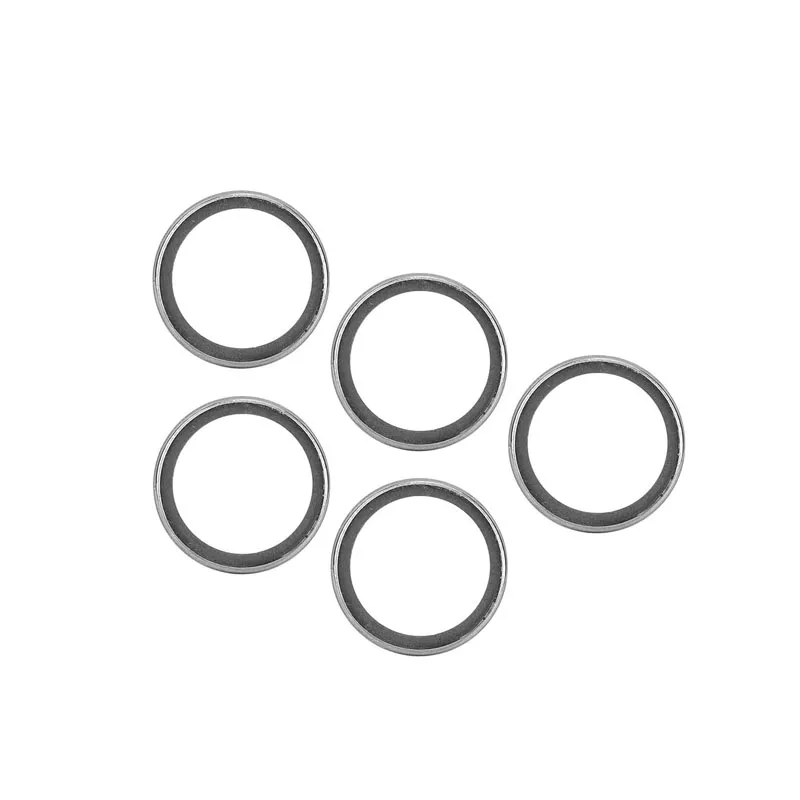

flat o ring seal

Understanding Flat O-Ring Seals An Essential Component in Mechanical Engineering

In the realm of mechanical engineering and fluid dynamics, seals play a critical role in ensuring the integrity and performance of systems. Among various types of seals, the flat O-ring seal has gained prominence due to its unique design, versatility, and efficiency in preventing leaks in various applications. This article delves into the characteristics, advantages, applications, and considerations associated with flat O-ring seals.

Characteristics of Flat O-Ring Seals

Flat O-ring seals are essentially circular elastomeric rings that are designed to have a flat cross-section instead of the traditional round profile. This flat design allows for a larger surface area, enhancing the seal's contact with mating surfaces and optimizing its sealing capabilities. Typically produced from materials like rubber or silicone, these seals are available in a myriad of sizes, hardness levels, and material compositions, making them suitable for diverse applications across various industries.

Advantages of Flat O-Ring Seals

1. Reduced Extrusion Risk One of the significant benefits of flat O-ring seals is their reduced tendency to extrude, especially in high-pressure situations where traditional round O-rings may be prone to deformity and failure. This quality ensures a more reliable seal under varying operational conditions.

2. Enhanced Load Distribution The flat design allows for better load distribution across the sealing surface. This characteristic minimizes local stress concentrations and extends the lifespan of both the seal and the mating surfaces.

3. Ease of Installation Flat O-ring seals are easier to install compared to their round counterparts, reducing the risk of damage during assembly. They can be positioned without requiring complicated tooling or techniques.

flat o ring seal

4. Chemical Resistance Depending on the material used, flat O-ring seals can exhibit excellent resistance to various chemicals, making them suitable for applications involving corrosive fluids or gases.

Applications of Flat O-Ring Seals

Flat O-ring seals find utility in numerous sectors, including automotive, aerospace, oil and gas, and manufacturing. In the automotive industry, they are commonly used in fuel systems, hydraulic systems, and engine components, where reliable sealing is paramount to prevent leaks and maintain operational efficiency. In aerospace applications, flat O-rings are utilized in hydraulic systems and environmental control systems, where they ensure the safe and effective performance of critical components.

Additionally, these seals play a vital role in industrial machinery and equipment, where they help maintain the integrity of pneumatic and hydraulic systems, thereby preventing downtime due to leaks or failures.

Considerations for Use

When selecting a flat O-ring seal, several factors must be considered, including the operational pressure, temperature, and the type of fluids involved in the application. Additionally, proper installation and maintenance practices are crucial to ensure the longevity and effectiveness of these seals.

Conclusion

In summary, flat O-ring seals are an indispensable component in various mechanical systems, providing reliable sealing solutions across multiple industries. Their distinctive flat design offers several advantages, including reduced extrusion, enhanced load distribution, and ease of installation. As industries continue to advance and demand more efficient solutions, flat O-ring seals are poised to play an even more significant role in the future of mechanical engineering and fluid dynamics. Understanding their features and applications is essential for engineers and technicians aiming to optimize system performance and reliability.

-

Understanding the Front Main Engine Seal: Purpose, Maintenance, and Installation

News Jul.29,2025

-

Understanding O-Rings and Seal Rings: Types, Applications, and Custom Solutions

News Jul.29,2025

-

Understanding Crankshaft Oil Seals: Rear Seals, Pulley Seals, and Their Role in Engine Integrity

News Jul.29,2025

-

The Importance of Front and Rear Crankshaft Seals in Engine Performance and Oil Management

News Jul.29,2025

-

Crank Oil Seals: Functions, Types, and Cost Considerations in Engine Maintenance

News Jul.29,2025

-

A Comprehensive Guide to O-Rings and Seals: Types, Materials, and Global Applications

News Jul.29,2025

-

Mastering Diesel and Performance Engine Maintenance: A Guide to Critical Oil Gaskets

News Jul.28,2025

Products categories