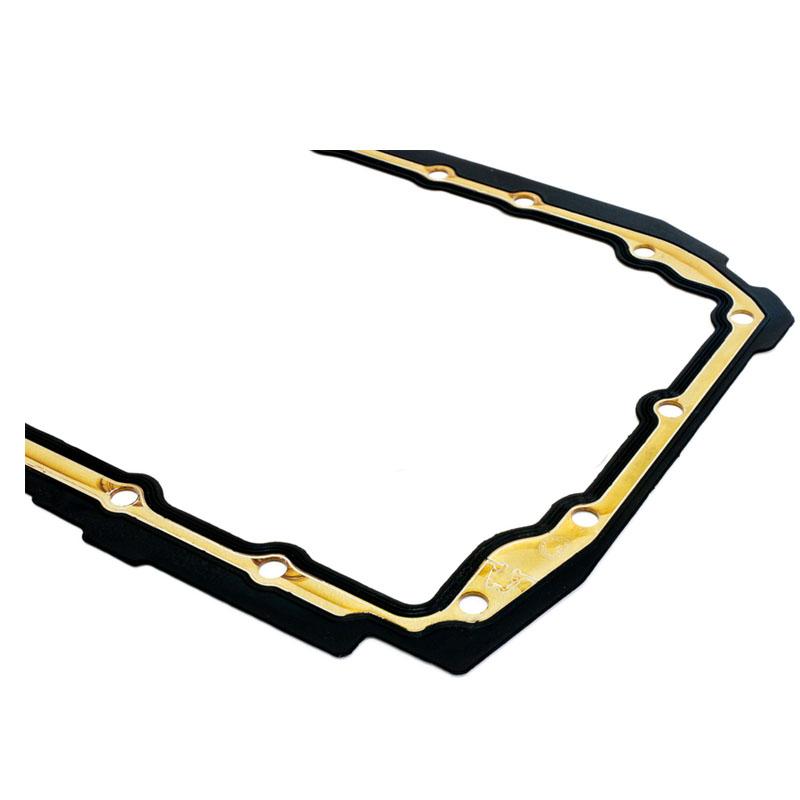

flat o ring gasket

Understanding Flat O-Ring Gaskets A Comprehensive Overview

Flat O-Ring gaskets are essential components in various industrial applications, providing effective sealing solutions that prevent leaks and ensure the integrity of mechanical assemblies. These gaskets are characterized by their circular shape, which resembles a standard O-Ring, but they typically have a flat profile. This design allows them to fit securely between two mating surfaces, providing a reliable seal when compressed. This article delves into the importance, applications, materials, and advantages of Flat O-Ring gaskets.

Importance of Flat O-Ring Gaskets

The primary function of any gasket is to create a seal that prevents the escape of fluids or gases between two surfaces under pressure. Flat O-Ring gaskets are particularly valued for their versatility and durability. They are engineered to withstand various operating conditions, including extremes of temperature and pressure, making them suitable for an array of environments. The sealing effectiveness of Flat O-Ring gaskets is crucial in maintaining system efficiency and safety, especially in high-stakes applications such as automotive, aerospace, and petrochemical industries.

Applications of Flat O-Ring Gaskets

Flat O-Ring gaskets find applications across multiple sectors due to their effective sealing properties. Some notable applications include

1. Automotive Industry These gaskets are widely used in engines and fuel systems, where preventing leaks is critical for optimal performance and safety. Flat O-Ring gaskets are commonly used in fuel pumps, oil pans, and pressure regulators.

2. Aerospace In aircraft systems, where reliability is paramount, Flat O-Ring gaskets are used to seal fuel tanks, hydraulic systems, and pneumatic applications, ensuring that fluids do not leak under varying atmospheric conditions.

3. Industrial Equipment Manufacturing machines, boilers, and compressors often utilize Flat O-Ring gaskets to maintain pressure and enhance performance. They are ideal for static applications where they can effectively seal flanges and junctions.

4. Food and Beverage In the food industry, it is crucial to use gaskets that meet health and safety regulations. Flat O-Ring gaskets made from food-grade materials are used in processing equipment, ensuring that there are no contaminants in the products.

Materials Used in Flat O-Ring Gaskets

The effectiveness of Flat O-Ring gaskets significantly depends on the materials from which they are made

. Common materials includeflat o ring gasket

1. Rubber Various rubber compounds, such as nitrile (NBR), silicone, and EPDM, are frequently used for O-Ring gaskets due to their flexibility and resistance to environmental factors.

2. PTFE Polytetrafluoroethylene (PTFE) offers excellent chemical resistance and is ideal for applications where aggressive chemicals are involved.

3. Metal In high-temperature applications, metal gaskets can provide superior durability while still offering the sealing properties of O-Rings.

4. Composite Materials Often used in specialized applications, composite materials can be designed to tailor specific properties such as temperature resistance, strength, or flexibility.

Advantages of Flat O-Ring Gaskets

Flat O-Ring gaskets offer several notable advantages

1. Easy Installation The flat profile allows for straightforward alignment with mating surfaces, simplifying the installation process.

2. Cost-Effectiveness Compared to other gasket types, Flat O-Ring gaskets can be more economical due to their simple design and materials, contributing to reduced production costs.

3. Versatility They can be used across a broad range of applications and can be customized in size and material to suit specific needs.

4. Durability Designed to withstand wear and tear from environmental factors, Flat O-Ring gaskets have a long service life, reducing the necessity for frequent replacements.

Conclusion

Flat O-Ring gaskets play a vital role in ensuring that machinery and systems operate efficiently by preventing leaks and maintaining proper sealing in various applications. Their availability in multiple materials and their ease of installation enhance their desirability across industries. As technology advances, the design and manufacturing processes of these gaskets continue to improve, promising even more effective sealing solutions for the challenges of the future. Appreciating the significance of Flat O-Ring gaskets enables engineers and technicians to make informed decisions in material selection and application design, ultimately contributing to safer and more efficient industrial operations.

-

The Ultimate Guide to Car Repair Kits: Tools and Essentials Every Driver Should Own

News Aug.01,2025

-

The Complete Guide to Oil Pan Gaskets: Sealing Engine Leaks the Right Way

News Aug.01,2025

-

Preventing Oil Leaks: A Complete Guide to Oil Pan Gaskets and Drain Seals

News Aug.01,2025

-

Everything You Need to Know About Oil Pan Gaskets and Drain Plug Seals

News Aug.01,2025

-

Essential for Car Owners: How to Use a Car Repair Kit to Deal with Minor Breakdown

News Aug.01,2025

-

Comprehensive Guide to Engine Oil Sump Gaskets and Related Seals

News Aug.01,2025

-

The Ultimate Guide to Boat Propeller Bearings and Trailer Wheel Bearings

News Jul.31,2025

Products categories