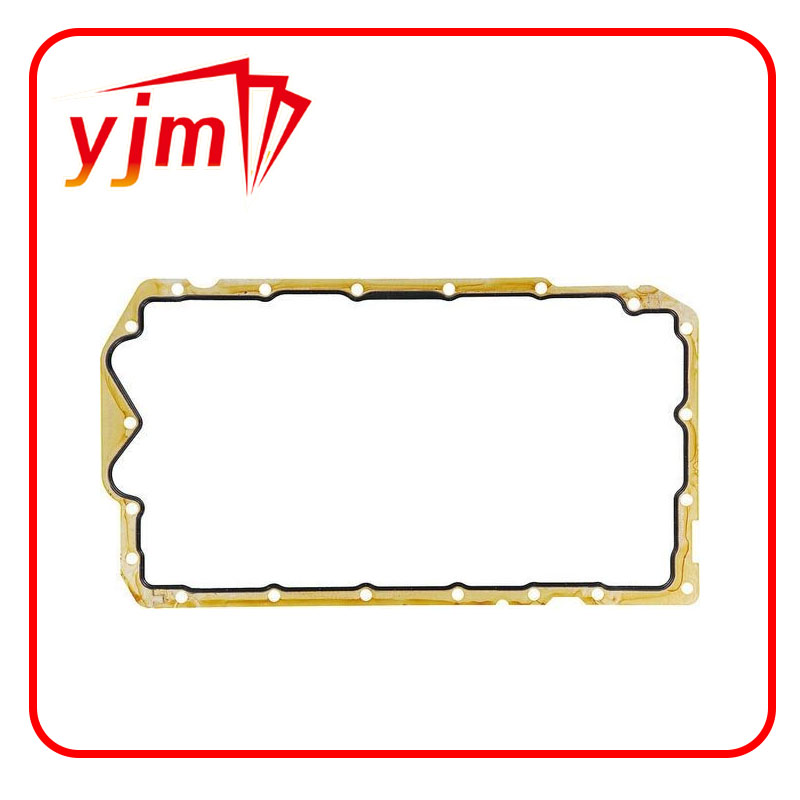

flat o ring seal

Understanding Flat O-Ring Seals A Comprehensive Overview

Flat O-ring seals are essential components in various mechanical systems. Designed primarily for sealing purposes, these rings serve critical functions in preventing the leakage of fluids and gases in numerous applications. Understanding their structure, benefits, and applications can significantly enhance the efficiency of machinery and equipment.

Understanding Flat O-Ring Seals A Comprehensive Overview

One of the primary advantages of flat O-ring seals is their versatility. They can be utilized in both static and dynamic applications. In static applications, where the components remain stationary, flat O-rings effectively prevent leakage between two surfaces. In dynamic applications, such as in pumps or hydraulic systems, they can accommodate movement while still maintaining an effective seal. This adaptability makes them suitable for a wide range of industries, including automotive, aerospace, and manufacturing.

flat o ring seal

Another notable benefit of flat O-rings is their ability to withstand harsh environments. Depending on the material used, these seals can resist extreme temperatures, chemicals, and abrasive conditions. For instance, fluorocarbon rubber (FKM) flat O-rings are ideal for high-temperature applications, while silicone flat O-rings excel in low-temperature scenarios. Selecting the right material is crucial for maximizing performance and durability.

Installation of flat O-ring seals is relatively straightforward, but attention to detail is essential. Proper surface preparation is critical to ensure a good seal. Surfaces must be clean, smooth, and free from debris to avoid compromising the seal's effectiveness. Additionally, the correct fit is vital; an oversized or undersized O-ring can lead to leaks or damage during operation. Manufacturers often provide guidelines on the appropriate sizing and installation techniques to help users achieve optimal results.

Moreover, maintenance of flat O-ring seals is vital for ensuring longevity and peak performance. Regular inspections can help identify signs of wear, such as cracking, hardening, or deformation, which can indicate that replacement is necessary. Keeping a stock of replacement seals on hand can minimize downtime during maintenance.

In conclusion, flat O-ring seals are fundamental components in many mechanical systems, offering unique advantages due to their design and material properties. Their ability to provide effective sealing in both static and dynamic applications makes them invaluable in various industries. Understanding their features, proper installation, and maintenance will go a long way in ensuring the reliability and efficiency of machinery. As technology progresses, the innovation surrounding sealing solutions continues to evolve, promising even greater performance and durability in the future.

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

-

The Essential Guide to Marine Bearings and Boat Trailer Wheel Bearings

News Jul.31,2025

-

The Complete Guide to Heavy Duty Seals: Protecting Doors and Spaces Efficiently

News Jul.31,2025

-

Essential Guide to Marine Shaft Bearings and Boat Trailer Axle Bearings

News Jul.31,2025

-

Comprehensive Guide to Marine and Trailer Bearings for Safe Boating and Transport

News Jul.31,2025

-

Comprehensive Guide to Automotive Oil Seals: Protecting Your Engine and Shafts

News Jul.31,2025

-

Understanding Automotive Oil Seals: Essential Components for Engine and Shaft Protection

News Jul.30,2025

Products categories