Flat O-Ring Seal Design and Applications in Various Industries

Understanding Flat O-Ring Seals A Comprehensive Guide

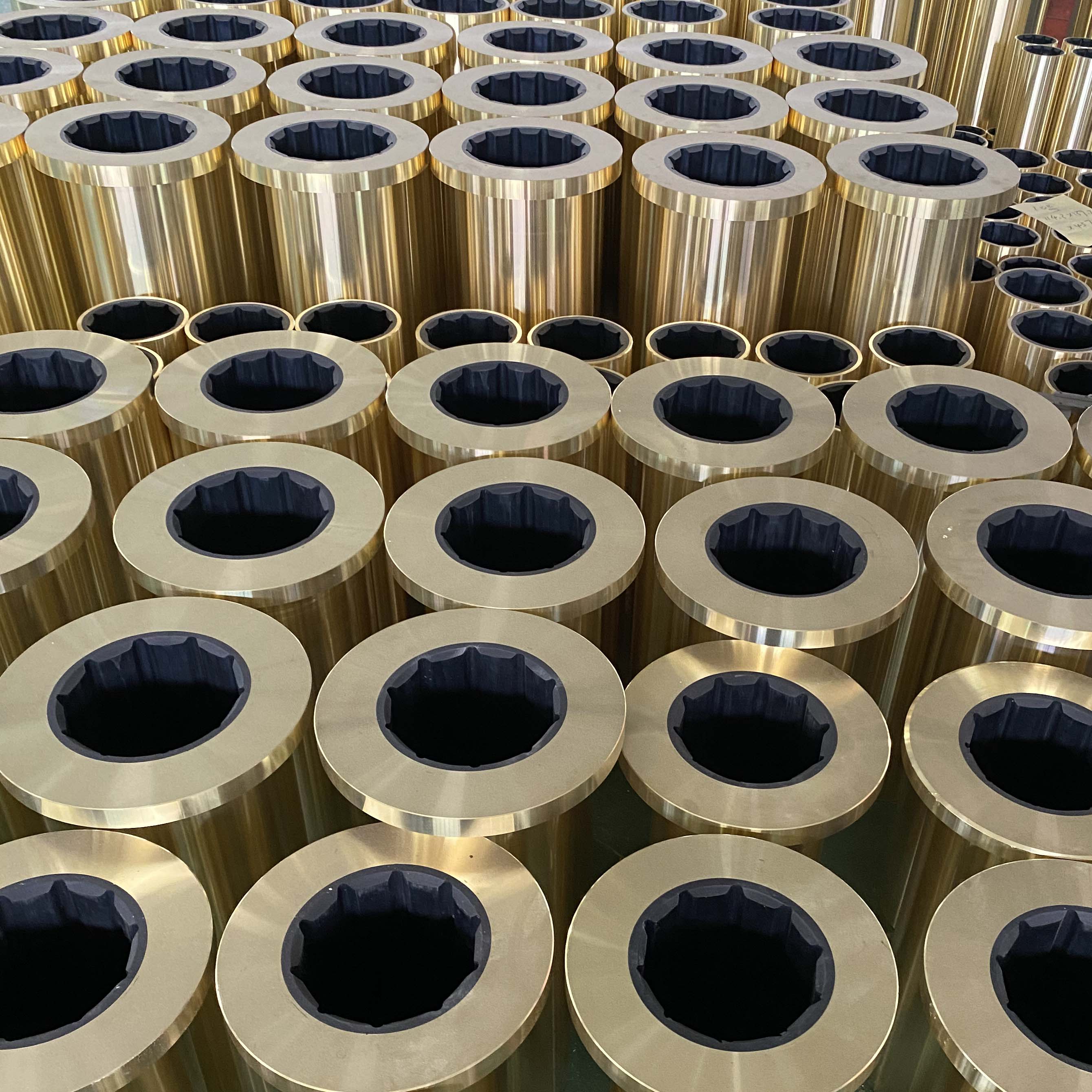

Flat O-ring seals are a vital component in various industrial applications, serving as essential elements for ensuring airtight and leak-proof seals. Unlike traditional round O-rings, flat O-rings possess a non-circular profile, offering distinct advantages in specific environments and applications. This article explores the characteristics, applications, benefits, and considerations for using flat O-ring seals.

Characteristics of Flat O-Ring Seals

Flat O-ring seals are typically made from elastomeric materials such as rubber, silicone, or thermoplastics. Their design features a uniform cross-section that can vary in thickness and diameter, making them suitable for a wide range of sealing requirements. The flat profile allows these seals to conform more easily to mating surfaces, which can be advantageous in situations where space constraints exist.

One of the primary characteristics of flat O-ring seals is their excellent resistance to various conditions, including temperature extremes, harsh chemicals, and environmental factors. Depending on the material selected, they can withstand high pressures and provide long-lasting performance, which is crucial in applications demanding durability and reliability.

Applications of Flat O-Ring Seals

Flat O-ring seals find extensive use in numerous industries, including automotive, aerospace, oil and gas, pharmaceuticals, and food processing. Some common applications include

1. Automotive Industry In vehicles, flat O-rings are used in fuel systems, hydraulic systems, and engine components. They effectively seal critical elements, preventing leaks that could lead to performance issues or safety hazards.

2. Aerospace The aerospace sector demands precision, where flat O-rings are used to create reliable seals within engines and hydraulic systems. Their ability to withstand extreme temperatures and pressures makes them ideal for this rigorous environment.

3. Oil and Gas In the oil and gas industry, flat O-ring seals are employed in pipelines, drilling equipment, and refineries. Given the corrosive nature of the fluids and gases involved, these seals provide essential protection against leaks.

4. Pharmaceuticals and Food Processing In these industries, maintaining hygiene is crucial. Flat O-rings are utilized in equipment and containers that require sterile seals to prevent contamination.

Benefits of Using Flat O-Ring Seals

The adoption of flat O-ring seals offers numerous benefits

flat o ring seal

- Versatility Their customizable dimensions allow flat O-rings to adapt to a wide variety of applications, making them a versatile choice for manufacturers

.- Enhanced Performance The flat design improves contact with mating surfaces, leading to a tighter seal and reducing the risk of leaks.

- Reduced Friction Flat O-rings can be designed to minimize friction, which is particularly beneficial in dynamic applications where movement occurs.

- Durability Many materials used for flat O-rings are known for their longevity, reducing the need for frequent replacements and maintenance.

Considerations for Selection and Use

While flat O-ring seals offer many advantages, several factors should be considered when selecting them for specific applications

1. Material Compatibility It's essential to choose a material that is compatible with the substances involved, including temperatures, pressures, and chemical exposures.

2. Design Specifications Ensure that the seal's dimensions match the application's requirements, including the thickness and diameter.

3. Installation Procedures Proper installation is critical to achieving the desired sealing performance. Misalignment or improper handling can lead to seal failure.

4. Regular Maintenance Depending on the application, routine inspections and maintenance can help identify wear or damage, ensuring continued performance.

Conclusion

Flat O-ring seals play an indispensable role in various industries, offering effective sealing solutions with significant versatility and durability. By understanding their characteristics, applications, and benefits, manufacturers and engineers can make informed decisions regarding their use, ultimately enhancing the efficiency and reliability of their systems. Whether in high-pressure environments or sensitive sanitary applications, flat O-ring seals continue to be a go-to choice for reliable sealing solutions.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories