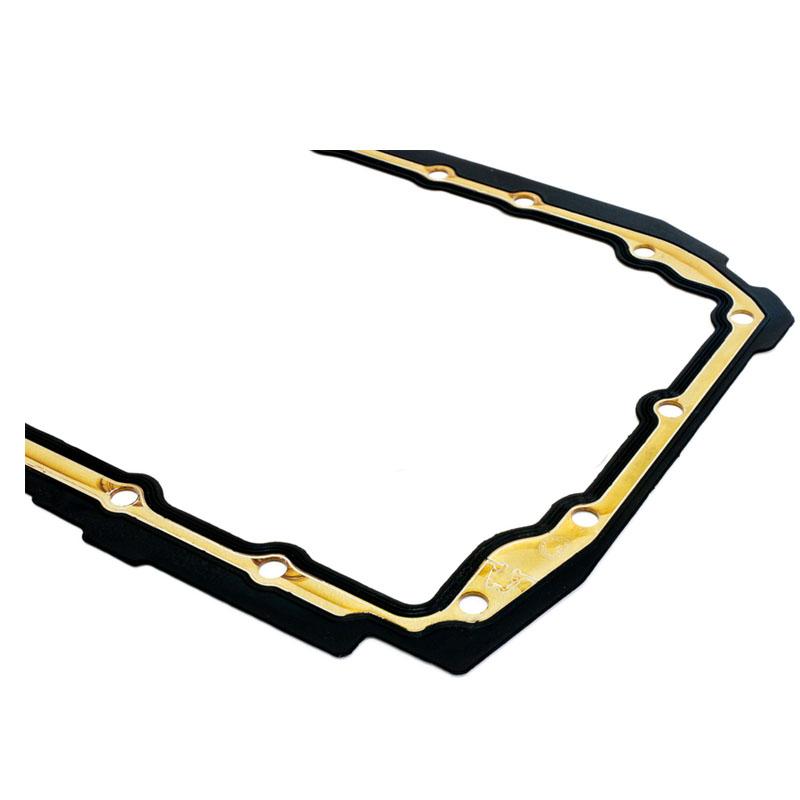

Flat Ring Gasket Design for Sealing Applications in Industrial Equipment

Understanding Flat Ring Gaskets Function, Applications, and Benefits

In the world of mechanical engineering and fluid transfer, the importance of effective sealing cannot be overstated. One of the most widely used sealing solutions is the flat ring gasket. This article delves into the features, functions, applications, and advantages of flat ring gaskets, showcasing their essential role in various industries.

What is a Flat Ring Gasket?

A flat ring gasket is a circular disc made from various materials designed to fill the space between two mating surfaces, preventing the escape of fluids or gases. Typically, these gaskets are made from materials that can withstand extreme pressure, temperature, and exposure to chemicals. Common materials used in their manufacture include rubber, silicone, graphite, and various metals, each selected based on the specific application requirements.

Functions of Flat Ring Gaskets

The primary function of a flat ring gasket is to create a reliable seal. When two surfaces are bolted together, a flat ring gasket is inserted in between. The material compresses under the clamping force of the bolts, filling any gaps and imperfections on the surface. This compression ensures that there is no leakage of fluids or gases, which is crucial for maintaining pressure and preventing contamination in mechanical systems.

In addition to sealing, flat ring gaskets also serve to manage vibrations between bolted components, offering a buffer that can absorb shock and reducing wear and tear on machinery.

Applications of Flat Ring Gaskets

Flat ring gaskets find applications across a multitude of industries, including

1. Automotive Industry These gaskets are widely used in engines, transmissions, and exhaust systems, where they must withstand high temperatures and aggressive fluid conditions.

2. Aerospace In aviation, the reliability and performance of components are critical. Flat ring gaskets are deployed in fuel systems, hydraulic systems, and airframes to provide reliable sealing solutions.

flat ring gasket

3. Oil and Gas The extraction, processing, and transportation of oil and gas require robust sealing solutions to handle the extreme pressures and corrosive environments. Flat ring gaskets are essential in pipelines, valves, and compressors.

4. Chemical Processing In chemical plants, gaskets must withstand harsh chemicals and high temperatures. Flat ring gaskets made from specialized materials are crucial for ensuring the safety and efficacy of chemical processes.

5. Manufacturing Flat ring gaskets are also used in various manufacturing equipment to prevent leaks of oils, coolants, and other fluids essential for the operation of machinery.

Advantages of Flat Ring Gaskets

The benefits of using flat ring gaskets are numerous

- Versatility With a variety of materials and designs available, flat ring gaskets can be tailored for specific environments and applications.

- Cost-Effectiveness These gaskets are generally inexpensive compared to custom sealing solutions, making them an economical choice for many applications.

- Ease of Installation Flat ring gaskets are simple to install, which saves time and reduces labor costs in manufacturing and maintenance.

- Reliable Performance When properly selected and installed, flat ring gaskets provide long-lasting seals, ensuring the safe and efficient operation of machinery.

Conclusion

Flat ring gaskets are an essential component in numerous mechanical systems, providing reliable sealing solutions across a range of industries. Their ability to accommodate various conditions, materials, and applications makes them a crucial element in ensuring the efficiency and safety of machinery. Understanding the function and benefits of flat ring gaskets can help engineers and maintenance professionals make informed decisions that enhance operational performance and mitigate risks related to leaks and failures. Whether in automotive, aerospace, oil and gas, or chemical processing, flat ring gaskets continue to prove their value in today's demanding working environments.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories